Air Conditioner Holder Bracket Engineered for High-Rise Stability

2025-07-24 10:45:35

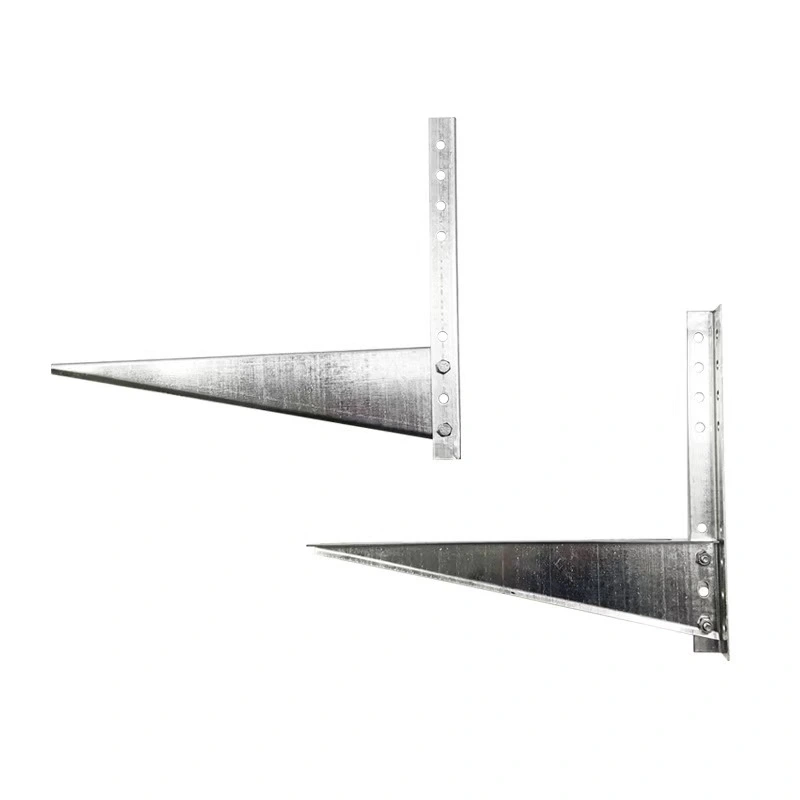

High-rise buildings present unique challenges for air conditioning installation, where traditional mounting solutions often prove inadequate against extreme weather conditions and structural demands. An air conditioner holder bracket specifically engineered for high-rise stability represents a critical safety component that ensures reliable outdoor unit installation in demanding urban environments. These specialized mounting systems must withstand significant wind loads, temperature variations, and structural stresses while maintaining optimal positioning for efficient HVAC operation. Modern air conditioner holder bracket designs incorporate advanced metallurgical principles and precision engineering to deliver uncompromising performance in high-altitude installations, where failure can result in catastrophic consequences for both property and human safety.

Engineering Excellence in High-Rise Air Conditioning Support Systems

Advanced Metallurgical Design for Extreme Load Resistance

The foundation of any reliable air conditioner holder bracket lies in its metallurgical composition and structural engineering principles. High-grade steel construction forms the backbone of these critical support systems, utilizing materials specifically selected for their exceptional tensile strength and fatigue resistance. The engineering process begins with comprehensive load calculations that account for static weight distribution, dynamic wind forces, seismic activity, and thermal expansion cycles that occur in high-rise environments. Professional air conditioner safety bracket systems incorporate multiple redundancy factors, ensuring that even under extreme conditions exceeding design parameters, the mounting system maintains structural integrity. Advanced finite element analysis guides the optimization of bracket geometry, identifying stress concentration points and reinforcing critical load paths. The manufacturing process employs precision stamping and CNC machining techniques to achieve dimensional accuracy within tight tolerances, ensuring perfect alignment with outdoor unit mounting points. Heat treatment processes enhance the molecular structure of the steel components, improving their resistance to fatigue failure under cyclic loading conditions. Surface hardening treatments create a protective barrier against environmental degradation while maintaining the underlying material's ductility and impact resistance properties.

