CNC Machining

CNC Machining

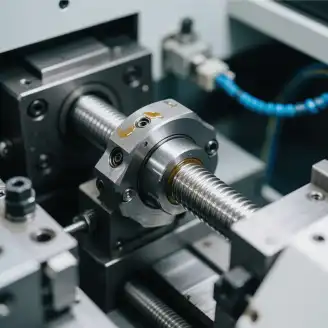

1. CNC Machining Capabilities Overview

We provide high-precision CNC milling, turning, and multi-axis machining services for prototypes and mass production. With 20+ CNC machines (including 3/4/5-axis and Swiss-type lathes), we support complex geometries with tolerances as tight as ±0.005 mm.

Key Strengths:

✅ Source Factory Advantage: Full control over production (no middlemen), ensuring lower costs and faster lead times.

✅ OEM/ODM Expertise: Dedicated R&D team for custom solutions, from design optimization to post-processing.

✅ One-Stop Service: Includes material procurement, machining, finishing, and export-ready packaging.

2. Materials & Finishes

Materials Available

|

Metal |

Plastic |

Other |

|

Aluminum 6061, 7075 |

ABS |

Delrin (POM) |

|

Stainless Steel 303/304/316 |

Nylon |

PTFE |

|

Brass, Copper |

PEEK |

Polycarbonate |

Surface Finishing Options

Aesthetic: Polishing, Bead Blasting, Brushing

Functional: Hard Anodizing (up to 50μm), Electroless Nickel Plating

Protective: Powder Coating, Passivation (for stainless steel)

3. CNC Machining Processes

|

Process |

Tolerance |

Applications |

|

3/4/5-Axis Milling |

±0.01 mm |

Aerospace brackets, engine parts |

|

CNC Turning |

±0.005 mm |

Shafts, bushings, hydraulic fittings |

|

Swiss Machining |

±0.002 mm |

Medical screws, micro-components |

|

EDM (Wire & Sinker) |

±0.003 mm |

Mold inserts, hardened steel parts |

4. Industries We Serve

Automotive: Gearbox housings, brake components

Aerospace: Lightweight aluminum frames, turbine parts

Industrial Machinery: Pump bodies, hydraulic valves

Medical: FDA-compliant surgical instruments

5. Quality Assurance & Certifications

ISO 9001:2015 certified production facility

100% Inspection: CMM, optical comparators, roughness testers

Full Documentation: Material certs (MTC), PPAP, and FAIR reports for OEM clients

6. How It Works

Upload Your Design: Send CAD files (STEP, IGES, X_T) for free DFM analysis.

Get a Quote: Pricing & lead time within 48 hours.

Delivery time:prototypes in 1-2weeks, mass production in 4-7 weeks.

Production & QC: Machining with real-time updates.

Delivery: Worldwide shipping with EXW/FOB/DDP terms.

Why Choose Us Over Competitors?

Cost Savings: 20-30% lower than traders (factory-direct pricing).

Speed: 70% of urgent orders shipped on time.

OEM Support: Engineering team assists with design-for-manufacturability (DFM).

Request a Quote Now → [kshdhardware@qdkshd.com]