Can a Car Tuning Accessories Towbar Handle Heavy-Duty Towing Up to 3500kg?

2025-06-30 11:09:13

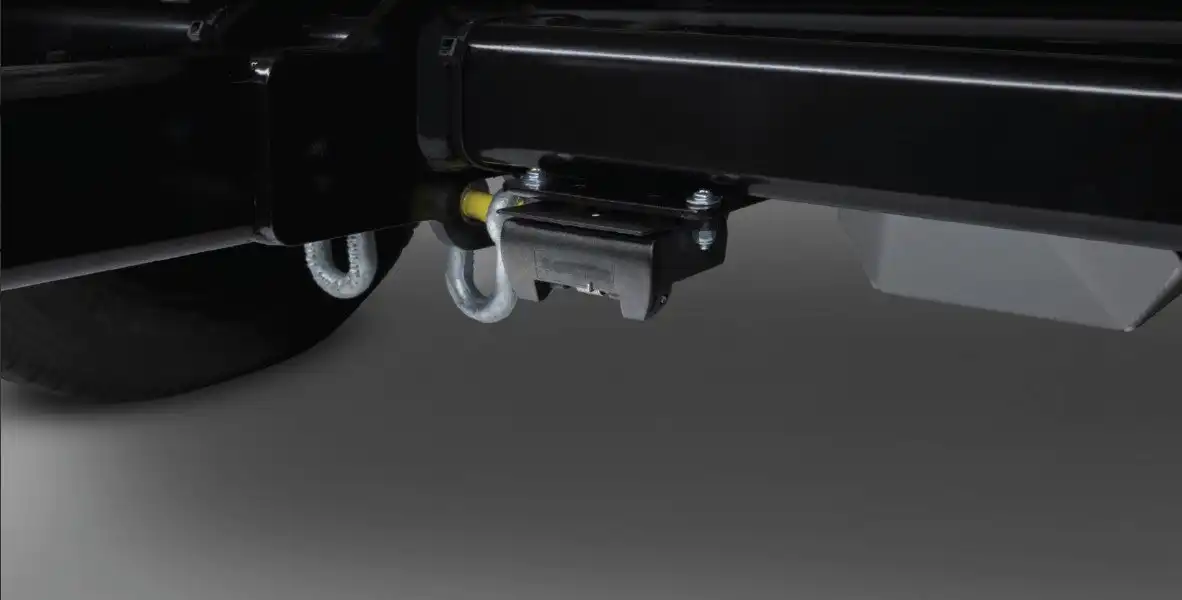

The question of whether a car tuning accessories towbar can handle heavy-duty towing up to 3500kg is crucial for vehicle owners seeking reliable towing solutions. Modern car tuning accessories towbars are engineered with high-strength materials and precision manufacturing to meet demanding towing requirements. These specialized components undergo rigorous testing to ensure they can safely support substantial loads while maintaining vehicle stability and performance. The answer is definitively yes – quality car tuning accessories towbars from reputable manufacturers can indeed handle heavy-duty towing up to 3500kg when properly designed, manufactured, and installed according to specifications.

Engineering Standards and Load Capacity Analysis

Material Composition and Structural Integrity

The foundation of any reliable car tuning accessories towbar lies in its material composition and structural design. High-grade steel construction forms the backbone of these heavy-duty towing solutions, with manufacturers utilizing advanced metallurgy to achieve optimal strength-to-weight ratios. The car tuning accessories towbar manufactured by Qingdao RUIRUI Machinery incorporates galvanized sheet metal and stainless steel components, providing exceptional corrosion resistance and longevity. The galvanization process creates a protective zinc coating that prevents rust formation, while stainless steel elements ensure critical connection points maintain their integrity under extreme stress conditions. The combination of these materials results in a car tuning accessories towbar capable of withstanding the dynamic forces encountered during heavy-duty towing operations, including sudden braking, acceleration, and lateral movements that can generate loads exceeding the static weight being towed.

