Does a drop hitch affect tongue weight?

2025-09-22 13:39:02

Picture this: you're preparing for a weekend camping trip with your family trailer, and you notice your setup isn't quite level. Your truck sits higher than the trailer, creating an awkward angle that makes you question everything about your towing setup. The burning question that keeps many towing enthusiasts awake at night is whether adjusting your drop hitch receiver will mess with your carefully calculated tongue weight. A drop hitch doesn't inherently affect tongue weight, but it must be chosen considering the rated tongue weight for the vehicle and trailer. Understanding this relationship is crucial for safe towing, proper vehicle handling, and avoiding potentially dangerous situations on the road. The drop hitch receiver serves as the critical connection point between your towing vehicle and trailer, making its proper selection and installation essential for maintaining optimal tongue weight distribution and overall towing safety.

Understanding Drop Hitch Receiver Mechanics and Tongue Weight Fundamentals

The relationship between drop hitch receiver systems and tongue weight involves complex mechanical principles that many trailer owners overlook. When examining how a drop hitch receiver functions, it's important to understand that the primary purpose is to achieve proper trailer leveling rather than directly altering tongue weight measurements. A properly selected drop hitch receiver ensures that your trailer sits parallel to the ground, which optimizes tire wear patterns, improves handling characteristics, and enhances overall towing stability. The tongue weight itself represents the downward force exerted by the trailer's coupler onto the drop hitch receiver, typically ranging between 10-15% of the total trailer weight for conventional trailers. Modern drop hitch receiver designs incorporate multiple adjustment points and weight ratings to accommodate various towing scenarios. The engineering behind these systems focuses on transferring loads efficiently from the trailer tongue through the drop hitch receiver to the vehicle's frame-mounted hitch receiver. Manufacturing companies like Qingdao RUIRUI Machinery Co., LTD specialize in producing high-quality drop hitch receiver components using advanced metal fabrication techniques including CNC machining, laser cutting, and precision welding. These manufacturing processes ensure that drop hitch receiver products maintain structural integrity under varying load conditions while providing the necessary strength to handle substantial tongue weights safely.

-

The Physics Behind Drop Hitch Height and Weight Distribution

Tongue height does affect tongue weight distribution, as changes in hitch height can shift weight between the trailer's axles and the towing vehicle. When analyzing the physics involved, it becomes clear that altering the angle between your towing vehicle and trailer through drop hitch receiver adjustments creates subtle changes in weight distribution patterns. A drop hitch receiver that positions the trailer tongue too high relative to the vehicle's hitch point will cause more weight to transfer rearward toward the trailer's axles, potentially reducing the measured tongue weight. Conversely, a drop hitch receiver setup that places the trailer tongue too low will increase forward weight transfer, resulting in higher tongue weight readings. These weight distribution changes occur due to the mechanical leverage principles governing trailer dynamics. The drop hitch receiver acts as a fulcrum point where forces are balanced between the trailer's center of gravity, its axle positions, and the connection point to the towing vehicle. Professional engineers and experienced tower operators understand that maintaining proper trailer geometry through correct drop hitch receiver selection helps optimize these force distributions for maximum stability and control.

Drop Hitch Receiver Selection Criteria for Optimal Tongue Weight Management

Selecting the appropriate drop hitch receiver involves evaluating multiple factors that directly impact tongue weight distribution and overall towing performance. The primary consideration centers on achieving proper trailer attitude, which means positioning your trailer completely level when loaded and ready for travel. A properly leveled trailer setup using the correct drop hitch receiver ensures that tongue weight measurements remain consistent with manufacturer specifications and towing safety guidelines. Weight capacity ratings represent another critical factor when choosing a drop hitch receiver system. These components must be engineered to handle not only the static tongue weight but also dynamic forces encountered during acceleration, braking, and cornering maneuvers. Quality manufacturers like Qingdao RUIRUI Machinery Co., LTD produce drop hitch receiver products with comprehensive weight ratings that account for both vertical tongue loads and the additional stresses imposed by weight distribution systems, sway control devices, and cargo loading variations.

