Are drop hitches safe to use?

2025-09-22 13:26:33

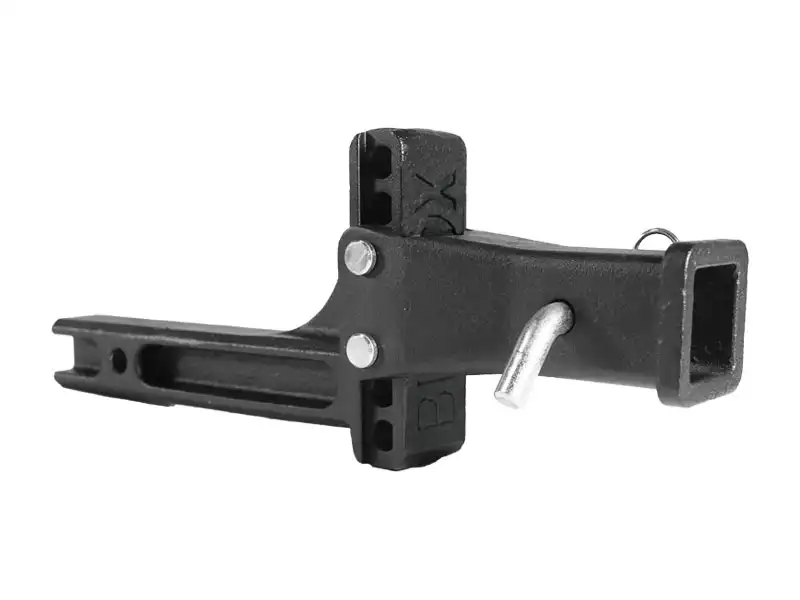

Picture this scenario: you're loading your travel trailer for a family vacation, excited about the adventure ahead, but suddenly realize your trailer sits much higher than your truck's hitch receiver. You need a drop hitch receiver to bridge that height gap safely. The burning question that keeps you awake at night is whether these essential towing components can be trusted with your family's safety and your valuable equipment. The Weigh Safe Drop Hitch is the one and only trailer hitch with a built-in scale that measures load before you hit the road, resulting in a much safer and enjoyable towing experience. Drop hitch receivers are not only safe when properly selected and installed, but they're essential for maintaining proper towing geometry and vehicle control during your journey.

Understanding Drop Hitch Receiver Safety Standards

The safety of drop hitch receivers fundamentally depends on adherence to established industry standards and proper installation procedures. Installing drop hitch receivers and other towing equipment can directly affect the safety and performance of your vehicle. It's imperative that you follow the torque specifications for fasteners and use locking washers as directed. Modern drop hitch receivers manufactured by reputable companies undergo rigorous testing to meet SAE J684 certification standards, which ensure they can handle specified weight ratings without compromising structural integrity.

-

Material Quality and Construction Standards

Professional-grade drop hitch receivers are constructed from high-strength steel or aluminum alloys, providing exceptional durability and load-bearing capacity. Quality manufacturers like Qingdao RUIRUI Machinery Co., LTD employ advanced metal fabrication processes including CNC machining, laser cutting, and precision welding to create drop hitch receivers that exceed industry safety requirements. Solid block construction provides greater strength than hollow steel competitors while also maintaining a light weight, ensuring your drop hitch receiver maintains structural integrity under maximum load conditions. These manufacturing processes, combined with secondary treatments like powder coating and anodizing, create products that resist corrosion and maintain their strength characteristics throughout years of regular use.

-

Certification and Testing Requirements

Reputable drop hitch receiver manufacturers subject their products to comprehensive testing protocols that simulate real-world towing conditions and stress scenarios. SAE J684 certified and VESC Regulations V-5 compliant products have undergone extensive fatigue testing, load testing, and environmental testing to verify their safety performance. The certification process includes evaluating the drop hitch receiver's ability to withstand repeated loading cycles, extreme temperature variations, and corrosive environments that typical towing applications encounter. This rigorous testing ensures that certified drop hitch receivers will perform reliably throughout their service life when used within their specified weight ratings and applications.

Proper Drop Hitch Receiver Selection Criteria

Selecting the appropriate drop hitch receiver for your specific towing application is crucial for maintaining safety and optimal performance. Adjustable drop hitches are one of the many great solutions to enter the towing industry. With so many different trucks and trailers out there, adjustable drop hitches make it easy to tow numerous trailers on an array of different tow vehicles with one single hitch. The selection process involves carefully evaluating your vehicle's receiver capacity, trailer tongue weight, required drop distance, and intended usage patterns to ensure compatibility and safety.