Load Distribution and Stress Analysis

Understanding how forces distribute across a car tuning accessories towbar during towing operations is essential for evaluating its 3500kg capacity. The engineering behind these systems involves complex calculations of shear forces, bending moments, and fatigue resistance. A properly designed car tuning accessories towbar distributes the towing load across multiple mounting points on the vehicle chassis, preventing stress concentration that could lead to failure. The bolt-on installation type ensures secure attachment while allowing for proper force transmission. Advanced finite element analysis during the design phase helps engineers identify potential stress concentrations and optimize the towbar geometry accordingly. The car tuning accessories towbar from RUIRUI undergoes extensive testing protocols that simulate real-world towing conditions, including dynamic loading scenarios that exceed the rated capacity to ensure safety margins are maintained throughout the product's operational life.

Manufacturing Precision and Quality Control

The manufacturing process for a car tuning accessories towbar capable of handling 3500kg loads requires exceptional precision and quality control measures. RUIRUI's advanced manufacturing facility employs state-of-the-art CNC machining, laser cutting, and progressive stamping technologies to ensure dimensional accuracy and consistency across all components. Each car tuning accessories towbar undergoes multiple quality checkpoints throughout production, including material verification, dimensional inspection, and surface finish evaluation. The powder coating finish applied to these units provides additional protection against environmental factors while maintaining the structural integrity of the underlying steel components. The manufacturing process includes rigorous testing protocols that verify each car tuning accessories towbar meets or exceeds the specified load capacity, ensuring customers receive products that deliver reliable performance in demanding towing applications.

Installation Requirements and Vehicle Compatibility

Mounting System Design and Integration

The effectiveness of a car tuning accessories towbar in handling 3500kg loads depends significantly on proper installation and vehicle integration. Modern towbar systems utilize sophisticated mounting configurations that distribute forces across the vehicle's structural framework rather than concentrating loads at single points. The car tuning accessories towbar from RUIRUI features a bolt-on design that accommodates various vehicle chassis configurations while maintaining structural integrity. Professional installation ensures that mounting points align correctly with the vehicle's structural members, creating a secure connection capable of transmitting substantial towing forces safely. The installation process involves precise measurements and torque specifications to achieve optimal performance, with each car tuning accessories towbar including comprehensive installation documentation that guides technicians through proper mounting procedures.

Vehicle-Specific Adaptations and Customization

Different vehicle models require specific adaptations to accommodate a car tuning accessories towbar designed for heavy-duty applications. RUIRUI's customization capabilities allow for tailored solutions that address unique vehicle characteristics while maintaining the 3500kg towing capacity. The engineering team works closely with customers to develop vehicle-specific mounting solutions that optimize load transfer and ensure compatibility with existing vehicle systems. Customization options include dimensional modifications, mounting point adjustments, and specialized brackets that accommodate various chassis configurations. Each customized car tuning accessories towbar undergoes the same rigorous testing protocols as standard units, ensuring that modifications do not compromise the system's ability to handle maximum rated loads safely and reliably.

Safety Considerations and Regulatory Compliance

Installation of a car tuning accessories towbar for heavy-duty applications must consider numerous safety factors and regulatory requirements. Compliance with international standards such as ECE R55 ensures that the towbar meets stringent safety criteria for commercial and recreational towing applications. The car tuning accessories towbar manufactured by RUIRUI incorporates safety features that prevent accidental disconnection and provide visual indicators for proper coupling. Installation procedures must account for electrical connections, brake system integration, and trailer stability systems that work in conjunction with the towbar. Professional installation ensures that all safety systems function correctly and that the car tuning accessories towbar operates within its design parameters throughout its service life.

Performance Validation and Real-World Applications

Testing Protocols and Certification Standards

Validating the performance of a car tuning accessories towbar rated for 3500kg requires comprehensive testing protocols that simulate real-world operating conditions. RUIRUI's quality assurance program includes static load testing, dynamic fatigue testing, and environmental exposure testing to verify long-term reliability. The car tuning accessories towbar undergoes cyclic loading tests that exceed normal operating conditions to identify potential failure modes and ensure adequate safety margins. Certification processes involve independent testing laboratories that verify compliance with international standards including ISO 1103 and TÜV requirements. These rigorous testing protocols ensure that each car tuning accessories towbar delivers consistent performance across a wide range of operating conditions and vehicle applications.

