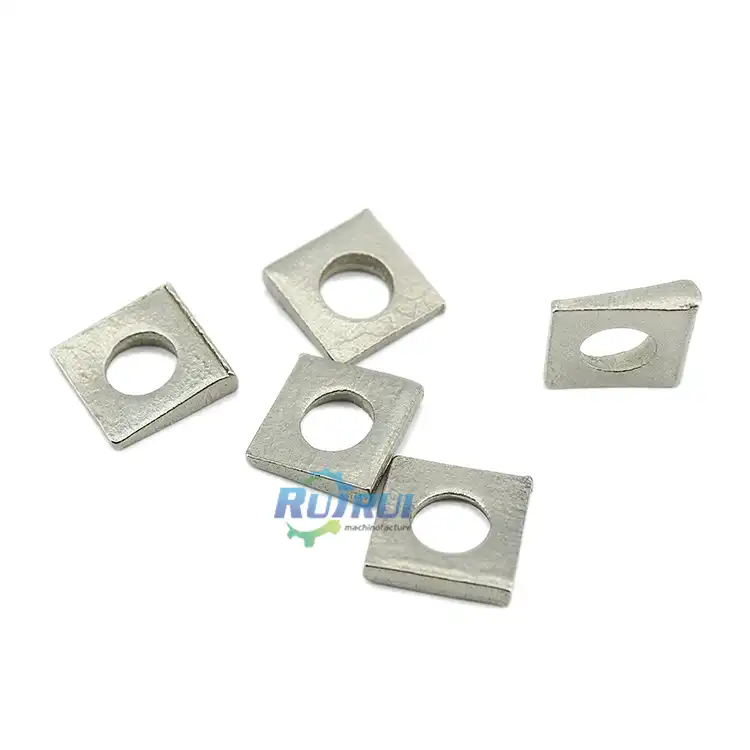

Metric Hardened Beveled Washers

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Product Details

Our Metric Hardened Beveled Washers are not your standard washers. They are precision-engineered components designed to solve a critical problem: joint loosening under high vibration and dynamic loads.

The unique beveled (conical) design allows the washer to bite into both the bearing surface and the nut or bolt head. When tightened, this creates a powerful locking action that resists rotation and maintains clamp load far more effectively than a flat washer. Manufactured from high-carbon steel and through-hardened, these washers offer superior strength and durability, preventing brinelling and surface deformation.

Product Specifications: Precision You Can Trust

We understand that your projects demand exact specifications. Our washers are produced to stringent quality standards, ensuring consistency and reliability in every batch.

| Specification | Details |

|---|---|

| Standard | Metric (DIN 6797) |

| Material | High-Carbon Steel (Grade 65Mn / 1050) |

| Hardness | 44-50 HRC (Hardened & Tempered) |

| Surface Treatment | Plain, Zinc Plated, Galvanized, or Phosphated (Custom options available) |

| Size Range | M5 to M36 (Larger sizes available upon request) |

| Quality Assurance | ISO 9001, RoHS Compliant |

Product Applications: Where Reliability is Non-Negotiable

Our hardened beveled washers are critical components across a wide range of industries, particularly where safety and performance are paramount. They are the ideal choice for:

-

Heavy Machinery & Equipment: Excavators, bulldozers, and agricultural machinery subject to constant vibration.

-

Automotive & Aviation: Critical assemblies in engines, chassis, and landing gear where failure is not an option.

-

Structural Steel & Construction: Securing bolts in steel frameworks, bridges, and seismic bracing.

-

Electronics & Home Appliances: High-end applications requiring secure, long-lasting fastening in compact spaces.

-

OEM Manufacturing: As a reliable component in your original equipment, ensuring your product's integrity.

Product Advantages: Why Our Washers Outperform the Rest

Choosing RUIRUI’s washers means investing in peace of mind and long-term value for your supply chain.

-

Superior Vibration Resistance: The beveled design provides a permanent locking force, eliminating the need for secondary locking devices.

