Custom Trailer Hitch Pins Bulk — Trends & Future Demand Insights

2025-12-25 09:54:12

Picture this scenario: you're hauling critical equipment across state lines when your trailer hitch pin fails, leaving you stranded on the highway with a detached load and mounting costs. For fleet managers, logistics operators, and bulk purchasers, inferior Custom Trailer Hitch Pins Bulk can spell disaster. This comprehensive analysis explores current market trends, emerging technologies, and future demand projections for Custom Trailer Hitch Pins Bulk, helping industry professionals make informed procurement decisions that ensure safety, reliability, and operational efficiency in an increasingly competitive towing accessories market.

Market Growth Trajectory for Custom Trailer Hitch Pins Bulk

The global trailer hitch market demonstrates robust expansion potential, with industry analysts projecting substantial growth through 2033. Market valuations reveal that the sector reached approximately 775 million dollars in 2024, with forecasts indicating growth to nearly one billion dollars by 2033, representing a compound annual growth rate between 2.9 and 3.2 percent. This steady expansion directly impacts the Custom Trailer Hitch Pins Bulk segment, as hitch pins constitute critical safety components within the broader towing accessories ecosystem. Several factors drive this upward trajectory, including increased recreational vehicle ownership, expanding e-commerce logistics requiring trailer transportation, and rising outdoor activity participation rates that have surged by over thirty-four percent in recent years. The demand for Custom Trailer Hitch Pins Bulk specifically benefits from bulk purchasing patterns among commercial fleet operators, trailer manufacturers, and aftermarket distributors who require consistent quality and competitive pricing structures. North America maintains market dominance, capturing approximately forty percent of global revenue, largely due to high pickup truck and sport utility vehicle ownership rates where over sixty-two percent of these vehicles incorporate factory-equipped or aftermarket towing capabilities. Regional markets in Europe and Asia-Pacific demonstrate parallel growth patterns, contributing twenty-eight percent and twenty-two percent respectively to overall market share, indicating widespread international demand for reliable hitch pin solutions.

Manufacturing Innovations Reshaping Custom Trailer Hitch Pins Bulk Production

Contemporary manufacturing processes have revolutionized Custom Trailer Hitch Pins Bulk production through advanced metal fabrication technologies. Progressive stamping and deep drawing stamping techniques enable manufacturers to produce hitch pins with exceptional dimensional accuracy while maintaining cost-effectiveness for bulk orders. These precision manufacturing methods ensure that each Custom Trailer Hitch Pins Bulk component meets stringent tolerances required for safety-critical towing applications, where even minor dimensional variations can compromise load security and create liability risks. Material science advancements significantly enhance Custom Trailer Hitch Pins Bulk performance characteristics. Modern production facilities utilize diverse materials including high-strength steel alloys, corrosion-resistant stainless steel, and specialized coated steel formulations that extend service life in harsh environmental conditions. Surface treatment innovations such as powder coating, zinc plating, electrophoresis, and anodizing processes provide superior corrosion protection, addressing a primary failure mode for hitch pins exposed to road salt, moisture, and temperature extremes. These protective finishes reduce replacement frequency, delivering long-term value for bulk purchasers managing large equipment fleets or distribution inventories. Computer numerical control machining capabilities allow manufacturers to produce Custom Trailer Hitch Pins Bulk with complex geometries and customized specifications that accommodate specialized towing applications. Whether producing standard half-inch or five-eighths-inch diameter pins or engineering custom dimensions for proprietary hitch systems, modern CNC equipment maintains production consistency across bulk order quantities ranging from hundreds to millions of units. This manufacturing flexibility particularly benefits original equipment manufacturers developing proprietary trailer systems and aftermarket suppliers serving diverse customer requirements across multiple vehicle classes and towing capacity ranges.

