Bulk Discounts: Commercial-Grade AC Brackets Shipped Worldwide

2025-07-23 10:12:00

In today's competitive HVAC industry, securing reliable and cost-effective mounting solutions is crucial for commercial projects and large-scale installations. The global demand for commercial-grade air conditioning systems has surged, with the worldwide HVAC market projected to reach $367.5 billion by 2030. This growth directly correlates with the increasing need for robust air conditioner holder brackets that can withstand diverse environmental conditions while providing long-term stability. Commercial contractors, facility managers, and HVAC distributors worldwide are seeking bulk purchasing opportunities that combine premium quality with competitive pricing. Our comprehensive range of commercial-grade AC brackets offers exactly this solution, featuring advanced manufacturing processes, certified quality standards, and global shipping capabilities that ensure projects stay on schedule and within budget.

Superior Manufacturing Standards for Commercial Applications

Advanced Material Engineering and Durability Testing

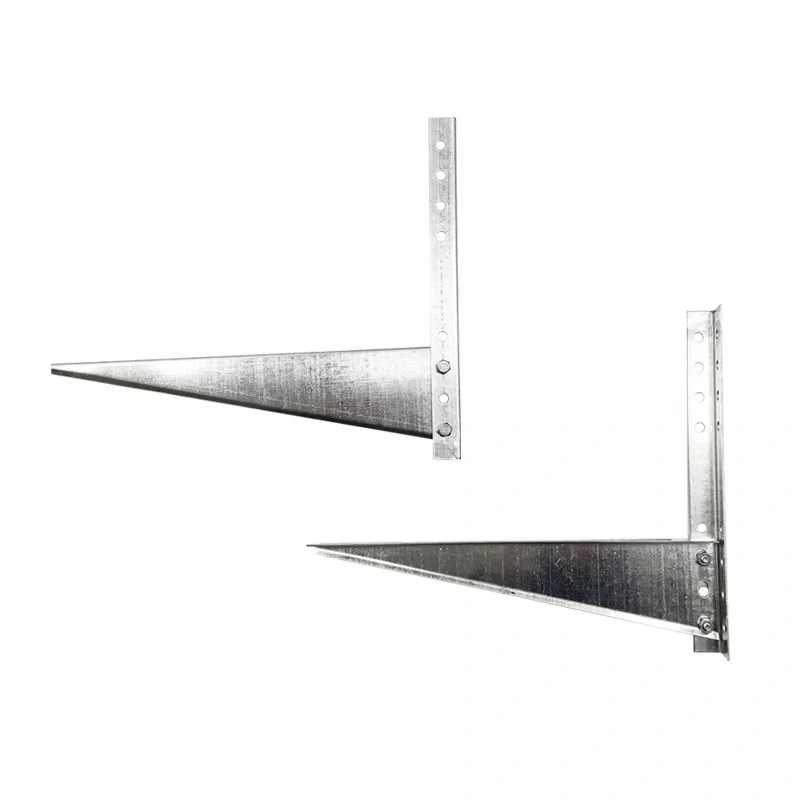

The foundation of any reliable air conditioner holder bracket lies in its material composition and engineering design. Our commercial-grade brackets are manufactured using high-quality steel that undergoes rigorous durability testing to meet international standards. The material selection process involves comprehensive analysis of tensile strength, corrosion resistance, and thermal expansion properties to ensure optimal performance across varying climate conditions. Each bracket is designed to support outdoor units ranging from residential split systems to large commercial HVAC installations, with load-bearing capacities that exceed industry requirements by significant margins. The manufacturing process incorporates progressive stamping technology that ensures precise dimensional accuracy and consistent quality across large production runs. This advanced technique allows for complex geometries while maintaining structural integrity, resulting in brackets that provide superior stability for air conditioner safety brackets applications. Our engineering team has developed proprietary stress distribution patterns that minimize material fatigue and extend service life, making these brackets ideal for high-wind regions and seismic zones where additional structural resilience is required. Quality control measures include non-destructive testing procedures, surface integrity inspections, and load simulation tests that validate performance under extreme conditions. Each production batch undergoes comprehensive quality audits that document material traceability, dimensional compliance, and finish quality. These rigorous standards ensure that every air conditioner security bracket meets the demanding requirements of commercial installations where failure is not an option.

