Stainless Steel Square U Bolts

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Stainless Steel Square U Bolts - Premium Industrial Fasteners for Square Applications

Qingdao Ruirui Machinery Manufacturing Co., Ltd. brings you premium Stainless Steel Square U Bolts engineered for superior performance in demanding industrial environments. With our 20+ years of manufacturing expertise and ISO 9001:2015 certification, we deliver specialized fasteners that solve critical challenges in marine, solar, and industrial applications. Our square geometry design provides full surface contact on square tubing and box beams, preventing rotation and deformation while ensuring even load distribution. Built from Grade 304 and 316 stainless steel with tensile strength ranging 500-800 MPa, these bolts offer exceptional corrosion resistance and structural integrity for your most demanding projects.

What Makes Our Stainless Steel Square U Bolts Superior?

Advanced Engineering Design

Our bolts feature flat-bottomed geometry that perfectly matches square-profiled materials. This eliminates the point-loading issues you face with round U-bolts on square pipes. The result? Better stability and longer service life for your installations.

Premium Material Selection

We craft our products using austenitic stainless steel grades:

· Grade 304 (A2-70): Perfect for standard outdoor applications

· Grade 316 (A4-70/80): Enhanced with 2% molybdenum for superior marine environment resistance

Precision Manufacturing

Our CNC machining capabilities ensure tolerances as tight as ±0.005mm. Every bolt undergoes first article inspection and batch sampling per AQL standards before reaching you.

Technical Specifications

|

Parameter |

Specification |

|

Technology |

Precision Forging |

|

Material |

Stainless Steel 304/316 |

|

Tensile Strength |

500-800 MPa |

|

Temperature Resistance |

Up to 870°C (Grade 304) |

|

Surface Finish |

Passivated/Electropolished |

|

Standards Compliance |

DIN 3570, ASME B18.31.5 |

|

MOQ |

1,000 pieces |

|

Quality Certification |

ISO 9001:2015 |

Key Applications

Marine & Coastal Projects

Your boat trailers and yacht configurations need fasteners that won't fail in saltwater environments. Our Grade 316 products prevent galvanic corrosion when securing boat rollers, keel pads, and square axle beams to aluminum trailers.

Solar Mounting Systems

Solar installations require 25+ year reliability. Our bolts clamp square torque tubes and racking rails while maintaining precise panel alignment under wind loads. The stainless construction matches your solar panel warranty period.

Food Processing Equipment

Hygiene-critical environments demand non-porous surfaces that resist bacterial growth. Our bolts secure guide rails and square conduit in washdown areas while meeting FDA/HACCP protocols.

Industrial Machinery

From conveyor systems to structural frameworks, our Stainless Steel Square U Bolts provide reliable anchoring for square-profiled components in chemical plants and manufacturing facilities.

Manufacturing Advantages

Source Factory Direct

You eliminate middleman costs and get 20-30% savings compared to trading companies. Our factory-direct pricing gives you competitive advantages in your projects.

