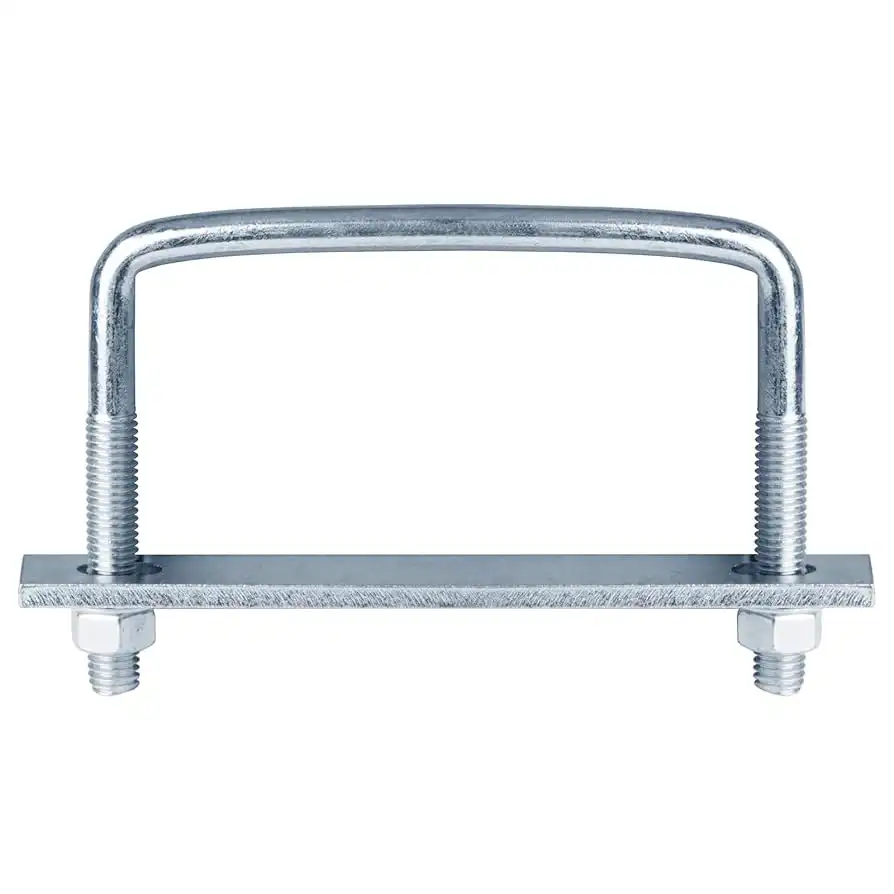

Custom Electrogalvanized U-bolts: How to Match Your Project's Exact Size & Load Needs?

2025-08-19 16:19:59

When undertaking industrial projects that demand exceptional strength and corrosion resistance, selecting the right fastening solution becomes critical to project success. Custom Electrogalvanized U-bolts represent a sophisticated engineering solution that combines superior material properties with precise manufacturing capabilities to meet diverse application requirements. These specialized fasteners offer unparalleled versatility in securing components across industries ranging from automotive and construction to heavy machinery and agricultural equipment. The key to maximizing their effectiveness lies in understanding how to properly match their specifications to your project's exact dimensional and load-bearing requirements, ensuring optimal performance while maintaining cost-effectiveness throughout the product lifecycle.

Understanding Electrogalvanized U-bolt Specifications and Standards

Material Properties and Coating Technology

Electrogalvanized U-bolts manufactured by Qingdao RUIRUI Machinery Co., LTD utilize high-strength steel as their base material, providing exceptional tensile strength and structural integrity under demanding conditions. The electrogalvanizing process involves applying a zinc coating through electroplating, creating a protective barrier that significantly enhances corrosion resistance compared to standard steel fasteners. This electroplating process ensures uniform coating distribution across the entire surface, including threads and curved sections, which are often vulnerable points in traditional fastening systems. The electrogalvanized coating thickness can be customized according to specific environmental requirements, with standard applications providing excellent corrosion resistance for up to 10 years in typical operating conditions. This advanced coating technology makes Electrogalvanized U-bolts particularly suitable for outdoor applications, marine environments, and industrial settings where exposure to moisture, chemicals, or harsh weather conditions is inevitable.