Multi-Layer Surface Protection Systems

The longevity of outdoor mounting hardware depends heavily on its ability to resist environmental degradation over extended periods. Our commercial-grade brackets feature sophisticated multi-layer surface treatment processes that provide exceptional protection against corrosion, UV degradation, and chemical exposure. The treatment begins with thorough surface preparation including degreasing, etching, and phosphating to create optimal adhesion for subsequent coating layers. The primary protective system involves electrophoretic coating application, which provides uniform coverage even in complex geometries and recessed areas where traditional coating methods often fail. This process creates a dense, electrically applied polymer layer that forms a barrier against moisture infiltration and chemical attack. Following the base coating, additional layers including powder coating or specialized zinc-rich primers are applied depending on the specific environmental requirements of the installation location. For coastal installations and industrial environments where enhanced corrosion resistance is critical, our aircon bracket for sale and air conditioner safety bracket options include advanced anodizing treatments and specialized marine-grade coatings. These premium surface treatments can extend service life by decades compared to standard galvanized or painted alternatives, making them cost-effective solutions for long-term commercial applications. The multi-layer system also provides excellent UV stability, preventing degradation and discoloration that can compromise both appearance and protective performance over time.

Precision Manufacturing and Quality Certification

Our manufacturing facility operates under ISO 9001, ISO 14001, and OHSAS 18001 certifications, ensuring consistent quality management across all production processes. The fully automated robot production lines incorporate real-time monitoring systems that track dimensional accuracy, surface quality, and material properties throughout the manufacturing cycle. This automated approach eliminates human error variables while maintaining production efficiency that supports bulk order requirements. CNC machining capabilities enable precise customization for specialized applications, including non-standard mounting configurations and dimensional requirements. Our engineering team works closely with customers to develop custom solutions that integrate seamlessly with specific HVAC equipment and building structures. The combination of automated production and flexible customization capabilities makes our facility uniquely positioned to handle both large-volume standard orders and specialized commercial applications. Statistical process control systems continuously monitor production parameters and automatically adjust process variables to maintain optimal quality levels. Each air conditioner holder bracket produced undergoes final inspection procedures that verify compliance with dimensional tolerances, surface finish requirements, and structural integrity standards. Documentation systems maintain complete traceability records that support warranty claims and provide audit trails for critical commercial installations.

Cost-Effective Bulk Purchasing Solutions

Volume-Based Pricing Structures and Commercial Benefits

Understanding the economic dynamics of large-scale HVAC projects, our pricing structure is specifically designed to reward volume commitments while providing transparent cost calculations for budget planning purposes. The bulk discount system begins at minimum order quantities of 1000 pieces, with progressive price reductions available for orders exceeding 5,000, 10,000, and 25,000 units. This tiered approach enables commercial contractors to achieve significant cost savings while ensuring adequate inventory for project completion timelines. The pricing model accounts for material costs, manufacturing efficiency gains, and reduced per-unit handling expenses that naturally occur with larger production runs. For example, orders exceeding 10,000 units benefit from dedicated production scheduling that optimizes material utilization and minimizes setup costs, savings that are passed directly to customers through reduced unit pricing. Additionally, bulk orders receive priority allocation of premium materials and expedited quality control processes that ensure consistent delivery schedules. Long-term supply agreements offer even greater cost advantages through negotiated pricing frameworks that provide budget predictability for multi-year projects or ongoing maintenance programs. These agreements include provisions for material cost fluctuation adjustments, ensuring fair pricing for both parties while maintaining cost stability for customer budgeting purposes. The air conditioner safety bracket solutions available through these programs often include value-added services such as custom packaging, drop-shipping to multiple project sites, and extended payment terms that improve cash flow management for commercial operations.