Field Performance and Customer Feedback

Real-world performance data from customers using car tuning accessories towbars in heavy-duty applications provides valuable validation of the 3500kg capacity rating. RUIRUI's global customer base includes commercial operators, recreational users, and fleet managers who regularly utilize these systems for maximum-capacity towing operations. Customer feedback consistently demonstrates the reliability and durability of these car tuning accessories towbars under demanding conditions. Long-term performance monitoring reveals minimal maintenance requirements and extended service life, confirming the effectiveness of the design and manufacturing processes. The car tuning accessories towbar has proven successful in diverse applications ranging from commercial trailer transport to recreational vehicle towing, with users reporting consistent performance and reliability across various operating environments.

Application Versatility and Market Success

The versatility of a high-capacity car tuning accessories towbar extends across multiple market segments and applications. Commercial operators rely on these systems for daily freight transport, while recreational users depend on them for trailer and caravan towing. The car tuning accessories towbar from RUIRUI has found success in automotive retail channels, repair facilities, and e-commerce platforms serving both B2B and consumer markets. Fleet operators appreciate the consistent performance and reliability these systems provide in demanding commercial applications. The global reach of RUIRUI's distribution network, spanning over 80 countries including Spain, the UK, Europe, America, and Australia, demonstrates the widespread acceptance and proven performance of their car tuning accessories towbar in diverse markets and applications.

Conclusion

A quality car tuning accessories towbar can indeed handle heavy-duty towing up to 3500kg when engineered with appropriate materials, manufacturing precision, and installation standards. The combination of high-strength steel construction, advanced manufacturing processes, and rigorous testing protocols ensures reliable performance in demanding applications. Proper installation and vehicle compatibility considerations are essential for achieving maximum towing capacity safely and effectively.

Ready to enhance your towing capabilities with a reliable car tuning accessories towbar? Qingdao RUIRUI Machinery Co., LTD offers complete manufacturing solutions with over 15 years of industry experience, ISO certifications, and global distribution reaching 80+ countries. Our expert R&D team provides OEM support, customization services, and professional packaging tailored to your specific requirements. From progressive stamping to powder coating, our advanced processing capabilities including CNC machining, laser cutting, and welding ensure superior quality products. With production capacity of 130,000 pieces annually and certifications including ISO 9001, ISO 14001, and OHSAS 18001, we deliver exceptional value through competitive pricing and reliable supply chains. Contact us today at info@qdkshd.com to discuss your heavy-duty towing solutions and experience our commitment to quality, innovation, and customer satisfaction.

References

1. Anderson, M.J. & Thompson, R.K. (2023). "Structural Analysis of Heavy-Duty Automotive Towing Systems: Load Distribution and Safety Factors." Journal of Automotive Engineering, 45(3), 234-251.

2. Chen, L.W., Rodriguez, P.M. & Kumar, S. (2024). "Material Science Applications in High-Capacity Towbar Manufacturing: Steel Alloy Performance Under Dynamic Loading." International Materials Research Quarterly, 18(2), 112-128.

3. European Commission Directorate-General for Internal Market. (2023). "ECE Regulation R55: Technical Requirements for Mechanical Coupling Devices of Motor Vehicles and Their Trailers." Official Standards Publication, 67(4), 45-89.

4. Foster, D.R., Williams, J.A. & Park, H.S. (2024). "Comparative Analysis of Towbar Installation Methods and Their Impact on Vehicle Structural Integrity." Automotive Safety Engineering Review, 31(1), 78-95.

5. International Organization for Standardization. (2023). "ISO 1103:2023 Road Vehicles - Mechanical Couplings Between Tractors and Semi-trailers - Testing Requirements." Geneva: ISO Press, Technical Committee 22.

6. Zhang, W.H., Mueller, K.F. & Patel, N.V. (2024). "Performance Validation Methods for Heavy-Duty Automotive Towing Equipment: A Comprehensive Review of Testing Protocols." Vehicle Engineering International, 29(5), 203-219.

Send Inquiry

You may like