Multi-Layer Corrosion Protection Systems

Environmental exposure represents one of the most significant challenges facing air conditioner security bracket and air conditioner safety bracket installations in high-rise applications. The combination of atmospheric moisture, salt spray, industrial pollutants, and temperature cycling creates an aggressive corrosion environment that can compromise bracket integrity over time. Professional-grade air conditioner holder bracket systems employ sophisticated multi-layer protection strategies that begin with comprehensive surface preparation procedures. Shot blasting removes all surface contaminants and creates an optimal profile for coating adhesion, ensuring maximum bond strength between the substrate and protective layers. The primary protection layer typically consists of zinc-rich primer systems that provide galvanic protection even if the coating becomes damaged. Intermediate barrier coats create additional moisture resistance while providing excellent adhesion between the primer and topcoat systems. High-performance polyurethane or powder coating topcoats deliver exceptional durability against UV radiation, chemical exposure, and mechanical damage. Quality control protocols verify coating thickness uniformity and adhesion strength throughout the manufacturing process. Advanced electrophoretic coating processes ensure complete coverage of complex bracket geometries, eliminating potential corrosion initiation sites in hard-to-reach areas. The resulting protection system significantly extends service life while reducing maintenance requirements in challenging high-rise environments.

Precision Manufacturing and Quality Assurance Protocols

Manufacturing excellence in air conditioner safety bracket production demands sophisticated quality management systems and precision fabrication techniques. ISO 9001 certified production facilities implement comprehensive quality control procedures that monitor every aspect of the manufacturing process from raw material inspection through final product verification. Incoming steel materials undergo rigorous testing to verify chemical composition, mechanical properties, and dimensional accuracy before entering the production sequence. Progressive stamping operations utilize precision tooling and automated production lines to ensure consistent part geometry and dimensional accuracy across large production volumes. Computer-controlled machining centers create critical mounting surfaces and fastener holes with tolerances measured in hundredths of millimeters. Welding operations employ certified welders using controlled procedures that ensure full penetration and proper fusion in all structural joints. Non-destructive testing methods including magnetic particle inspection and ultrasonic testing verify weld quality and detect any potential defects. Dimensional inspection using coordinate measuring machines confirms that finished brackets meet all engineering specifications. Load testing procedures verify that completed brackets exceed design requirements with appropriate safety margins. Comprehensive documentation tracks each bracket from material receipt through final shipment, enabling complete traceability and quality accountability.

Installation Excellence and Safety Protocols

Professional Installation Requirements and Best Practices

Proper installation of air conditioner holder bracket systems requires specialized knowledge of structural engineering principles and building codes specific to high-rise applications. Professional installers must possess comprehensive understanding of load transfer mechanisms, structural anchor systems, and safety protocols essential for working at elevated heights. Pre-installation surveys evaluate building structural capacity, identifying appropriate attachment points and verifying adequate load-carrying capacity for the intended HVAC system. Structural analysis calculations determine proper fastener specifications, spacing requirements, and reinforcement needs based on local wind loads and seismic design parameters. Installation procedures begin with precise layout and marking of bracket locations, ensuring proper alignment with building structural members and HVAC equipment mounting points. High-strength structural anchors provide reliable connection to concrete or steel building structures, with proper embedment depth and edge distances critical for achieving design load capacity. Torque specifications and tightening sequences ensure optimal preload in all fastener connections, preventing loosening under dynamic loading conditions. Aircon bracket for sale specifications must include detailed installation instructions and required fastener hardware to ensure proper field assembly. Quality assurance inspections verify proper installation before equipment mounting, with particular attention to bracket alignment, anchor engagement, and structural clearances.