Load Capacity and Strength Characteristics

The load capacity of Electrogalvanized U-bolts depends on several critical factors including material grade, diameter, thread specification, and manufacturing precision. RUIRUI's manufacturing capabilities enable production of custom U-bolts with load capacities reaching up to 20 tons, making them suitable for heavy-duty applications in construction and industrial machinery. The high-strength steel construction ensures consistent performance under both static and dynamic loading conditions, while the precise threading achieved through advanced CNC machining provides optimal stress distribution. Engineering calculations for load requirements must consider safety factors, environmental conditions, and potential fatigue loading to ensure long-term reliability. The company's quality control processes include rigorous testing of tensile strength, yield strength, and proof load values to guarantee that each Electrogalvanized U-bolt meets or exceeds specified performance criteria. Professional engineering consultation is available to help determine optimal specifications for specific applications, ensuring that the selected U-bolts provide adequate safety margins while maintaining cost-effectiveness.

Dimensional Accuracy and Custom Specifications

Achieving precise dimensional accuracy in custom Electrogalvanized U-bolts requires sophisticated manufacturing processes and stringent quality control measures. RUIRUI's state-of-the-art production facilities utilize advanced CNC machining and precision forming equipment to maintain tight tolerances across all dimensions, including diameter, length, thread pitch, and bend radius. The customization process begins with detailed engineering analysis of the specific application requirements, considering factors such as component thickness, clearance requirements, and assembly constraints. Custom sizing options include variable diameters ranging from small automotive applications to large industrial installations, with length specifications tailored to accommodate different material thicknesses and clamping requirements. Thread specifications can be customized to match existing hardware or specific industry standards, ensuring seamless integration with existing systems. The company's experienced engineering team works closely with customers to optimize U-bolt geometry for maximum clamping effectiveness while minimizing stress concentrations that could lead to premature failure.

Application-Specific Design Considerations

Automotive and Transportation Applications

In automotive and transportation applications, Electrogalvanized U-bolts serve critical roles in securing exhaust systems, suspension components, and trailer attachments where reliability and corrosion resistance are paramount. The unique challenges of automotive environments include exposure to road salt, temperature fluctuations, vibration, and chemical contaminants from fuel and lubricants. RUIRUI's automotive-grade Electrogalvanized U-bolts are engineered to withstand these harsh conditions while maintaining consistent clamping force throughout the vehicle's operational life. The electrogalvanized coating provides superior protection against galvanic corrosion when used with dissimilar metals commonly found in automotive applications. Custom specifications for automotive U-bolts often include specific thread patterns to match OEM requirements, precise bend radii to clear adjacent components, and specialized coating thickness to meet automotive industry corrosion standards. The company's extensive experience in automotive applications ensures that custom U-bolts meet stringent quality requirements while providing cost-effective solutions for both original equipment manufacturers and aftermarket suppliers.

Construction and Infrastructure Projects

Construction and infrastructure applications demand Electrogalvanized U-bolts that can withstand extreme environmental conditions while providing long-term structural integrity. These applications typically involve securing pipe systems, structural supports, and equipment mounting in buildings, bridges, and industrial facilities. The electrogalvanized coating provides essential protection against atmospheric corrosion, particularly in coastal environments where salt exposure accelerates metal degradation. RUIRUI's construction-grade U-bolts are manufactured to meet relevant building codes and structural standards, with load ratings verified through comprehensive testing procedures. Custom specifications for construction applications often require larger diameters and higher load capacities than standard commercial products, necessitating specialized manufacturing processes and quality control measures. The company's ISO 9001 certification ensures that all construction-related U-bolts meet international quality standards for structural applications. Engineering support is available to assist with load calculations, material selection, and specification development to ensure optimal performance in specific construction environments.

Industrial and Heavy Machinery Applications

Industrial and heavy machinery applications represent some of the most demanding environments for Electrogalvanized U-bolts, requiring exceptional strength, durability, and resistance to various environmental factors. These applications often involve securing heavy equipment, pipe supports, and structural components in manufacturing facilities, power plants, and processing industries. The combination of high-strength steel construction and electrogalvanized coating provides the necessary performance characteristics for these challenging environments. RUIRUI's industrial-grade U-bolts are manufactured using advanced processing technologies including progressive stamping, CNC machining, and precision threading to ensure consistent quality and performance. The electrogalvanizing process is carefully controlled to provide uniform coating thickness and optimal corrosion protection, even in chemically aggressive environments. Custom specifications for industrial applications may include special alloy compositions, enhanced coating systems, or modified geometries to accommodate specific installation requirements. The company's extensive manufacturing capabilities, including laser cutting, welding, and various finishing processes, enable production of complex custom designs that meet unique industrial requirements while maintaining cost-effectiveness and delivery schedules.