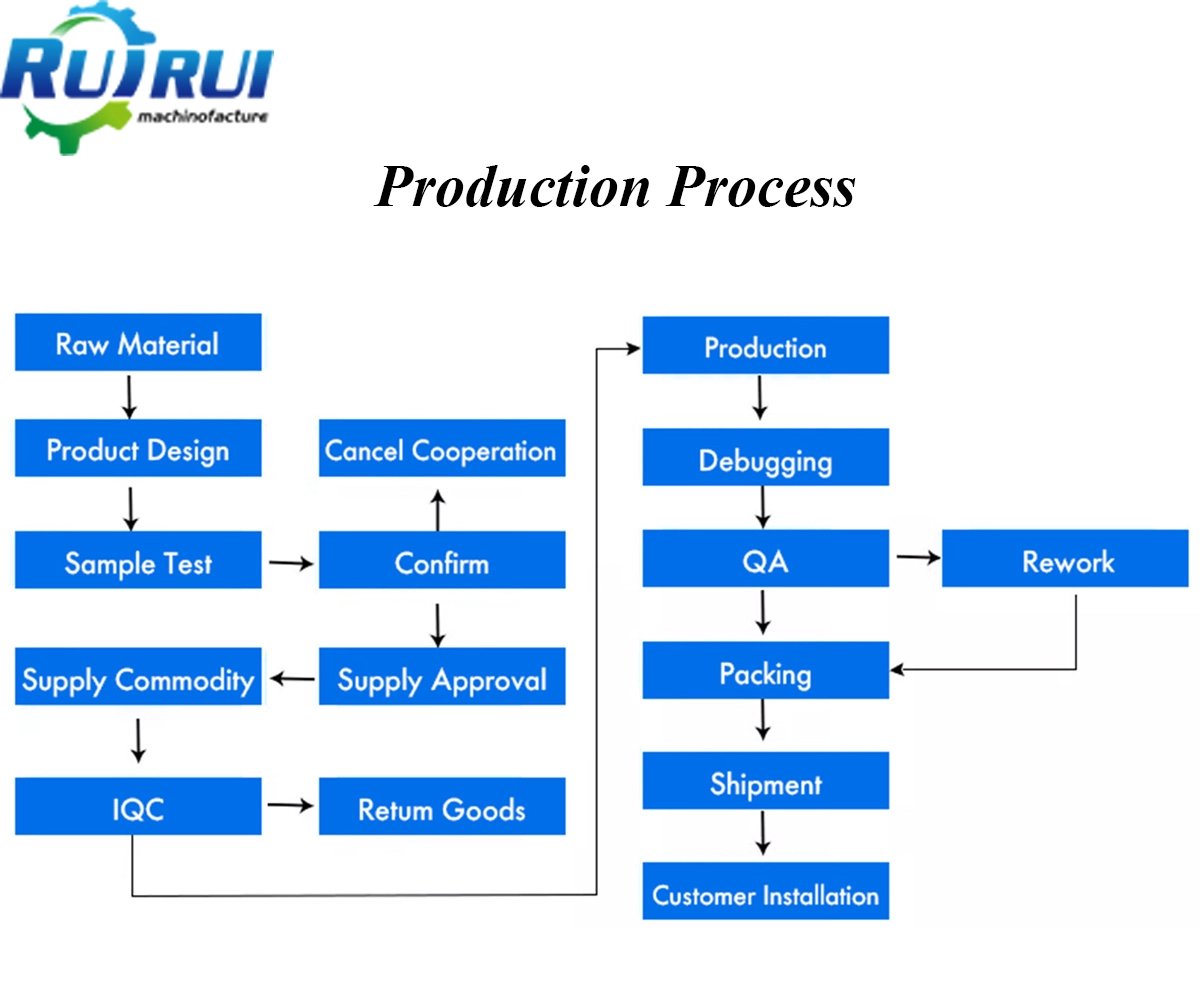

One-Stop Production

We handle everything from raw material procurement through finished product testing. Our complete quality control system ensures consistent performance across every batch.

Custom Solutions Available

Our dedicated R&D team provides OEM/ODM services. We optimize designs for manufacturability and offer custom dimensions to meet your specific requirements.

Global Shipping Capability

Located near Qingdao Port, we offer flexible shipping terms including EXW, FOB, and DDP. Your orders reach you efficiently worldwide.

Quality Assurance Process

Every batch of our products undergoes rigorous testing:

1. Material Verification: Chemical composition analysis ensures grade compliance

2. Dimensional Inspection: CMM and optical comparators verify critical measurements

3. Mechanical Testing: Tensile and yield strength validation

4. Surface Quality Check: Passivation layer verification for corrosion resistance

5. Documentation: Complete material certificates and test reports included

Why Choose Ruirui for Your Fastener Needs?

Proven Track Record

Since 2008, we've manufactured precision fasteners for automotive, aerospace, and industrial clients worldwide. Our 17+ years of OEM/ODM experience means you get solutions that work.

Advanced Equipment

Our 20+ CNC machines handle complex geometries with Swiss-type precision. Multi-axis capabilities ensure consistent quality even for intricate square U-bolt configurations.

Engineering Support

Need design assistance? Our team provides free DFM analysis and recommendations to optimize your fastener selection for maximum performance and cost-effectiveness.

Flexible Production

Whether you need prototypes in 1-2 weeks or mass production in 4-7 weeks, our 24/7 production capacity with three-shift operation meets your timeline requirements.

Order Information

Ready to upgrade your square-profile applications with premium products? We make ordering simple:

· Minimum Order: 1,000 pieces

· Quote Timeline: 48 hours after receiving your specifications

· Prototyping: Available with no minimum order quantity

· Custom Dimensions: Engineered to your exact requirements

Contact Us

Get your quote today for Stainless Steel Square U Bolts and experience the Ruirui difference: kshdhardware@qdkshd.com.

Send Inquiry

You may like