-

Enhanced Joint Integrity: Prevents bolt loosening, protecting your equipment from damage and downtime.

-

High Hardness & Strength: The hardening process ensures the washer does not deform under high pressure, maintaining clamp load.

-

Reduced Maintenance Costs: By securing joints effectively, you minimize the need for re-tightening and repairs.

-

Cost-Effective Solution: A simple, single-component solution that outperforms more complex and expensive locking systems.

Why Choose RUIRUI MACHINERY as Your Supplier?

As a professional manufacturer and supplier, we go beyond just selling a product. We offer a partnership built on reliability and expertise.

-

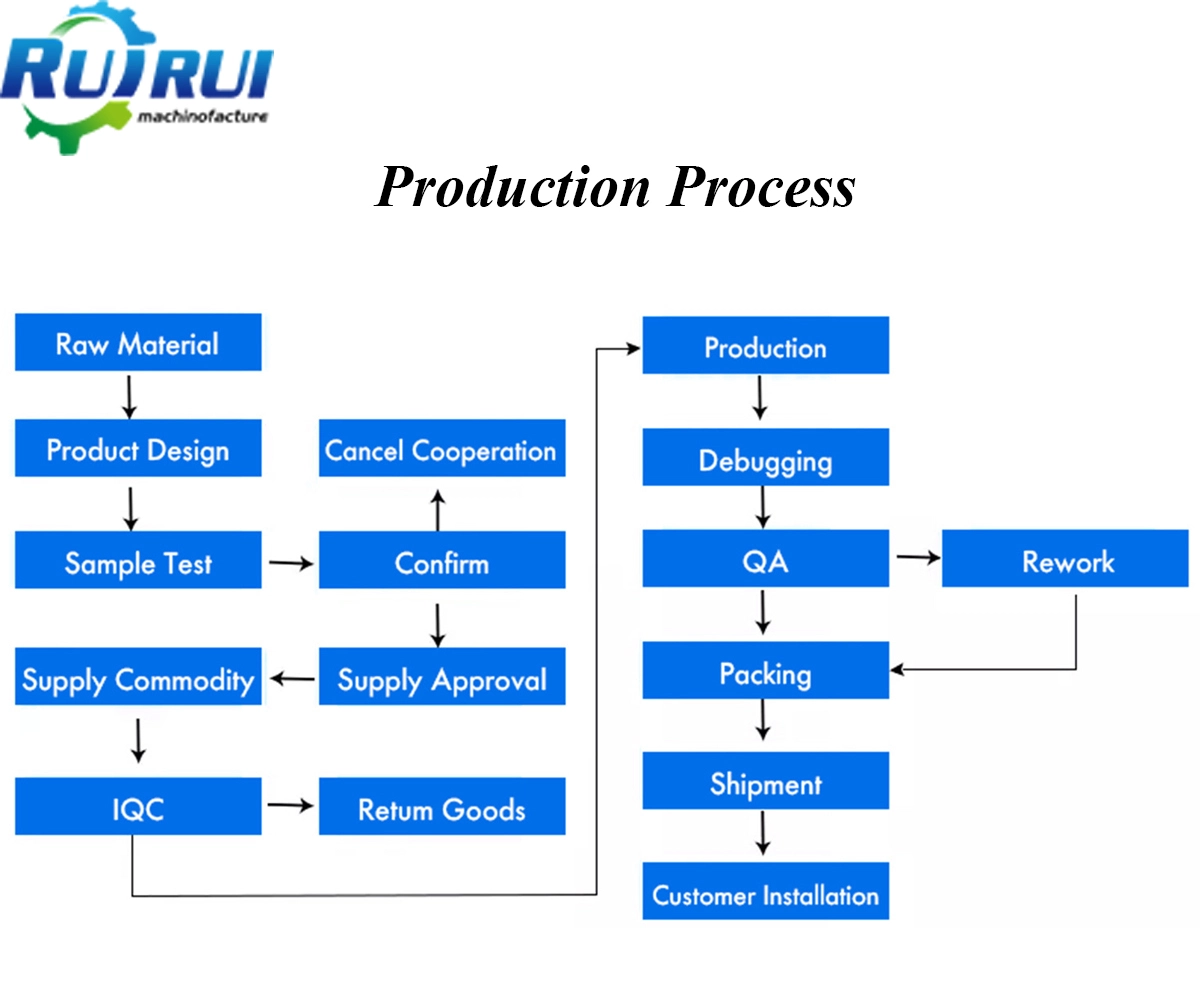

Source Factory Advantage: We control the entire manufacturing process, from raw material to finished product, ensuring quality and short delivery times.

-

Efficient R&D Team: Have a unique requirement? Our experienced technical team can collaborate with you on material or design modifications.

-

OEM Support Welcomed: We provide comprehensive OEM support, including custom packaging and branding to meet your specific needs.

-

Stable Supply Chain: Our robust manufacturing capabilities and inventory management guarantee a stable supply, even for large-volume orders.

-

Stringent Quality Control: Every batch of our hardened beveled spring washers undergoes rigorous inspection to meet international standards.

Our Services: A Partnership for Your Success

We are committed to making your procurement process seamless and efficient.

-

Bulk Procurement & Long-Term Agreements: Competitive pricing for large-volume orders and the security of long-term supply contracts.

-

Expert Technical Support: Our engineers are available to assist with application questions and specification guidance.

-

Global Logistics: We are experienced in shipping to industrial hubs worldwide, including the Yangtze River Delta, Pearl River Delta, Europe, and North America.

-

Professional Packaging: Products are carefully packaged to prevent damage during transit, ensuring they arrive in perfect condition.

Product Customization: Tailored to Your Blueprint

Your unique applications demand unique solutions. We specialize in customizing our metric hardened beveled washers to your exact specifications.

-