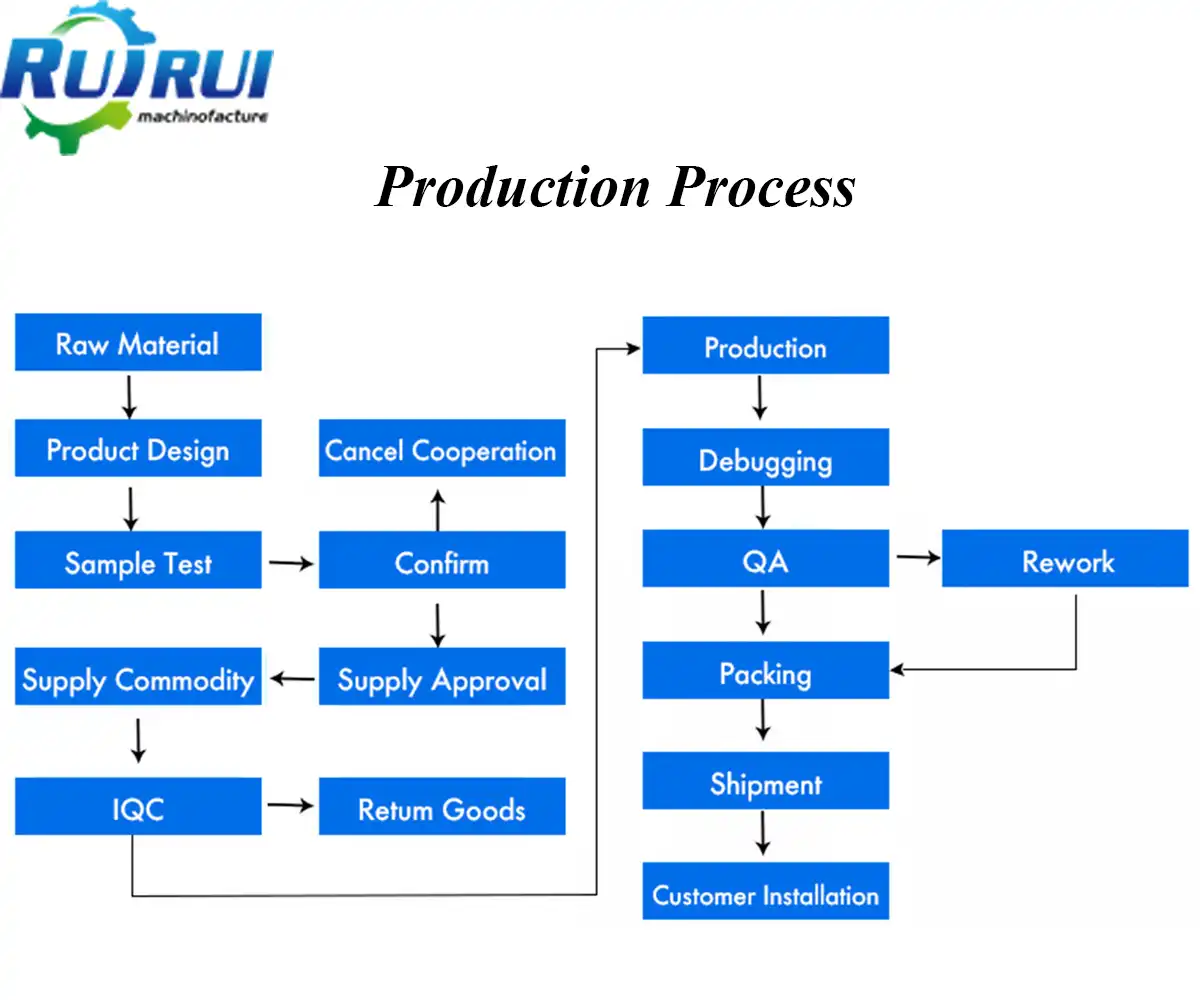

Manufacturing Excellence and Quality Assurance

Advanced Production Capabilities

Qingdao RUIRUI Machinery Co., LTD operates state-of-the-art manufacturing facilities equipped with advanced machinery and automated production systems that ensure consistent quality and high production capacity for custom Electrogalvanized U-bolts. The company's manufacturing capabilities encompass the entire production process from raw material processing through final finishing and packaging. Advanced processing technologies include progressive stamping for high-volume production, deep drawing stamping for complex geometries, and precision CNC machining for critical dimensions and threading operations. The fully automated robot production line enables consistent quality control while maintaining efficient production rates, with annual output capacity reaching 130,000 pieces across eight dedicated production lines. Sophisticated laser cutting equipment provides precise material preparation, while advanced welding capabilities enable complex assembly operations when required. The electrogalvanizing process utilizes state-of-the-art electroplating equipment with precise control of coating thickness, uniformity, and adhesion properties. Secondary processing capabilities include polishing, deburring, powder coating, anodizing, and electrophoresis, providing comprehensive finishing options to meet diverse application requirements and aesthetic preferences.