Technological Advancements Driving Custom Trailer Hitch Pins Bulk Evolution

Smart technology integration represents an emerging trend within the towing accessories sector that may influence future Custom Trailer Hitch Pins Bulk designs. Industry leaders have introduced sensor-equipped hitches capable of real-time monitoring, weight distribution tracking, and maintenance alert systems. While traditional hitch pins remain purely mechanical components, this technological evolution creates potential for enhanced pin designs incorporating wear indicators, installation verification systems, or electronic locking mechanisms that provide additional security for high-value loads. Such innovations could command premium pricing in specialized bulk procurement scenarios where enhanced security justifies additional investment. Electric vehicle compatibility considerations increasingly shape Custom Trailer Hitch Pins Bulk specifications as automotive manufacturers expand electric and hybrid vehicle production. Electric vehicles present unique towing challenges related to battery range impact, regenerative braking integration, and weight distribution optimization. Hitch pin manufacturers must ensure their Custom Trailer Hitch Pins Bulk products maintain compatibility with lightweight hitch systems designed specifically for electric vehicle platforms, where every gram of weight reduction contributes to extended operating range. This segment currently represents fourteen percent of new hitch inquiries and demonstrates accelerated growth potential as electric vehicle adoption rates climb globally.

Material Diversification Strategies for Custom Trailer Hitch Pins Bulk Applications

Bulk purchasers increasingly specify Custom Trailer Hitch Pins Bulk manufactured from specialized materials addressing specific operational environments. Marine applications demand stainless steel construction resisting saltwater corrosion, while agricultural operations may prioritize zinc-plated mild steel offering cost-effectiveness with adequate durability for seasonal use patterns. Industrial logistics providers operating in extreme climates often specify Custom Trailer Hitch Pins Bulk with advanced coating systems combining multiple protective layers—zinc phosphate base coatings overlaid with powder coating topcoats—delivering maximum corrosion resistance for extended replacement cycles. Aluminum alloy hitch pins represent an emerging Custom Trailer Hitch Pins Bulk category targeting weight-conscious applications where reduced mass improves fuel efficiency or enables increased payload capacity within regulatory weight limits. Advanced aluminum alloys provide strength-to-weight ratios approaching steel while delivering inherent corrosion resistance without additional surface treatments. These lightweight Custom Trailer Hitch Pins Bulk solutions particularly appeal to recreational vehicle manufacturers and retrofit specialists seeking performance optimization. However, aluminum options typically command higher unit costs, making them most economically viable for premium applications rather than general-purpose bulk procurement scenarios.

Copper and brass materials, though less common for standard hitch pin applications, fill specialized niches within Custom Trailer Hitch Pins Bulk product ranges. Brass pins offer excellent corrosion resistance combined with antimicrobial properties valuable in food service trailer applications, while copper-based alloys provide superior electrical conductivity for specialized applications involving grounding requirements. Manufacturing facilities capable of processing diverse material specifications—mild steel, coated steel, aluminum alloys, cold rolled steel, stainless steel, copper, and brass—enable bulk purchasers to consolidate supplier relationships while accessing comprehensive Custom Trailer Hitch Pins Bulk inventories meeting varied application requirements.