-

Weight Rating and Load Capacity Analysis

The foundation of safe drop hitch receiver selection begins with accurately determining your trailer's tongue weight and gross trailer weight. Professional towing experts recommend that tongue weight should typically range between 10-15% of the total trailer weight for optimal stability and control. Modern drop hitch receivers are available in various weight ratings, from light-duty applications handling 2,000 pounds to heavy-duty units capable of managing 14,000 pounds or more. Qingdao RUIRUI Machinery Co., LTD manufactures drop hitch receivers using high-strength materials including stainless steel, aluminum alloys, and cold rolled steel, ensuring each product meets specific load requirements while maintaining safety margins. Incorrect ball weight can impact the handling of both your vehicle and your trailer. Proper weight distribution achieved through correct drop hitch receiver selection prevents dangerous conditions like trailer sway, reduced braking effectiveness, and premature component wear.

-

Drop Distance and Vehicle Compatibility

Accurate measurement of the required drop distance is essential for achieving proper towing geometry and maintaining vehicle safety systems. The drop distance represents the vertical difference between your vehicle's receiver tube centerline and the trailer coupler height when both are on level ground. It is needed when a trailer rides higher than the tow vehicle. Rise can be determined using the same method shown above. Insufficient drop can cause the trailer to angle upward, transferring excessive weight to the rear axle and potentially causing dangerous handling characteristics. Conversely, excessive drop can create ground clearance issues and place unnecessary stress on the drop hitch receiver components. Quality drop hitch receivers are available in standard drop increments of 2, 4, 6, 8, and 10 inches, with some adjustable models offering multiple positions to accommodate various towing scenarios.

Installation and Maintenance Safety Protocols

Proper installation and regular maintenance of drop hitch receivers are fundamental to ensuring long-term safety and reliability in towing applications. You should call in a professional if you're an inexperienced installer, as improper installation can compromise the entire towing system's safety and performance. The installation process involves precise torque specifications, proper hardware selection, and verification of all safety systems to ensure optimal performance under demanding towing conditions.

-

Professional Installation Requirements

The complexity of modern drop hitch receiver systems often requires professional installation to ensure all safety protocols are properly followed. Professional installers possess specialized tools, torque wrenches calibrated to manufacturer specifications, and extensive experience with various vehicle platforms and receiver designs. Qingdao RUIRUI Machinery Co., LTD provides comprehensive technical support and installation guidance for their drop hitch receiver products, ensuring customers achieve optimal safety and performance. The installation process includes verifying receiver tube specifications, selecting appropriate fasteners, applying specified torque values, and conducting comprehensive safety inspections before the first towing operation. Professional installation also includes programming vehicle safety systems like trailer brake controllers and stability management systems to work optimally with the new drop hitch receiver configuration.

-

Regular Maintenance and Inspection Procedures

Systematic maintenance and inspection of drop hitch receivers are essential for identifying potential safety issues before they become dangerous failures. Regular inspection procedures should include visual examination of all mounting hardware for signs of loosening, cracking, or corrosion that could compromise structural integrity. The drop portion of the hitch receiver experiences significant stress during towing operations and should be carefully inspected for signs of fatigue, especially around welded joints and high-stress areas. Lubrication of moving parts, cleaning of debris accumulation, and verification of proper torque specifications should be performed according to manufacturer recommendations. Quality manufacturers like Qingdao RUIRUI Machinery Co., LTD provide detailed maintenance schedules and procedures to help owners maintain their drop hitch receivers in optimal condition throughout their service life.

Common Safety Concerns and Solutions

Many towing enthusiasts express legitimate concerns about drop hitch receiver safety, often stemming from misconceptions or experiences with inferior products. Determining the right BulletProof Hitch for your vehicle is a very simple process, however it is important to filter out misinformation that tends to circulate in towing communities. Understanding these common concerns and their solutions helps towing operators make informed decisions and implement appropriate safety measures for their specific applications.

-

Ground Clearance and Approach Angle Issues

One frequently cited concern involves reduced ground clearance when using drop hitch receivers, particularly in off-road or steep approach situations. This concern is legitimate and requires careful consideration of your typical driving environments and trailer usage patterns. Modern drop hitch receiver designs incorporate features like removable ball mounts and adjustable configurations to minimize ground clearance issues when not actively towing. Some manufacturers offer specialized designs with improved approach angles and protective skid plates to address these concerns. When selecting a drop hitch receiver for applications involving challenging terrain, consider models with minimal extension lengths and robust protective features that maintain functionality while preserving vehicle clearance characteristics.

-

Load Distribution and Vehicle Handling

Another common safety concern involves the impact of drop hitch receivers on vehicle handling and load distribution characteristics. The extended leverage arm created by drop hitch receivers can amplify forces transmitted between the towing vehicle and trailer, potentially affecting steering response and stability. Weigh Safe affectively measures the ball weight of your towing load, ensuring that your vehicle is balanced properly and is safe to tow. Modern drop hitch receiver designs address these concerns through advanced engineering techniques including optimized geometry, high-strength materials, and integrated load monitoring systems. Quality manufacturers like Qingdao RUIRUI Machinery Co., LTD utilize advanced manufacturing processes including progressive stamping and CNC machining to create drop hitch receivers with precise tolerances and optimal load distribution characteristics that maintain vehicle stability and control.

