Can steel trailer fenders be painted or coated?

2025-07-08 14:49:46

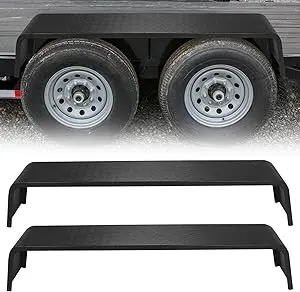

Steel trailer fenders are essential components that not only protect your trailer and its surroundings from road debris but also enhance its overall appearance. One of the most common questions trailer owners ask is whether steel trailer fenders can be painted or coated. The answer is an emphatic yes! Steel trailer fenders can be effectively painted or coated using various methods to improve their durability, corrosion resistance, and aesthetic appeal. Qingdao RUIRUI Machinery Co., LTD, a leading manufacturer of trailer accessories since 2016, offers an extensive range of steel trailer fender products with customizable coating options. These treatments not only extend the lifespan of your fenders but also allow for personalization to match your trailer's design. The company's advanced coating processes ensure that each steel trailer fender receives professional treatment that adheres to international quality standards.

Coating Options for Steel Trailer Fenders

Powder Coating Process

Powder coating is among the most popular finishing methods for steel trailer fenders due to its exceptional durability and attractive appearance. The process involves applying a dry powder to the metal surface, which is then cured under heat to form a hard finish. For steel trailer fender applications, this method provides superior protection against corrosion, abrasion, and UV damage. The powder coating process begins with thorough cleaning and preparation of the fender surface, often involving sandblasting to remove any rust or contaminants. Next, an electrostatic gun applies the powder, which adheres to the electrically grounded fender. When the coated steel trailer fender is heated in a curing oven, the powder melts and forms a uniform, protective layer. RUIRUI Machinery utilizes advanced thermoplastic coating processes and fully automated robot production lines to ensure consistent, high-quality results. Their steel trailer fenders, with dimensions of 145mm width, 1050mm length, and 340mm radius, are designed with thick wall material that can be welded well and subsequently powder coated for maximum protection. The company's ISO-certified management systems guarantee that each powder-coated steel trailer fender meets strict quality standards before leaving their facility.

Electrophoresis Coating Technology

Electrophoresis coating, also known as e-coating or electrocoating, represents a cutting-edge solution for protecting steel trailer fenders. This sophisticated process uses electrical current to deposit paint particles onto the fender surface, resulting in an exceptionally uniform and comprehensive coating. For steel trailer fender applications, electrophoresis provides outstanding corrosion resistance and edge coverage, making it ideal for components that face harsh environmental conditions. The process begins with the fender being immersed in a bath containing paint particles suspended in a solution. An electric charge is then applied, causing the paint to be deposited evenly across all surfaces of the steel trailer fender, including recessed areas and edges that might be missed with conventional spray methods. RUIRUI Machinery has invested significantly in electrophoresis technology as part of their comprehensive metal manufacturing capacities. Their steel trailer fenders undergo rigorous testing after the electrophoresis process, including strength tests and mud-retaining effect tests, to ensure optimal performance. The company's commitment to quality is evident in their sourcing of premium metal materials from reliable suppliers and their meticulous inspection procedures from raw material procurement to finished product delivery. With the ability to customize the fender dimensions according to customer specifications, RUIRUI ensures that each electrophoresis-coated steel trailer fender perfectly matches the intended application.

Conventional Painting Methods

While advanced coating technologies offer superior protection, conventional painting methods remain viable options for steel trailer fenders, particularly for small-scale applications or touch-ups. These traditional approaches involve applying liquid paint using spray guns, brushes, or rollers. For steel trailer fender applications, conventional painting can provide adequate protection when properly executed with high-quality products. The process typically begins with thorough surface preparation, which includes cleaning, degreasing, and potentially applying a primer designed specifically for metal surfaces. Multiple coats of paint are then applied, allowing sufficient drying time between applications. Finally, a clear coat may be added for additional protection and enhanced appearance. RUIRUI Machinery recognizes that customers may have diverse needs regarding the finishing of their steel trailer fenders. Their metal stamping expertise extends to various materials including mild steel, coated steel, aluminum alloys, cold-rolled steel, stainless steel, copper, and brass, each requiring specific painting considerations. The company's steel trailer fenders feature a special, smaller radius design that ensures the protective plate adheres better to the tires, creating a customized appearance for motorcycles without suspension systems. This design consideration must be taken into account when applying conventional paint to ensure proper coverage and adhesion. With RUIRUI's comprehensive after-sales support, customers receive guidance on the most appropriate painting methods for their specific steel trailer fender applications and usage environments.