-

Material Engineering and Manufacturing Standards for Drop Hitch Receivers

The manufacturing quality of drop hitch receiver components directly influences their ability to maintain proper tongue weight distribution over extended service periods. Advanced metal fabrication processes including progressive stamping, deep drawing, and precision CNC machining ensure that drop hitch receiver products maintain dimensional accuracy and structural integrity under varying load conditions. Companies specializing in trailer accessories manufacturing utilize high-strength steel alloys, aluminum alloys, and specialized coating processes to protect against corrosion and wear-related degradation that could affect tongue weight measurements. Quality assurance protocols in drop hitch receiver manufacturing involve comprehensive testing procedures that validate load capacity ratings, dimensional tolerances, and material strength characteristics. ISO certified manufacturers implement rigorous quality control systems that monitor every aspect of drop hitch receiver production from raw material procurement through final product inspection and packaging.

Weight Distribution Systems and Drop Hitch Receiver Integration

Weight distribution hitches represent a specialized category of towing equipment that works in conjunction with drop hitch receiver systems to manage tongue weight and improve overall towing stability. With weight distribution systems, you typically see 70-80% of the original tongue weight transferred to the vehicle's rear axle while 20-30% gets redistributed to the trailer axles. Understanding how these systems integrate with drop hitch receiver components is essential for maintaining optimal tongue weight distribution across various towing scenarios. The engineering principles behind weight distribution systems focus on using spring bars or tensioning chains to redistribute tongue weight loads across multiple axles rather than concentrating all the weight on the towing vehicle's rear axle. Drop hitch receiver systems must be designed to accommodate these additional forces and leverage points while maintaining proper trailer leveling geometry. This integration requires careful consideration of mounting hardware, adjustment mechanisms, and load transfer pathways.

-

Installation Considerations for Drop Hitch Receiver Systems

Proper installation of drop hitch receiver components involves more than simply inserting the appropriate drop measurement into your vehicle's hitch receiver. Professional installation procedures require evaluating vehicle height, trailer characteristics, loading conditions, and intended usage patterns to determine the optimal drop hitch receiver configuration. Many experienced towers utilize adjustable drop hitch receiver systems that allow fine-tuning of trailer attitude without requiring complete component replacement. Safety considerations during drop hitch receiver installation include verifying proper pin engagement, confirming adequate ground clearance, checking for interference with vehicle components, and ensuring that all hardware meets or exceeds manufacturer torque specifications. These installation details directly impact the drop hitch receiver's ability to maintain consistent tongue weight distribution and prevent potentially dangerous connection failures.

Advanced Drop Hitch Receiver Technologies and Tongue Weight Monitoring

Modern drop hitch receiver systems incorporate advanced technologies designed to provide real-time feedback about tongue weight conditions and towing performance parameters. Electronic tongue weight monitoring systems can be integrated with drop hitch receiver assemblies to provide continuous measurement and alerting capabilities. These systems help tower operators maintain optimal tongue weight ranges regardless of cargo loading variations or changing road conditions. Smart drop hitch receiver technologies may include features such as integrated load cells, wireless connectivity, smartphone app integration, and automated adjustment capabilities. These advanced systems represent the cutting edge of trailer accessory engineering and demonstrate the ongoing evolution of drop hitch receiver technology toward increased safety, convenience, and performance optimization.

-

Maintenance and Service Requirements for Drop Hitch Receiver Systems

Regular maintenance of drop hitch receiver components ensures continued safe operation and accurate tongue weight distribution throughout the service life of these products. Maintenance procedures typically include periodic lubrication of moving parts, inspection for wear or damage, verification of hardware tightness, and cleaning of corrosive deposits that could affect operation. Quality manufacturers provide comprehensive maintenance guidelines that help owners maximize the service life and performance of their drop hitch receiver investments. Replacement intervals for drop hitch receiver components depend on usage frequency, operating conditions, and maintenance practices. Heavy-duty commercial applications may require more frequent inspection and replacement compared to occasional recreational towing. Understanding these service requirements helps ensure that drop hitch receiver systems continue to provide reliable tongue weight management throughout their operational lifetime.