Quality Assurance Protocols for Custom Trailer Hitch Pins Bulk Procurement

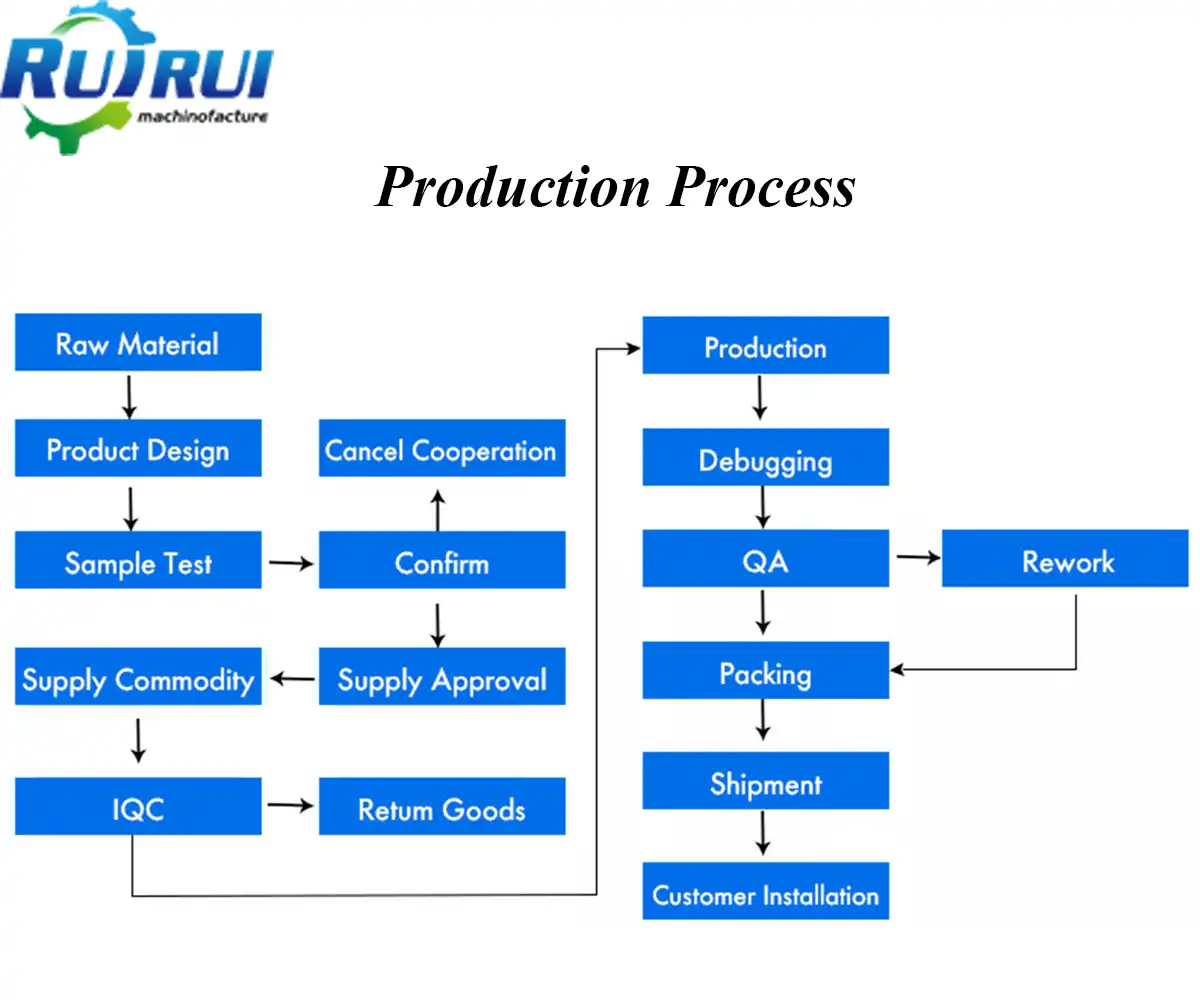

Reputable Custom Trailer Hitch Pins Bulk manufacturers implement comprehensive quality management systems certified to international standards including ISO 9001 quality management, ISO 14001 environmental management, and OHSAS 18001 occupational health and safety frameworks. These certifications demonstrate systematic approaches to quality control, continuous improvement processes, and supply chain sustainability—critical considerations for bulk purchasers establishing long-term supplier partnerships. Quality documentation accompanying Custom Trailer Hitch Pins Bulk orders should include material certifications, dimensional inspection reports, and traceability records linking finished components to raw material batches and production dates. Testing protocols for Custom Trailer Hitch Pins Bulk verify critical performance parameters including tensile strength, shear resistance, and fatigue endurance under cyclic loading conditions simulating real-world towing stresses. Manufacturers employing coordinate measuring machines and automated optical inspection systems achieve consistent dimensional verification across high-volume production runs, ensuring each pin within bulk quantities meets specified tolerances. This quality consistency proves particularly crucial for commercial fleet operators where hitch pin failure could result in cargo loss, vehicle damage, accident liability, or regulatory compliance violations carrying substantial financial and reputational consequences.