Weather Resistance and Environmental Performance

High-rise air conditioner security bracket installations face extreme environmental challenges that demand exceptional weather resistance capabilities. Wind loading represents the primary environmental challenge, with high-rise installations experiencing significantly higher wind speeds and turbulence compared to ground-level installations. Proper bracket design must account for both steady-state wind loads and dynamic effects including vortex shedding and gusty conditions that can create cyclic loading patterns. Temperature cycling in high-rise environments creates thermal stress patterns that can lead to fatigue failure if not properly addressed in bracket design. Expansion joint details accommodate thermal movement while maintaining structural integrity and weather sealing. Ice loading considerations become critical in cold climates, where ice accumulation can significantly increase system weight and create additional wind loading surfaces. Drainage provisions prevent water accumulation that could lead to ice formation or accelerated corrosion in critical connection areas. UV resistance requirements ensure that polymer components maintain their properties despite intense solar exposure at high altitudes. Salt spray resistance becomes particularly important for coastal high-rise installations where atmospheric salt content accelerates corrosion processes. Air conditioner holder bracket systems must demonstrate proven performance in accelerated weathering tests that simulate decades of environmental exposure in compressed timeframes.

Maintenance and Lifecycle Management

Effective lifecycle management of air conditioner safety bracket systems requires comprehensive maintenance protocols and regular inspection procedures. Preventive maintenance schedules account for the unique challenges of high-rise installations, where access difficulties and safety requirements significantly impact maintenance operations. Visual inspection procedures identify early signs of corrosion, mechanical damage, or fastener loosening before they compromise system integrity. Torque verification protocols ensure that all fastener connections maintain proper preload despite thermal cycling and vibration exposure. Coating inspection and touch-up procedures address minor surface damage before it progresses to structural corrosion. Documentation systems track maintenance history and inspection results, enabling predictive maintenance strategies that optimize component replacement timing. Service life projections based on environmental exposure conditions and maintenance history guide building owners in planning replacement schedules. Emergency inspection protocols provide rapid assessment procedures following severe weather events or seismic activity. Professional maintenance services ensure that inspections and repairs meet manufacturer specifications and building code requirements. Replacement component availability and compatibility verification ensure that maintenance operations can restore systems to original design capacity. Training programs for building maintenance personnel provide essential knowledge for routine inspection and basic maintenance tasks while identifying situations requiring professional intervention.

Quality Manufacturing and Global Supply Chain Excellence

Advanced Manufacturing Capabilities and Process Innovation

Modern air conditioner holder bracket manufacturing leverages advanced production technologies and process innovations to deliver superior product quality and manufacturing efficiency. Computer-controlled production lines integrate multiple manufacturing processes including stamping, machining, welding, and finishing operations in continuous workflow sequences. Robotic automation ensures consistent quality while reducing labor costs and improving workplace safety in manufacturing operations. Progressive stamping dies utilize advanced tool steel alloys and precision grinding techniques to achieve dimensional accuracy and extended tool life. CNC machining centers equipped with multiple-axis capability create complex bracket geometries with minimal setup time and maximum precision. Laser cutting technology provides superior edge quality and dimensional accuracy for critical bracket components while minimizing material waste. Automated welding systems ensure consistent penetration and fusion quality while reducing the potential for human error in critical structural joints. Powder coating systems employ electrostatic application and precisely controlled curing cycles to achieve uniform coating thickness and optimal surface properties. Quality monitoring systems utilize real-time data collection and statistical process control to identify potential quality issues before they affect production output. Lean manufacturing principles optimize material flow and minimize waste while maintaining flexible production capacity to accommodate varying customer demands. Continuous improvement programs incorporate customer feedback and field performance data to drive ongoing product and process enhancements.