Non-Standard Sizes: Need a diameter or thickness not listed in our standard range? We can produce it.

-

Special Materials: Require stainless steel (e.g., 304 or 316) or other alloys for corrosive environments? Just ask.

-

Custom Surface Treatments: We can apply specific coatings to meet your environmental or aesthetic requirements.

-

Modified Designs: Slight alterations to the bevel angle or internal/external tooth profiles can be accommodated.

Contact us with your drawings or samples for a fast and accurate quotation.

FAQ

Q1: What is the primary difference between a beveled washer and a standard flat washer?

A: A standard flat washer is primarily used to distribute load. A beveled washer is a locking washer; its conical shape creates tension and bites into the mating surfaces to prevent the nut or bolt from loosening under vibration.

Q2: Are your hardened beveled washers reusable?

A: For critical applications, it is generally recommended to use new washers. While they can often be reused in non-critical situations, the locking force and hardness may be slightly reduced after initial compression.

Q3: Can you provide washers with specific certifications?

A: Yes. As an ISO 9001 certified manufacturer, we can provide material certifications and are able to support other industry-specific quality audits as required.

Q4: What is your typical lead time for bulk orders?

A: Due to our efficient manufacturing capabilities, our lead times are highly competitive. For standard items, we can often ship within 7-10 days. For custom orders, the lead time will be confirmed based on the specifications and quantity.

Q5: How do I request a quote or place a sample order?

A: Simply reach out to our sales team at [kshdhardware@qdkshd.com] with your specifications, required quantities, and any applicable drawings. We will respond with a comprehensive quote promptly. Sample orders are welcome so you can verify quality before committing to a larger purchase.

Ready to Secure Your Assemblies with Confidence?

Don't let vibration and dynamic loads compromise your product's integrity. Partner with a supplier who understands the critical nature of your components.

Contact RUIRUI MACHINERY today to request your competitive quote, discuss custom specifications, or place a sample order.

Email: kshdhardware@qdkshd.com

Send Inquiry

You may like