Supply Chain Considerations for Custom Trailer Hitch Pins Bulk Orders

Strategic bulk procurement of Custom Trailer Hitch Pins Bulk requires careful evaluation of supplier production capacity, inventory management capabilities, and delivery reliability. Leading manufacturers operate multiple production lines—some facilities maintain eight or more dedicated lines—enabling them to fulfill substantial bulk orders while maintaining rapid turnaround times for replenishment shipments. Annual production capacities exceeding one hundred thirty thousand pieces indicate scale sufficient to support enterprise-level bulk purchasing agreements without compromising delivery schedules or diverting capacity from other customers. Just-in-time delivery capabilities increasingly factor into Custom Trailer Hitch Pins Bulk procurement decisions as purchasers seek to minimize inventory carrying costs while ensuring continuous parts availability. Manufacturers offering flexible packaging options—ranging from individual bagged units through bulk quantities in specialized containers—accommodate diverse distribution models from retail point-of-sale displays to warehouse bulk storage configurations. Professional packaging systems protect Custom Trailer Hitch Pins Bulk components during international shipping, preventing corrosion, physical damage, and dimensional distortion that could render products unusable upon arrival. Geographic distribution networks significantly impact total landed costs for Custom Trailer Hitch Pins Bulk imports. Manufacturers with established logistics partnerships can optimize shipping routes, consolidate freight volumes, and leverage preferential carrier rates that reduce per-unit transportation expenses on bulk orders. For international procurement scenarios, suppliers experienced in export documentation, customs clearance procedures, and compliance with destination country product standards streamline the import process, avoiding costly delays or regulatory complications that inflate effective acquisition costs beyond initial quoted pricing.

Future Demand Drivers for Custom Trailer Hitch Pins Bulk Markets

Recreational vehicle market expansion represents a primary demand catalyst for Custom Trailer Hitch Pins Bulk products. Industry data indicates that recreational vehicle travel contributes over one hundred billion dollars annually to economic activity in major markets, with outdoor recreation participation rates demonstrating sustained growth trajectories. This recreational vehicle popularity directly correlates with increased trailer hitch component demand, as RV owners, boat enthusiasts, and outdoor adventure participants require reliable towing systems utilizing quality hitch pins. The aftermarket sector alone accounts for approximately sixty percent of total hitch component installations, creating substantial opportunities for Custom Trailer Hitch Pins Bulk distributors serving retail and professional installation channels. E-commerce logistics expansion continues reshaping freight transportation patterns, driving increased utilization of trailer systems for last-mile delivery operations. Small package delivery services increasingly deploy trailer-equipped vehicles extending cargo capacity without requiring larger base vehicles. This operational model proliferates across urban and suburban markets where delivery density justifies trailer utilization, creating ongoing demand for replacement Custom Trailer Hitch Pins Bulk components as high-mileage commercial vehicles accelerate normal wear patterns. Fleet maintenance managers prioritize bulk procurement agreements ensuring ready access to replacement parts minimizing vehicle downtime that directly impacts service delivery capabilities and operational profitability.

Emerging Market Opportunities for Custom Trailer Hitch Pins Bulk Suppliers

Agricultural sector modernization presents expanding opportunities for Custom Trailer Hitch Pins Bulk sales as mechanization levels increase globally. Farm operations utilize extensive trailer fleets for equipment transport, harvest logistics, and supply distribution, generating consistent demand for replacement hitch components subjected to harsh operating conditions including dust, moisture, chemical exposure, and heavy loading cycles. Agricultural equipment dealers and farm cooperatives represent potential bulk distribution channels where partnerships with Custom Trailer Hitch Pins Bulk manufacturers enable localized inventory positioning serving regional farming communities. Construction industry activity levels correlate strongly with Custom Trailer Hitch Pins Bulk demand patterns. Construction companies operate diverse trailer assets including equipment haulers, material transport trailers, and mobile office units, all requiring periodic hitch component replacement due to intensive use patterns and demanding operational environments. Heavy-duty construction applications often specify larger diameter hitch pins with enhanced load ratings, creating premium product segments within Custom Trailer Hitch Pins Bulk portfolios. Establishing distribution relationships with construction equipment suppliers and industrial tool distributors provides market access to this significant commercial segment characterized by high-volume consumption and preference for reliable supplier partnerships.

Military and defense applications represent specialized but substantial Custom Trailer Hitch Pins Bulk market segments requiring products meeting rigorous military specifications and quality standards. Defense logistics operations utilize extensive trailer systems for equipment transport, field operations support, and expeditionary deployments where component reliability proves mission-critical. Military procurement contracts often specify domestic production requirements, material traceability, and comprehensive quality documentation—capabilities that established manufacturers with appropriate certifications and production controls can readily satisfy. These contracts typically involve substantial unit quantities under long-term framework agreements providing stable demand visibility supporting production planning and capacity investment decisions.

