Beyond the Hitch: How Trailer Safety Chains Act as Your Final Safety Net

2025-09-30 11:11:52

Picture this: You're driving down a busy highway when suddenly your trailer hitch fails, and your valuable cargo begins to sway dangerously behind you. Without proper trailer safety chains, this nightmare scenario could result in catastrophic accidents, property damage, and even loss of life. In the unfortunate event that the hitch fails, safety chains act as a safety net, keeping the trailer from completely detaching, making them your absolute last line of defense on the road. This comprehensive guide reveals how trailer safety chains function as the critical backup system that every responsible trailer owner must understand and properly implement.

Understanding the Critical Role of Trailer Safety Chains

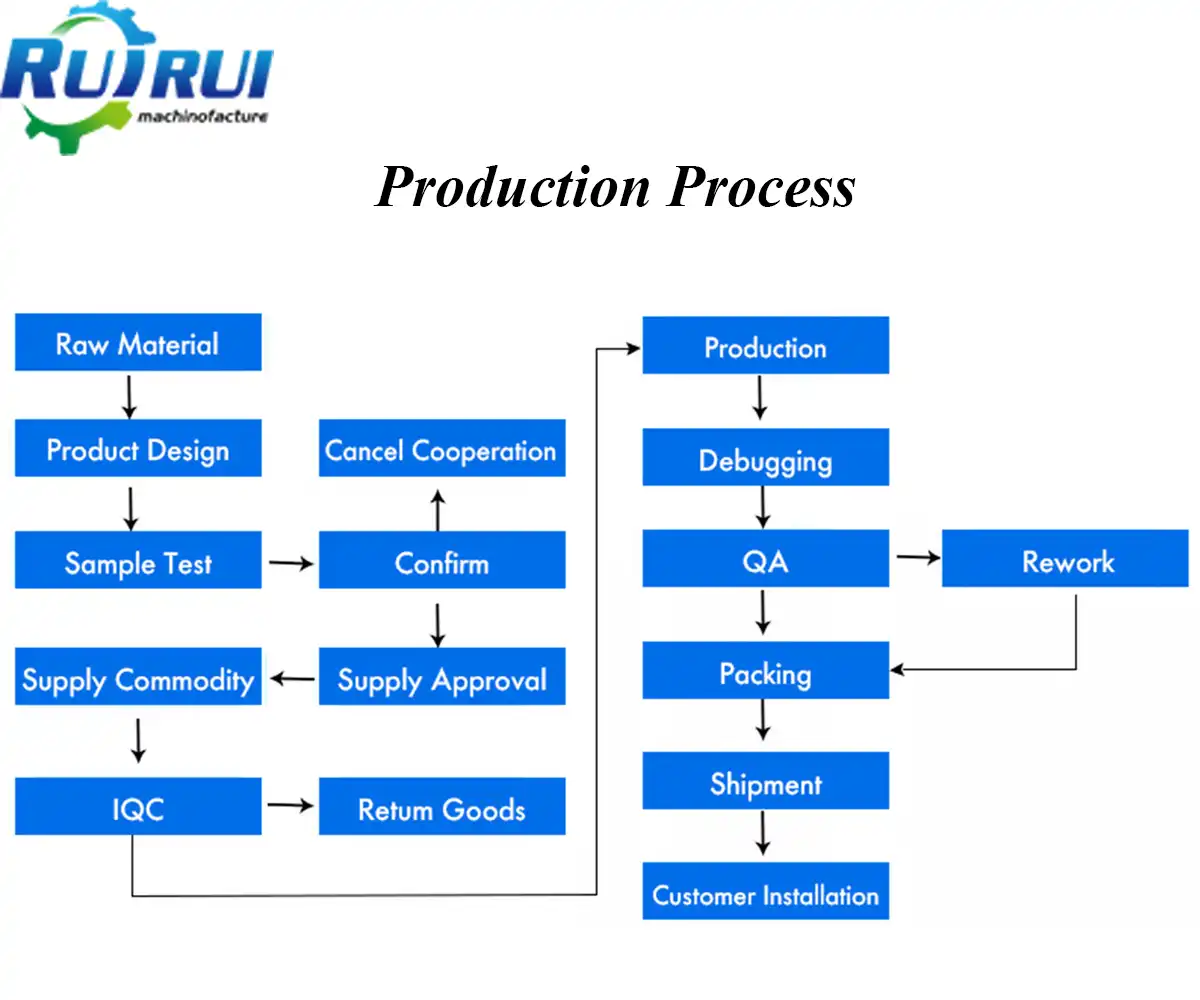

Trailer safety chains serve as the paramount backup mechanism when your primary coupling system experiences failure. These robust metal links create an essential safety barrier between complete trailer separation and maintaining vehicular control during emergency situations. Their obvious function is to keep the trailer attached to its tow vehicle in the event that the primary coupling method fails, but their importance extends far beyond this basic function. The engineering principle behind trailer safety chains involves creating a redundant safety system that can withstand the dynamic forces generated during hitch failure scenarios. When properly installed and maintained, these chains provide sufficient strength to prevent total trailer detachment while allowing controlled deceleration and maneuvering to safety. Professional manufacturers like Qingdao RUIRUI Machinary understand that trailer safety chains must be constructed from high-grade materials using advanced manufacturing processes including progressive stamping, deep drawing stamping, and specialized heat treatment processes to ensure maximum reliability under extreme stress conditions.

-

Legal Requirements and Federal Regulations

Federal regulations mandate specific requirements for trailer safety chains across all commercial and recreational applications. Section 393.70(d) requires that every full trailer must be coupled to the frame, or an extension of the frame, of the motor vehicle which tows it with one or more safety devices to prevent the towed vehicle from breaking loose in the event the tow-bar fails or becomes disconnected. These comprehensive federal standards establish minimum safety requirements that all trailer operators must follow. Trailers must have at least two safety chains. Chains should be crossed under the trailer tongue to catch it in case of a hitch failure. Chains must be rated to handle the weight of the trailer. The crossing pattern creates a crucial cradle effect that prevents the trailer tongue from dropping to the ground during separation events, maintaining better directional control and reducing the risk of jackknifing or uncontrolled trailer movement. State-specific regulations often impose additional requirements beyond federal standards. If the ultimate combined breaking strength of the two chains is equal to the gross weight of the towed vehicle(s), the requirements of § 393.70(d) are satisfied. It should be noted that some States may have more stringent requirements for safety chains. Understanding these varying requirements ensures complete legal compliance and optimal safety performance across different jurisdictions.