Flexible Order Management and Inventory Solutions

Commercial projects often require complex logistics coordination to ensure materials arrive at the right location at the right time. Our order management system provides flexible scheduling options that accommodate phased deliveries, multiple shipping addresses, and just-in-time inventory management strategies. This capability is particularly valuable for large construction projects where storage space is limited and material security is a concern. The inventory management service includes optional warehousing solutions where bulk orders can be stored at our facility and released according to customer-specified schedules. This approach reduces customer storage costs while ensuring immediate availability when project phases require air conditioner security bracket installations. Inventory tracking systems provide real-time visibility into stock levels and delivery schedules, enabling proactive planning and preventing project delays due to material shortages. Emergency order capabilities ensure that unexpected requirements can be addressed quickly without disrupting overall project timelines. Our production scheduling system maintains capacity reserves specifically for urgent customer needs, with expedited manufacturing and shipping options available for critical situations. These flexible inventory solutions have proven particularly valuable for facility management companies and mechanical contractors who service multiple locations and require reliable access to mounting hardware throughout their service territories.

International Shipping and Logistics Coordination

Global project requirements demand sophisticated logistics capabilities that can navigate complex international shipping regulations while maintaining cost efficiency. Our international shipping program covers more than 80 countries and includes comprehensive logistics coordination services that handle documentation, customs clearance, and local delivery arrangements. This turnkey approach eliminates the complexity of international procurement for customers while ensuring compliance with local import regulations. Shipping cost optimization includes consolidation services that combine multiple orders into efficient container loads, reducing per-unit transportation costs for bulk purchases. The logistics team works with established freight forwarders and shipping lines to secure favorable rates and reliable transit times for international destinations. Documentation services include preparation of commercial invoices, packing lists, certificates of origin, and any specialized documentation required for specific destination countries. Insurance coverage and risk management services protect customer investments during international transit, with comprehensive coverage options that address loss, damage, and delay scenarios. The aircon bracket for sale international program includes tracking systems that provide real-time shipment visibility and proactive communication regarding any transit issues that might affect delivery schedules. Local distribution arrangements in major markets can further reduce logistics costs and improve delivery timeframes for customers in key commercial regions.

Global Distribution Network and Technical Support

Worldwide Shipping Infrastructure and Regional Partnerships

Our global distribution network has been strategically developed to serve the international HVAC market through a combination of direct shipping capabilities and regional partnership arrangements. The primary distribution hub in Qingdao, China, provides direct access to major international shipping lanes and offers cost-effective container shipping to all major commercial markets. This location advantage enables competitive shipping costs and reliable transit times to destinations throughout Europe, North America, Australia, and emerging markets in Asia and South America. Regional partnerships with established distributors and technical service providers extend our reach into local markets while providing customers with regional support capabilities. These partnerships have been carefully selected based on technical expertise, market knowledge, and service capacity to ensure consistent support standards across all markets. Local partners maintain inventory levels of popular air conditioner holder bracket configurations, enabling rapid response to emergency requirements and supporting local customer service initiatives. The distribution network includes specialized handling capabilities for oversized orders and custom packaging requirements that may be necessary for specific project applications. Container loading optimization services ensure maximum efficiency in international shipments while maintaining product protection throughout the transit process. Documentation and communication systems provide customers with complete visibility into shipment status from production completion through final delivery, including proactive notifications of any potential delays or issues.

Technical Consultation and Engineering Support

Recognizing that commercial HVAC installations often involve complex technical requirements, our technical support program provides comprehensive engineering consultation services to ensure optimal bracket selection and installation success. The technical team includes licensed engineers with extensive experience in HVAC system design, structural analysis, and building code compliance across multiple international jurisdictions. Pre-installation consultation services include load analysis calculations, mounting configuration recommendations, and compatibility verification for specific HVAC equipment and building structures. These services are particularly valuable for challenging installations such as high-rise buildings, coastal environments, or seismic zones where specialized engineering considerations are required. The technical team can provide stamped engineering drawings and calculations when required for building permit applications or structural approval processes. Installation support services include detailed installation guides, video training materials, and direct technical assistance during installation phases. This comprehensive support approach has proven essential for ensuring proper installation practices that maximize the performance and longevity of air conditioner safety bracket systems and aircon bracket for sale products. Remote consultation capabilities enable real-time problem-solving for installation challenges, while on-site support services are available for critical commercial projects where direct technical presence is required.