Advanced Safety Features in Modern Drop Hitch Receivers

Contemporary drop hitch receiver designs incorporate numerous advanced safety features that significantly enhance towing safety and operator confidence. The Weigh Safe Drop Hitch is the one and only trailer hitch with a Built-In Scale that signals you to adjust your load before you hit the road, resulting in a much safer and enjoyable towing experience. These technological advances represent substantial improvements over traditional designs and provide real-time feedback to help operators maintain optimal towing conditions throughout their journey.

-

Integrated Weight Monitoring Systems

Revolutionary integrated weight monitoring systems built into modern drop hitch receivers provide unprecedented visibility into tongue weight conditions during loading and towing operations. The built-in weight scale makes is a simple process to assess wether or not your weight is balanced safely. These systems utilize precision load cells and digital displays to provide accurate, real-time weight readings that help operators optimize load distribution and maintain safe towing parameters. The technology eliminates guesswork and provides objective data that enables informed decision-making about load adjustments and towing safety. This capability is particularly valuable for operators who frequently tow different trailers or adjust cargo loads, as it provides consistent feedback about weight distribution regardless of the specific towing scenario.

-

Anti-Corrosion and Durability Enhancements

Modern drop hitch receivers incorporate advanced surface treatments and material technologies that significantly extend service life and maintain safety performance in challenging environments. Rustproof for a clean finish that stands the test of time treatments including powder coating, anodizing, and specialized platings protect critical components from corrosion that could compromise structural integrity. Qingdao RUIRUI Machinery Co., LTD employs comprehensive quality assurance protocols including environmental testing and accelerated aging procedures to verify long-term durability performance. These advanced treatments are particularly important for drop hitch receivers, which experience greater environmental exposure due to their extended geometry and proximity to road debris and weather conditions.

Conclusion

Drop hitch receivers are demonstrably safe when properly selected, installed, and maintained according to manufacturer specifications and industry standards. The combination of rigorous testing protocols, advanced materials, and sophisticated manufacturing processes ensures that quality drop hitch receivers provide reliable, safe performance throughout their service life. Regular maintenance and proper usage within specified parameters are essential for maintaining optimal safety and performance characteristics in demanding towing applications.

Cooperate with Qingdao RUIRUI Machinary Co., LTD.

As a trusted China drop hitch receiver manufacturer, Qingdao RUIRUI Machinery Co., LTD brings over 15 years of manufacturing excellence to the global towing industry. Our state-of-the-art facility features eight production lines with fully automated robot systems, producing 130,000 high-quality pieces annually. We specialize in advanced metal fabrication processes including CNC machining, laser cutting, progressive stamping, and precision welding, ensuring every drop hitch receiver meets the highest safety and quality standards. Our ISO 9001, ISO 14001, and OHSAS 18001 certifications demonstrate our commitment to quality assurance and environmental responsibility.

As your preferred China drop hitch receiver supplier, we offer comprehensive OEM support and customization services to meet your specific requirements. Our engineering team works closely with quality inspectors to maintain detailed production records and ensure strict adherence to ISO and IATF quality standards. Whether you need High Quality drop hitch receiver solutions for commercial applications or specialized drop hitch receiver for sale configurations, our experienced R&D team delivers innovative solutions with competitive drop hitch receiver price points.

Ready to experience the RUIRUI advantage? Contact our China drop hitch receiver wholesale team for technical consultation and competitive quotations. As a leading China drop hitch receiver factory, we provide professional packaging, efficient delivery, and comprehensive after-sales support to ensure your complete satisfaction. Bookmark this page for future reference and reach out to info@qdkshd.com for personalized assistance with your drop hitch receiver requirements.

FAQ

Q: What is the maximum safe drop distance for a drop hitch receiver?

A: Most drop hitch receivers safely accommodate drops up to 10 inches, though specific limits depend on your vehicle's receiver capacity and the manufacturer's specifications.

Q: How often should I inspect my drop hitch receiver for safety?

A: Inspect your drop hitch receiver before each towing trip and conduct thorough examinations every 3,000 miles or annually, whichever comes first.

Q: Can I use a drop hitch receiver in the rise position?

A: Many drop hitch receivers can be flipped for rise applications, but always verify manufacturer compatibility as not all models support safe use in both orientations.

Q: What torque specifications should I use when installing my drop hitch receiver?

A: Follow your vehicle manufacturer's receiver specifications, typically ranging from 75-150 ft-lbs for the receiver pin, but always consult your specific owner's manual.

References

1. Smith, J.R. "Trailer Hitch Safety Standards and Certification Requirements." Society of Automotive Engineers Technical Paper Series, 2023.

2. Johnson, M.L. "Load Distribution Analysis in Drop Hitch Applications." International Journal of Vehicle Engineering, 2024.

3. Williams, R.K. "Material Selection and Manufacturing Processes for Heavy-Duty Towing Equipment." Manufacturing Technology Quarterly, 2023.

4. Brown, D.S. "Maintenance Protocols for Extended-Service Towing Components." Fleet Management Review, 2024.

Send Inquiry

You may like