Proper Installation and Configuration Methods

-

Chain Positioning and Attachment Points

Correct installation of trailer safety chains requires precise attention to attachment point selection and chain routing configuration. The means of attachment of safety chains must: (a) Be located equally distant from and on opposite sides of the longitudinal centerline of the towing vehicle and of the trailer. (b) Not be common with or utilize fasteners common with a ball or coupling. This symmetric positioning ensures balanced load distribution during emergency situations. The crossed-chain configuration provides superior performance compared to parallel installations. The crossed chains will provide a cradle or safety net for the coupler, keeping it from scraping the ground until you can bring your vehicle to a complete stop. This cradle effect maintains the trailer tongue in an elevated position, preventing dangerous ground contact that could cause sudden deceleration or directional instability. Professional installation requires using appropriate hardware manufactured to exact specifications. Qingdao RUIRUI Machinary produces trailer safety chains using advanced metal stamping materials including mild steel, cold rolled steel, stainless steel, and specialized coated steel formulations. Their manufacturing capabilities encompass progressive stamping, CNC machining, laser cutting, and multiple finishing processes including powder coating, plating, anodizing, and electrophoresis to ensure maximum durability and corrosion resistance.

-

Weight Capacity and Strength Requirements

Determining proper chain capacity involves calculating the total loaded weight of the trailer system including cargo, fuel, and equipment. Safety chains or safety cables should be rated for the full loaded trailer weight, ensuring adequate strength reserves during dynamic loading conditions that occur during emergency situations. Two strong safety chains should be crisscrossed to support the trailer's coupler if it becomes disconnected from the towing vehicle. The chains should be strong enough to hold the combined weight of the vessel, engine, and trailer. This comprehensive weight consideration prevents chain failure during critical moments when maximum strength is required. Professional manufacturers implement rigorous quality control processes to verify chain strength specifications. Qingdao RUIRUI Machinary maintains ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001 certifications, ensuring their trailer safety chains meet or exceed all applicable strength and quality standards through comprehensive testing and validation procedures.