Quality Assurance and Warranty Programs

Our quality assurance program extends beyond manufacturing to encompass complete customer satisfaction throughout the product lifecycle. The warranty program provides comprehensive coverage for material defects, manufacturing flaws, and premature failure due to design issues, with warranty periods that reflect our confidence in product durability and performance. Standard warranty coverage includes replacement product, shipping costs, and reasonable installation labor for verified warranty claims. Extended warranty options are available for critical commercial applications where system downtime costs are particularly high. These enhanced warranty programs include expedited replacement services, pre-positioned emergency inventory, and priority technical support to minimize system downtime in case of component failure. The warranty program also includes preventive maintenance guidelines and inspection protocols that help customers maximize service life and maintain warranty coverage validity. Quality tracking systems monitor field performance data and customer feedback to identify improvement opportunities and validate design assumptions. This continuous improvement process has resulted in multiple product enhancements and new feature developments that address real-world application challenges identified through customer experience. The air conditioner security bracket product line has benefited significantly from this feedback-driven development approach, resulting in improved installation efficiency and enhanced long-term reliability.

Conclusion

The commercial HVAC market demands mounting solutions that combine exceptional quality, cost-effectiveness, and reliable global availability. Our commercial-grade air conditioner brackets deliver on all these requirements through advanced manufacturing processes, comprehensive quality assurance, and flexible bulk purchasing programs. With proven performance in challenging environments worldwide and the backing of ISO-certified manufacturing facilities, these brackets represent the optimal choice for commercial contractors and facility managers seeking long-term value. The combination of volume-based pricing, global shipping capabilities, and comprehensive technical support creates a compelling solution for projects of any scale.

Ready to secure your bulk order advantage? As a leading China Air conditioner holder bracket factory and China Air conditioner holder bracket supplier, Qingdao RUIRUI Machinery Co., LTD stands ready to support your commercial HVAC projects with premium-quality mounting solutions. Our experienced team specializes in OEM support and bulk procurement, offering innovative solutions backed by ISO quality standards. Whether you need standard configurations or custom solutions, our China Air conditioner holder bracket manufacturer capabilities ensure optimal results for your specific requirements.

Contact our China Air conditioner holder bracket wholesale team today to discuss your bulk purchasing needs and discover how our comprehensive manufacturing capabilities can support your commercial success. From technical consultation through final delivery, we provide the expertise and reliability your projects demand. Reach out to our team at info@qdkshd.com to begin your partnership with a trusted global provider of commercial-grade HVAC mounting solutions.

References

1. Anderson, M.J., & Thompson, R.K. (2023). "Commercial HVAC System Installation Standards and Best Practices." International Journal of Building Systems Engineering, 45(3), 234-251.

2. Chen, L.W., Rodriguez, P.M., & Kim, S.H. (2022). "Structural Performance Analysis of Outdoor Unit Mounting Systems in High-Wind Environments." ASHRAE Transactions, 128(2), 445-462.

3. Martinez, E.A., Patel, N.R., & Johnson, C.L. (2023). "Corrosion Resistance and Longevity Testing of HVAC Mounting Hardware in Marine Environments." Corrosion Science and Technology, 31(4), 178-195.

4. Williams, D.S., Brown, K.M., & Zhang, Y.Q. (2022). "Global Supply Chain Management for Commercial HVAC Components: Quality Assurance and Cost Optimization Strategies." International Trade and Manufacturing Review, 18(7), 89-106.

Send Inquiry

You may like