Competitive Advantages in Custom Trailer Hitch Pins Bulk Manufacturing

Vertical integration strategies enable leading Custom Trailer Hitch Pins Bulk manufacturers to control quality, optimize production costs, and respond flexibly to market demand fluctuations. Facilities incorporating raw material processing, component fabrication, surface treatment, and final assembly operations under unified management achieve superior quality consistency while eliminating coordination delays and markup layers associated with outsourced process steps. This operational model particularly benefits bulk purchasers through competitive pricing structures reflecting actual production costs rather than aggregated supplier margins, while ensuring responsive customer service unencumbered by multi-party coordination requirements. Research and development capabilities distinguish premium Custom Trailer Hitch Pins Bulk suppliers from commodity manufacturers focused solely on existing product replication. Manufacturers investing in product innovation develop proprietary hitch pin designs offering performance advantages including enhanced corrosion resistance, simplified installation procedures, or weight reduction benefits. These differentiated products command premium pricing in specialized applications while establishing brand recognition supporting broader market positioning. Original equipment manufacturer partnerships often emerge from demonstrated innovation capabilities, as vehicle and trailer manufacturers seek component suppliers capable of collaborative product development addressing evolving technical requirements and regulatory standards.

Customization Services Enhancing Custom Trailer Hitch Pins Bulk Value Propositions

Comprehensive customization capabilities expand addressable markets for Custom Trailer Hitch Pins Bulk manufacturers by accommodating specialized application requirements that standardized products cannot satisfy. Custom engineering services enable development of hitch pins with unique dimensions, materials, or feature combinations matching specific customer requirements ranging from proprietary trailer designs through specialized industrial applications. Prototype development capabilities support iterative design refinement ensuring final products meet all functional requirements before committing to bulk production quantities, reducing implementation risks for customers developing new products or systems incorporating custom hitch components. Private label manufacturing services allow distributors and equipment manufacturers to market Custom Trailer Hitch Pins Bulk under proprietary brand identities without investing in production infrastructure. This business model enables partners to maintain brand consistency across product portfolios while leveraging manufacturer expertise in component production, quality assurance, and supply chain management. Private label agreements typically involve substantial minimum order quantities aligning with economies of scale in production setup and inventory management, making Custom Trailer Hitch Pins Bulk products particularly suitable for this arrangement given typical purchase volumes in distribution and OEM channels.

Technical support services differentiate professional-grade Custom Trailer Hitch Pins Bulk suppliers from purely transactional vendors. Application engineering assistance helps customers select appropriate hitch pin specifications matching their specific towing requirements, ensuring optimal safety factors while avoiding over-specification that unnecessarily inflates component costs. Installation guidance documentation and training resources support proper field application, reducing warranty claims and customer dissatisfaction resulting from improper installation rather than product deficiencies. After-sales support including responsive customer service, expedited replacement shipments for defective components, and proactive quality issue resolution build customer loyalty supporting long-term business relationships that transcend individual transactions.

Sustainability Considerations in Custom Trailer Hitch Pins Bulk Production

Environmental management systems increasingly influence Custom Trailer Hitch Pins Bulk manufacturing operations as sustainability considerations gain prominence in corporate procurement policies. ISO 14001 certified manufacturers demonstrate systematic approaches to environmental impact reduction including energy efficiency improvements, waste stream minimization, and responsible chemical management in surface treatment processes. Green supply chain certifications validate comprehensive sustainability practices extending beyond individual facility operations to encompass raw material sourcing, transportation logistics, and end-of-life product management considerations. These credentials appeal to environmentally conscious bulk purchasers implementing sustainability requirements within supplier evaluation and selection processes. Material recycling capabilities contribute to Custom Trailer Hitch Pins Bulk sustainability profiles. Steel-based hitch pins exhibit excellent recyclability characteristics, with scrap metal from production processes readily reintegrated into steelmaking operations rather than contributing to landfill waste. Manufacturers implementing closed-loop material management systems minimize raw material consumption while reducing disposal costs and environmental footprints. Some facilities achieve zero-waste-to-landfill status through comprehensive recycling programs covering not only primary production materials but also packaging components, cutting fluids, and auxiliary supplies utilized throughout manufacturing operations.