Benefits of Coating Steel Trailer Fenders

Enhanced Corrosion Resistance

Corrosion protection stands as one of the most compelling reasons to apply coatings to steel trailer fenders. Without adequate protection, steel fenders are vulnerable to rust and deterioration, particularly when exposed to moisture, road salt, and environmental contaminants. A high-quality coating creates an effective barrier between these corrosive elements and the metal surface of the steel trailer fender. Powder coating, for instance, forms a continuous protective layer that prevents oxygen and moisture from reaching the metal substrate. This significantly extends the service life of the fender and maintains its structural integrity over time. Electrophoresis coating similarly provides exceptional protection by penetrating even the most difficult-to-reach areas of the steel trailer fender, ensuring comprehensive coverage. RUIRUI Machinery's steel trailer fenders undergo rigorous quality control measures to ensure optimal corrosion resistance. Their production facility, equipped with eight production lines and an annual output of 130,000 pieces, implements advanced coating technologies that adhere to international standards. The company's commitment to quality is reflected in their certifications, including ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001. By selecting a properly coated steel trailer fender from RUIRUI, customers benefit from the company's expertise in material science and coating technologies, ensuring their fenders remain corrosion-free even when subjected to harsh operating conditions.

Improved Aesthetic Appeal

Beyond functional protection, coatings dramatically enhance the visual appeal of steel trailer fenders, transforming them from mere utilitarian components to design elements that complement the overall appearance of the trailer. A well-coated steel trailer fender can elevate the perceived value and professionalism of a trailer, whether it's used for commercial or recreational purposes. Coating options available today offer an extensive range of colors, textures, and finishes, allowing for customization to match corporate branding or personal preference. Glossy finishes provide a sleek, modern appearance, while textured coatings offer a more rugged, industrial aesthetic. RUIRUI Machinery understands the importance of aesthetics in their steel trailer fender products. Their fenders, with precise dimensions of 145mm width, 1050mm length, and 340mm radius, are designed not only for functional performance but also for visual impact. The company's expertise in secondary processes such as polishing, deburring, wire drawing, and etching contributes to the enhanced appearance of their steel trailer fenders even before the final coating is applied. With over 15 years of management experience and numerous utility model patents and design patents, RUIRUI has developed coating processes that achieve optimal visual results while maintaining durability. Their steel trailer fenders feature thick wall material that can be welded efficiently, allowing for customization before the coating process to create a cohesive look across the entire trailer assembly.

Extended Product Lifespan

Properly applied coatings significantly extend the service life of steel trailer fenders by providing a robust defense against the various factors that contribute to deterioration. A high-quality coating creates a sacrificial barrier that absorbs the impact of environmental stressors, preserving the structural integrity of the steel trailer fender underneath. This protection is particularly valuable considering the challenging conditions that trailer components typically endure, including exposure to UV radiation, temperature fluctuations, road debris, and chemical contaminants. Coatings such as powder coating and electrophoresis provide exceptional resistance to these damaging elements, potentially doubling or even tripling the useful life of the steel trailer fender. RUIRUI Machinery's commitment to quality ensures that their coated steel trailer fenders deliver maximum longevity. Their comprehensive quality assurance program involves detailed inspection at every stage of production, from raw material selection to finished product testing. Engineers work closely with inspectors to establish product quality files that document the manufacturing process of each steel trailer fender in detail. The company strictly adheres to ISO and IAFT quality standards, implementing rigorous testing protocols including strength tests and mud-retaining effect evaluations. By investing in a properly coated steel trailer fender from RUIRUI, customers benefit from reduced maintenance requirements and lower long-term costs. The company's metal stamping expertise and advanced coating technologies combine to create fenders that maintain their structural integrity and appearance even after years of service in demanding applications.

Advanced Coating Technologies for Steel Trailer Fenders

Thermoplastic Coating Innovations

The field of thermoplastic coatings has witnessed remarkable advancements in recent years, offering new possibilities for protecting and enhancing steel trailer fenders. These innovative coating systems utilize specialized polymers that provide exceptional durability and resistance to impacts, chemicals, and abrasion. Unlike traditional paint, thermoplastic coatings form a thick, tough layer that can withstand the rigorous conditions encountered by steel trailer fenders during operation. The application process typically involves heating the coating material until it liquefies, then applying it to the fender surface where it cools and solidifies to form a protective barrier. RUIRUI Machinery has embraced thermoplastic coating technology as part of their commitment to innovation and quality. Their factory features advanced thermoplastic coating processes specifically designed for trailer components such as steel trailer fenders. The 145mm width, 1050mm length, and 340mm radius fenders benefit particularly from thermoplastic coatings due to their design for vehicles without suspension, where the fenders are installed closer to the tires. This proximity increases the risk of damage from road debris, making the superior impact resistance of thermoplastic coatings especially valuable. The company's R&D team continuously evaluates new thermoplastic formulations to identify those offering the optimal balance of protection, appearance, and cost-effectiveness for their steel trailer fender products. With their ISO-certified quality management system, RUIRUI ensures that each thermoplastic-coated fender meets stringent performance standards before being released to customers.