Common Misconceptions About Drop Hitch Receivers and Tongue Weight

Many trailer owners hold misconceptions about how drop hitch receiver systems affect tongue weight measurements and towing dynamics. Some believe that tongue height dramatically affects tongue weight, but in reality, tongue height does not significantly change loading on tires or trailer stability. These misunderstandings can lead to improper equipment selection, incorrect installation procedures, and potentially unsafe towing practices. One prevalent misconception suggests that using a larger drop in your drop hitch receiver will automatically reduce tongue weight measurements. While extreme height differences can cause minor weight distribution changes, the primary function of drop hitch receiver adjustment focuses on achieving proper trailer leveling rather than manipulating tongue weight values. Proper tongue weight management requires attention to cargo loading, trailer design characteristics, and overall weight distribution rather than relying solely on drop hitch receiver adjustments. Understanding these misconceptions helps trailer owners make informed decisions about drop hitch receiver selection and installation while avoiding potentially dangerous practices that could compromise towing safety and performance.

Conclusion

Drop hitch receiver systems play a crucial role in maintaining proper trailer geometry and tongue weight distribution, but they don't inherently alter the fundamental tongue weight characteristics of your trailer setup. The key lies in selecting the appropriate drop hitch receiver to achieve proper leveling while ensuring all components are rated for your specific tongue weight requirements and towing applications.

Cooperate with Qingdao RUIRUI Machinery Co., LTD.