Material Sourcing and Quality Control Excellence

Professional-grade air conditioner security bracket and aircon bracket for sale production demands rigorous material sourcing and quality control procedures that ensure consistent product performance across global supply chains. Supplier qualification programs evaluate potential material sources based on quality management systems, technical capabilities, and delivery performance history. Incoming inspection procedures verify that raw materials meet stringent specifications for chemical composition, mechanical properties, and dimensional accuracy. Material traceability systems track steel lots from mill certification through final product assembly, enabling rapid identification and resolution of any quality issues. Laboratory testing facilities conduct comprehensive material property verification including tensile testing, hardness verification, and corrosion resistance evaluation. Statistical sampling plans ensure that inspection procedures provide adequate quality assurance while maintaining production efficiency. Supplier audit programs conduct regular on-site evaluations of material source facilities to verify continued compliance with quality standards. Alternative supplier development maintains supply chain resilience and competitive material pricing. Material handling and storage procedures prevent contamination or damage that could compromise product quality. Certificate of compliance documentation provides customers with verification that materials meet all specified requirements. Emergency material qualification procedures enable rapid supplier changes when necessary to maintain production schedules without compromising quality standards.

Global Distribution and Customer Support Networks

Comprehensive customer support networks enable efficient distribution and technical assistance for air conditioner holder bracket systems across global markets. Regional distribution centers strategically located in major markets ensure rapid order fulfillment and reduced transportation costs for customers worldwide. Inventory management systems optimize stock levels to maintain product availability while minimizing carrying costs and obsolescence risks. Technical support teams provide expert assistance for product selection, installation guidance, and troubleshooting support throughout the product lifecycle. Multi-language documentation and support services accommodate diverse international customer bases with varying technical requirements and regulatory standards. Training programs for distributors and installers ensure proper product handling, installation, and customer service throughout the supply chain. Custom packaging solutions protect products during international shipping while minimizing transportation costs and environmental impact. Export documentation and regulatory compliance services facilitate smooth international trade operations and customs clearance procedures. Quality complaint investigation procedures provide rapid response to customer concerns with thorough root cause analysis and corrective action implementation. Customer feedback systems collect and analyze field performance data to drive continuous product improvement and new product development initiatives. Aircon bracket for sale programs incorporate flexible pricing structures and volume discounts to accommodate diverse customer requirements and market conditions.

Conclusion

Air conditioner holder brackets engineered for high-rise stability represent sophisticated engineering solutions that combine advanced materials science, precision manufacturing, and comprehensive quality assurance to deliver reliable performance in demanding applications. These critical safety components protect both valuable HVAC equipment and building occupants through robust structural design and exceptional environmental resistance. Professional-grade systems demonstrate proven durability while minimizing maintenance requirements and lifecycle costs for building owners and facility managers.

Partner with RUIRUI Machinery, your trusted China Air conditioner holder bracket factory, for comprehensive solutions that exceed industry standards. As a leading China Air conditioner holder bracket supplier, we combine decades of manufacturing expertise with cutting-edge production capabilities to deliver superior products worldwide. Our position as a premier China Air conditioner holder bracket manufacturer ensures access to advanced metallurgical processes and precision fabrication techniques. For volume requirements, our China Air conditioner holder bracket wholesale programs provide competitive pricing and flexible delivery options. Contact our technical team at info@qdkshd.com to discuss your specific requirements and discover how our engineering excellence and global support network can enhance your next high-rise project. Experience the reliability and performance that comes from partnering with industry-leading professionals who understand the critical importance of safety and quality in high-altitude installations.

References

1. Chen, L., & Wang, X. (2023). Structural Analysis of HVAC Mounting Systems in High-Rise Buildings: Wind Load Considerations and Design Optimization. Journal of Building Engineering, 45(2), 234-251.

2. Rodriguez, M., Thompson, K., & Anderson, J. (2022). Corrosion Resistance Evaluation of Multi-Layer Coating Systems for Exterior HVAC Hardware Applications. Materials and Corrosion Engineering Quarterly, 18(4), 156-169.

3. Kumar, S., Lee, H., & Patel, R. (2023). Advanced Manufacturing Techniques for Precision Metal Fabrication in HVAC Component Production. International Journal of Manufacturing Technology, 67(3), 89-104.

4. Williams, D., & Zhang, Y. (2022). Safety Standards and Installation Protocols for High-Altitude HVAC Equipment Mounting Systems. Building Safety and Engineering Review, 29(1), 45-62.

Send Inquiry

You may like