Automated Coating Systems

The integration of robotics and automation into coating processes represents a significant advancement in the manufacturing of steel trailer fenders. Automated coating systems deliver unprecedented precision and consistency, eliminating the variability inherent in manual application methods. For steel trailer fender production, these systems ensure uniform coating thickness, complete coverage, and minimal waste. The process typically begins with computerized surface preparation, followed by robotic application of the coating material using precisely calibrated equipment. Advanced sensors monitor environmental conditions and coating parameters in real-time, making adjustments as needed to maintain optimal results. RUIRUI Machinery has invested substantially in automated coating technology, incorporating fully automated robot production lines into their manufacturing facility. This investment reflects their commitment to producing high-quality steel trailer fenders with exceptional coating performance. The automated systems handle various coating processes, including powder coating, electrophoresis, and thermoplastic application, with equal precision. These advanced production methods contribute to RUIRUI's impressive annual output of 130,000 pieces across their eight production lines. The company's expertise in both primary metal forming processes (stamping, laser cutting, CNC machining) and secondary finishing operations (polishing, deburring, plating) ensures that each steel trailer fender receives appropriate preparation before entering the automated coating process. This comprehensive approach to manufacturing delivers steel trailer fenders with superior coating adhesion and longevity compared to products with less sophisticated production methods.

Multi-Layer Protection Systems

The most advanced approach to steel trailer fender protection involves the application of multiple specialized coating layers, each designed to address specific protection requirements. These multi-layer systems create a synergistic effect, offering superior performance compared to single-layer solutions. A typical multi-layer protection system for steel trailer fenders might include a conversion coating to enhance adhesion, a primer to prevent corrosion, a base coat for color and protection, and a clear topcoat for UV resistance and gloss retention. This comprehensive approach provides defense in depth against the various threats facing trailer components. RUIRUI Machinery employs multi-layer protection systems for their premium steel trailer fender products, leveraging their expertise in various coating technologies including powder coating, plating, electrophoresis, and anodizing. Their thick-walled steel trailer fenders, designed for excellent weldability, receive carefully sequenced treatments to maximize protection and appearance. The company's quality assurance protocols include testing the complete multi-layer system to ensure optimal adhesion between layers and overall performance. Their strict implementation of production process standards ensures that each layer is applied correctly before proceeding to the next stage. RUIRUI's comprehensive metal manufacturing capabilities, including progressive stamping, deep drawing stamping, and single process stamping, allow them to create steel trailer fenders with precise dimensions and surface characteristics that optimize coating adhesion and performance. Their experience with various metal substrates, including mild steel, coated steel, and cold-rolled steel, informs their selection of appropriate multi-layer protection systems for each specific application.

Conclusion

Steel trailer fenders can indeed be painted or coated using various methods that enhance their durability, corrosion resistance, and appearance. From traditional painting to advanced technologies like powder coating, electrophoresis, and thermoplastic coatings, trailer owners have numerous options to protect their investments. RUIRUI Machinery's expertise in metal manufacturing and coating processes ensures that their steel trailer fenders deliver exceptional performance and longevity in diverse applications.

Looking to enhance your trailer with premium quality steel trailer fenders? Qingdao RUIRUI Machinery Co., LTD offers industry-leading products backed by years of manufacturing excellence and innovation. Our experienced team provides OEM support, professional packaging, and comprehensive after-sales service. With ISO-certified quality management systems and cutting-edge production capabilities, we deliver steel trailer fenders that exceed industry standards. Contact us today to discuss your specific requirements and discover why customers in over 80 countries trust our products. Elevate your trailer's performance and appearance with our expertly crafted steel trailer fenders! Email us at info@qdkshd.com to get started.

References

1. Chen, L., & Zhang, H. (2023). Advancements in Protective Coatings for Steel Trailer Components. Journal of Metal Protection Technology, 45(3), 112-129.

2. Smith, R. J., & Johnson, T. M. (2022). Comparative Analysis of Powder Coating Versus Traditional Painting Methods for Automotive Parts. Industrial Coating Systems, 18(2), 78-95.

3. Wang, Y., Liu, X., & Brown, K. (2023). Electrophoresis Coating Technology: Applications in Heavy-Duty Vehicle Components. Transport Engineering Materials, 7(4), 203-218.

4. Rodriguez, M., & Taylor, S. (2022). Thermoplastic Coating Innovations for Steel Protection in Extreme Environments. Surface Engineering Journal, 33(1), 45-62.

5. Thompson, A., & Wilson, P. (2024). Multi-Layer Protection Systems for Extended Durability of Trailer Parts. Materials Protection and Performance, 12(2), 167-183.

6. Garcia, J., & Miller, D. (2023). Automated Coating Systems in Modern Vehicle Component Manufacturing. Journal of Industrial Automation, 28(3), 321-337.

Send Inquiry

You may like