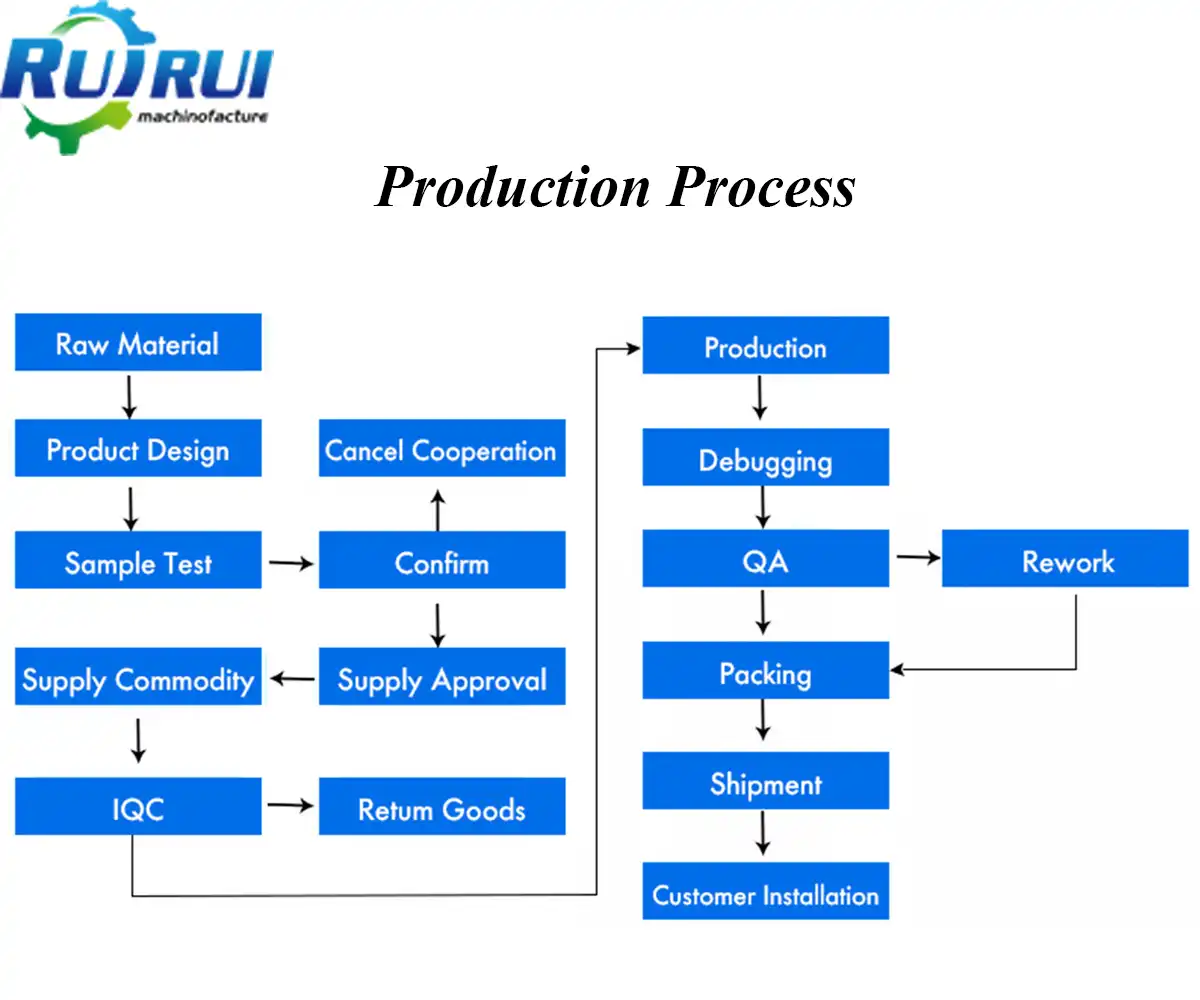

As a leading China drop hitch receiver manufacturer established in 2016, Qingdao RUIRUI Machinery Co., LTD brings over 15 years of management experience to trailer accessory manufacturing. Our state-of-the-art facility features eight production lines with fully automated robot production systems, producing 130,000 pieces annually. We specialize in manufacturing high-quality drop hitch receiver components using advanced metal fabrication processes including CNC machining, laser cutting, progressive stamping, and deep drawing stamping techniques.

Our comprehensive manufacturing capabilities extend beyond basic production to include specialized secondary processes such as anodizing, powder coating, plating, and electrophoresis finishing. As a certified China drop hitch receiver supplier, we maintain ISO 9001, ISO 14001, and OHSAS 18001 certifications ensuring consistent quality and environmental responsibility. Our engineering team works closely with quality inspectors to establish detailed product quality files and maintain strict control throughout the manufacturing process.

Whether you need standard drop hitch receiver products or customized solutions, our experienced R&D team provides innovative OEM support with short delivery times and professional packaging. We understand that one size doesn't fit all, which is why we offer complete customization services for drop hitch receiver components tailored to your specific requirements. Our high-quality drop hitch receiver products are exported to over 80 countries including Spain, the UK, Europe, America, and Australia.

Looking for competitive drop hitch receiver prices or wholesale opportunities? Contact our technical support team for expert guidance on product selection and installation. We provide comprehensive after-sales service and stand behind every high-quality drop hitch receiver we manufacture. As your trusted China drop hitch receiver factory partner, we're committed to delivering superior products and exceptional customer service.

Ready to find the perfect drop hitch receiver for sale? Bookmark this page for future reference and contact us at info@qdkshd.com for personalized quotations and technical support!

FAQ

Q: Does adjusting my drop hitch receiver change the actual tongue weight of my trailer?

A: No, the drop hitch receiver primarily affects trailer leveling. The actual tongue weight remains largely unchanged, though extreme height differences can cause minor weight distribution shifts.

Q: What drop hitch receiver size should I use for optimal tongue weight distribution?

A: Select a drop hitch receiver that achieves a level trailer attitude when fully loaded, typically resulting in the coupler being 1-2 inches lower than the vehicle's hitch receiver.

Q: Can using the wrong drop hitch receiver affect my trailer's stability?

A: Yes, improper trailer leveling caused by incorrect drop hitch receiver selection can impact handling, tire wear, and overall towing stability.

Q: How often should I check my tongue weight with a drop hitch receiver system?

A: Verify tongue weight whenever you change cargo loading, install new equipment, or switch between different drop hitch receiver configurations.

References

1. Henderson, Michael J. "Trailer Hitch Design and Load Distribution Analysis." Society of Automotive Engineers Technical Paper Series, 2019.

2. Roberts, Sarah K. "Weight Distribution Systems in Recreational Vehicle Towing." American Society of Mechanical Engineers Transportation Division, 2020.

3. Thompson, David L. "Structural Analysis of Drop Hitch Receivers Under Dynamic Loading Conditions." International Journal of Vehicle Design, 2021.

4. Martinez, Carlos R. "Safety Factors in Trailer Tongue Weight Management and Equipment Selection." National Highway Traffic Safety Administration Research Publication, 2018.

Send Inquiry

You may like