Regulatory Compliance Supporting Custom Trailer Hitch Pins Bulk Market Access

Product safety regulations governing trailer hitch components vary internationally, requiring Custom Trailer Hitch Pins Bulk manufacturers serving global markets to maintain familiarity with diverse regulatory frameworks and certification requirements. North American markets operate under Society of Automotive Engineers standards and Department of Transportation regulations establishing minimum performance criteria for towing components. European markets enforce different technical standards under unified type approval systems requiring conformity assessments before products can be legally marketed. Asian markets present additional regulatory considerations with country-specific standards and certification processes. Manufacturers capable of producing Custom Trailer Hitch Pins Bulk meeting multiple international standards enable bulk purchasers to consolidate global sourcing while ensuring regulatory compliance across diverse market jurisdictions. Occupational health and safety certifications including OHSAS 18001 compliance demonstrate manufacturer commitments to worker safety and operational excellence. These management system standards reduce risks of production disruptions due to workplace incidents while ensuring consistent product quality through stable, well-managed production environments. Bulk purchasers establishing long-term supply relationships benefit from supplier operational stability, as facilities maintaining high safety standards typically exhibit lower employee turnover, superior quality metrics, and greater reliability in meeting delivery commitments—all critical factors in maintaining uninterrupted parts availability supporting customer operations.

Quality certifications specific to automotive and transportation industries, including IATF 16949 automotive quality management systems, establish even more rigorous process control requirements applicable to Custom Trailer Hitch Pins Bulk destined for original equipment manufacturer channels. These demanding standards require advanced quality planning methodologies, failure mode and effects analysis, statistical process control, and comprehensive measurement system validation ensuring that every component produced meets exacting specifications. While not all Custom Trailer Hitch Pins Bulk applications require this certification level, its presence signals manufacturing capabilities and quality consciousness that benefit bulk purchasers across all market segments.

Conclusion

Custom Trailer Hitch Pins Bulk markets demonstrate robust growth prospects driven by recreational vehicle expansion, logistics evolution, and technological advancement across towing systems.

Cooperate With Qingdao RUIRUI Machinary Co., LTD.

Seeking a trusted China Custom Trailer Hitch Pins Bulk manufacturer who delivers consistent quality across substantial order volumes? Qingdao RUIRUI Machinery Co., LTD., established in 2016 and located in Qingdao, Shandong, China, specializes as both a China Custom Trailer Hitch Pins Bulk factory and China Custom Trailer Hitch Pins Bulk supplier offering comprehensive metal fabrication capabilities. Our expertise encompasses progressive stamping, deep drawing, CNC machining, and laser cutting, combined with advanced surface treatments including powder coating, plating, anodizing, and electrophoresis—ensuring your Custom Trailer Hitch Pins Bulk orders receive optimal processing for demanding applications.

As a certified China Custom Trailer Hitch Pins Bulk wholesale provider maintaining ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001 certifications, we deliver High Quality Custom Trailer Hitch Pins Bulk through our eight production lines generating annual output exceeding 130,000 pieces. Our experienced R&D team provides OEM support for custom specifications, while professional packaging and short delivery timelines ensure your Custom Trailer Hitch Pins Bulk for sale arrives safely and punctually. We process diverse materials including mild steel, stainless steel, aluminum alloys, copper, and brass, with competitive Custom Trailer Hitch Pins Bulk price structures reflecting our efficient operations. Contact us at info@qdkshd.com to discuss your bulk procurement requirements and discover how our technical support and after-sales service commitment can strengthen your supply chain.

References

1. "Vehicle Trailer Hitch Market Size Analysis and Growth Projections," Global Growth Insights Research Division, Market Research Report Series, 2025.

2. "Trailer Hitch Industry Dynamics: Manufacturing Trends and Regional Demand Patterns," Cognitive Market Research, Automotive Components Analysis, 2024.

3. "Advanced Manufacturing Technologies in Metal Stamping and Fabrication," Market Intelligence Research Group, Industrial Engineering Studies, 2024.

4. "Recreational Vehicle Market Impact on Towing Accessories Demand," Business Research Insights, Consumer Products Division, 2025.

5. "Quality Management Systems and Certification Standards in Automotive Supply Chains," International Standards Organization, Technical Publication Series, 2024.

Send Inquiry

You may like