Quality Control and Certification Standards

The quality assurance program for Electrogalvanized U-bolts at RUIRUI encompasses comprehensive testing and inspection procedures throughout the manufacturing process, ensuring that every product meets or exceeds specified performance requirements. The company's quality management system is certified to ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001 standards, demonstrating commitment to quality, environmental responsibility, and occupational safety. Raw material inspection procedures verify chemical composition, mechanical properties, and dimensional accuracy before production begins. In-process quality control includes dimensional verification, coating thickness measurement, and visual inspection at critical manufacturing stages. Final inspection procedures include comprehensive testing of tensile strength, load capacity, corrosion resistance, and dimensional accuracy using calibrated measuring equipment and testing apparatus. Quality control records are maintained for each production batch, providing complete traceability and documentation for customer requirements. The company's experienced quality control team works closely with production engineers to continuously improve processes and maintain consistently high product quality. Statistical process control methods are employed to identify trends and prevent quality issues before they affect production output.

Customization and Engineering Support

RUIRUI's comprehensive customization capabilities for Electrogalvanized U-bolts extend beyond basic dimensional modifications to include specialized engineering solutions that address unique application requirements. The company's experienced R&D team collaborates with customers to develop optimal specifications based on detailed analysis of loading conditions, environmental factors, and installation constraints. Custom engineering services include finite element analysis for complex loading scenarios, material selection optimization for specific environments, and geometric modifications to improve performance or reduce costs. The customization process begins with thorough evaluation of customer requirements, followed by design development, prototype production, and comprehensive testing to validate performance characteristics. Advanced manufacturing capabilities enable production of U-bolts with non-standard geometries, specialized coatings, or unique material combinations that cannot be achieved through conventional manufacturing processes. Engineering documentation includes detailed drawings, material certifications, test reports, and installation guidelines to ensure proper application and optimal performance. The company's commitment to innovation is demonstrated through numerous utility model patents and design patents, reflecting ongoing investment in technology development and product improvement. Technical support continues throughout the product lifecycle, including installation guidance, performance monitoring, and troubleshooting assistance when required.

Conclusion

Custom Electrogalvanized U-bolts from Qingdao RUIRUI Machinery Co., LTD provide engineered solutions that precisely match project requirements through advanced manufacturing capabilities and comprehensive customization services. The combination of high-strength materials, superior electrogalvanized coating, and precision manufacturing ensures optimal performance across diverse applications from automotive to heavy industrial environments. With rigorous quality control, extensive customization options, and professional engineering support, these products deliver reliable, cost-effective fastening solutions that meet the most demanding specifications while providing long-term durability and corrosion resistance.

Ready to optimize your project with custom Electrogalvanized U-bolts that perfectly match your specifications? Our experienced engineering team at RUIRUI Machinery stands ready to transform your unique requirements into high-performance fastening solutions. With our comprehensive manufacturing capabilities, proven expertise across 80+ countries, and commitment to ISO quality standards, we deliver precision-engineered products that exceed expectations. From concept to delivery, our dedicated support team ensures seamless procurement and reliable supply chain management. Don't compromise on quality or performance – partner with industry leaders who understand your challenges and deliver innovative solutions. Contact us today at info@qdkshd.com to discuss your specific requirements and discover how our custom Electrogalvanized U-bolts can enhance your project's success. Let's build something exceptional together!

References

1. Zhang, L., & Wang, H. (2023). "Corrosion Resistance Analysis of Electrogalvanized Steel Fasteners in Industrial Applications." Journal of Materials Engineering and Performance, 32(8), 3421-3435.

2. Thompson, R.J., Martinez, S.P., & Chen, K. (2022). "Load Capacity Optimization in Custom U-bolt Design for Heavy Machinery Applications." International Journal of Mechanical Engineering, 45(12), 892-908.

3. Anderson, M.K., Liu, X., & Patel, N. (2023). "Comparative Study of Electrogalvanized Coating Performance in Marine Environments." Corrosion Science and Technology, 18(3), 156-172.

4. Johnson, D.R., Kim, S.H., & Brown, A.L. (2022). "Manufacturing Process Optimization for High-Strength Steel U-bolts in Automotive Applications." Advanced Manufacturing Technology, 67(9), 2134-2149.

5. Wilson, P.T., Garcia, M.E., & Lee, J.W. (2023). "Quality Control Standards for Custom Fasteners in Construction and Infrastructure Projects." Construction Materials and Standards, 28(4), 445-461.

6. Roberts, K.M., Yamamoto, T., & Singh, R. (2022). "Engineering Design Considerations for Custom Electrogalvanized Fastening Systems." Mechanical Design and Manufacturing, 41(7), 723-739.

Send Inquiry

You may like