Material Selection and Manufacturing Excellence

-

Advanced Manufacturing Processes

Modern trailer safety chains require sophisticated manufacturing techniques to achieve optimal performance characteristics. Progressive stamping processes create precise chain link geometries that maximize strength while minimizing weight. Deep drawing stamping operations form complex shapes that distribute stress loads evenly throughout the chain structure. Qingdao RUIRUI Machinary utilizes fully automated robot production lines and advanced thermoplastic coating processes across eight specialized production lines, achieving an impressive annual output of 130,000 pieces. Their manufacturing expertise encompasses stamping, laser cutting, welding, CNC processing, and numerous secondary operations including polishing, deburring, wire drawing, etching, powder coating, plating, anodizing, and electrophoresis. The company's specialization in metal stamping and sheet metal processing covers diverse materials including steel, aluminum alloy, copper, stainless steel, and titanium. With extensive industry experience and superior technical capabilities, they provide customized processing services ensuring each material receives optimal treatment for specific application requirements.

-

Quality Assurance and Testing Protocols

Comprehensive quality assurance programs ensure trailer safety chains meet stringent performance standards under real-world operating conditions. Engineers collaborate closely with inspection teams to establish detailed product quality documentation from initial production through final delivery. Manufacturing processes are meticulously recorded to maintain traceability and enable continuous improvement initiatives. ISO and IAPT quality standards guide every aspect of production, ensuring strict quality control throughout the manufacturing process. Environmental management system certification demonstrates commitment to sustainable production practices while occupational health and safety management system certification protects workers and maintains consistent quality output.

Maintenance and Inspection Best Practices

Regular inspection and maintenance protocols ensure trailer safety chains maintain optimal performance throughout their service life. Visual inspections should identify signs of wear, corrosion, deformation, or mechanical damage that could compromise chain integrity during emergency situations. However, there are several things we can do to minimize the potential. Loops that connect the chains are big, and right at the bottom. If this hitch fails, the chains will be first to contact the ground and grind. This is poor placement. Use the right equipment. Proper equipment selection and installation techniques prevent premature wear and ensure reliable performance when needed most. Maintenance schedules should include lubrication of moving parts, torque verification of attachment hardware, and replacement of worn components before they reach critical failure points. Professional maintenance programs extend chain service life while maintaining peak safety performance characteristics.

Conclusion

Trailer safety chains represent the ultimate safety barrier protecting against catastrophic trailer separation events. These critical components require proper selection, installation, and maintenance to function effectively as your final safety net. Understanding legal requirements, proper installation techniques, and maintenance protocols ensures optimal protection for yourself and other road users.

Cooperate with Qingdao RUIRUI Machinary Co., LTD.

As a leading China trailer safety chains manufacturer, Qingdao RUIRUI Machinary Co., LTD. offers comprehensive solutions for all your trailer safety requirements. Established in 2016, we specialize as a China trailer safety chains supplier providing high-quality products at competitive trailer safety chains prices.

Our expertise as a China trailer safety chains factory encompasses advanced manufacturing capabilities including progressive stamping, deep drawing, CNC machining, and laser cutting. With ISO certifications and over 15 years of management experience, we deliver superior trailer safety chains for sale worldwide.

As a trusted China trailer safety chains wholesale provider, we offer customization services, OEM support, and professional technical assistance. Our High Quality trailer safety chains undergo rigorous testing and quality control processes ensuring maximum reliability and performance.

Ready to secure your trailer safety needs? Contact our experienced team at info@qdkshd.com for personalized solutions, competitive pricing, and professional support. Bookmark this page for future reference and share with colleagues who prioritize trailer safety excellence.

FAQ

Q: What is the minimum breaking strength required for trailer safety chains?

A: The combined breaking strength of both chains must equal or exceed the gross weight of the loaded trailer.

Q: Should trailer safety chains be crossed or run parallel?

A: Chains should be crossed under the trailer tongue to create a cradle that prevents the coupler from dropping to the ground.

Q: How often should trailer safety chains be inspected?

A: Inspect chains before each use and perform detailed inspections monthly or every 1,000 miles of operation.

Q: What materials are best for trailer safety chains?

A: High-grade steel with appropriate coatings provides optimal strength, durability, and corrosion resistance for most applications.

References

1. Federal Motor Carrier Safety Administration. "Safety Chain Requirements for Commercial Trailers." Department of Transportation Regulations.

2. National Highway Traffic Safety Administration. "Trailer Coupling and Safety Device Standards." Federal Motor Vehicle Safety Standards.

3. American Society for Testing and Materials. "Standard Specification for Safety Chains and Cables for Trailer Applications." ASTM International.

4. Society of Automotive Engineers. "Recommended Practice for Trailer Hitch Safety Chain Installation and Testing." SAE Technical Standards.

Send Inquiry

You may like