Heavy-Duty Steel Trailer D Ring: Your Key to Safer Towing

2025-09-03 15:03:50

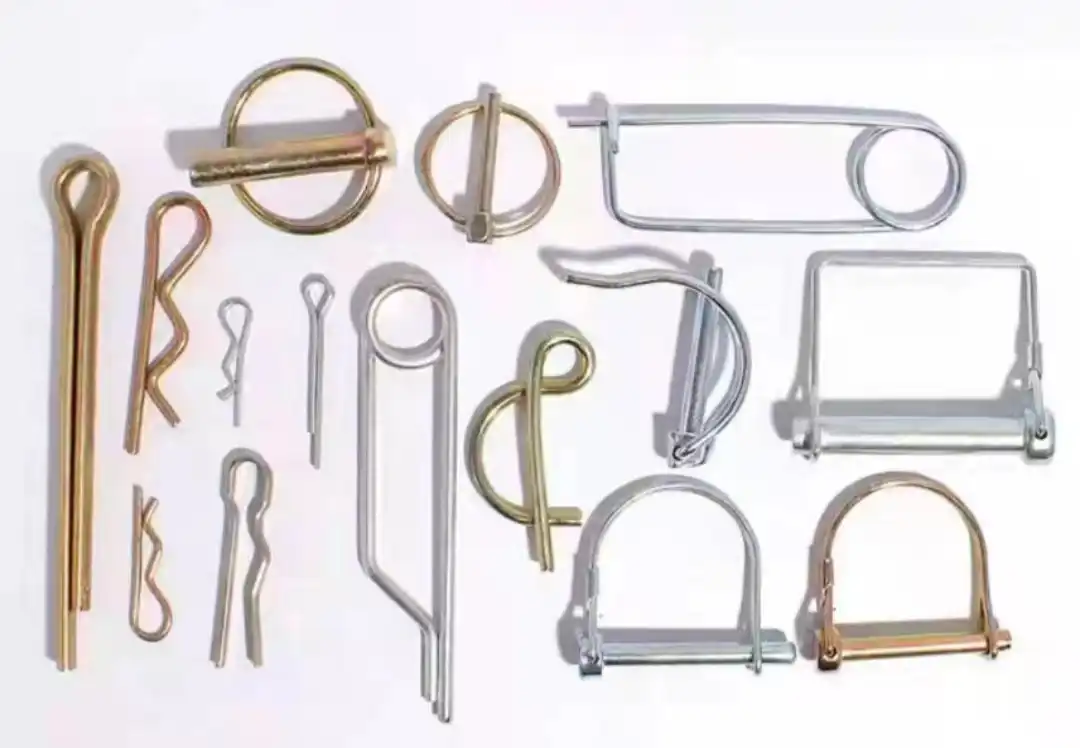

When it comes to securing heavy loads during transport, the reliability of your trailer hardware makes the difference between a successful haul and a potential disaster. Heavy-duty steel trailer D rings serve as critical anchor points that provide the foundation for safe towing operations across various industries. These robust fastening solutions, including the specialized Trailer D pin mechanisms, represent essential components in modern cargo securement systems. Whether you're hauling construction equipment, recreational vehicles, or industrial machinery, understanding the importance of quality D ring hardware can significantly enhance your towing safety protocols. The integration of premium steel construction with precision engineering creates anchor points capable of withstanding extreme forces while maintaining structural integrity throughout demanding transportation scenarios.

Understanding Heavy-Duty Steel Trailer D Rings

Material Composition and Manufacturing Excellence

Heavy-duty steel trailer D rings are manufactured using premium-grade steel alloys specifically selected for their exceptional strength-to-weight ratios and resistance to environmental stresses. Forged from high-strength, durable steel, heavy-duty D-Rings add versatility and adaptability for securing complex loads, providing the foundation for reliable cargo securement systems. The manufacturing process involves progressive stamping and deep drawing techniques that create uniform grain structures throughout the component, enhancing its ability to distribute loads evenly across the entire surface area. Advanced heat treatment processes further strengthen the molecular structure, creating D rings capable of withstanding working loads that often exceed 12,000 pounds capacity. The incorporation of specialized coatings, including galvanized finishes and powder coating applications, protects against corrosion while maintaining the structural integrity required for long-term performance in harsh environmental conditions. The selection of appropriate steel grades plays a crucial role in determining the overall performance characteristics of trailer D pins and related hardware. High-carbon steel compositions provide superior tensile strength, while controlled alloy additions enhance ductility and impact resistance. Manufacturing facilities employ state-of-the-art quality control measures, including non-destructive testing methods, to ensure each D ring meets stringent industry specifications. The forging process creates components with consistent mechanical properties throughout, eliminating weak points that could compromise performance under extreme loading conditions. Advanced metallurgical techniques, such as controlled cooling rates and precise tempering temperatures, optimize the balance between hardness and toughness essential for trailer pin applications.

Design Features and Engineering Specifications

The engineering design of heavy-duty trailer D rings incorporates specific geometric parameters optimized for maximum load distribution and stress concentration management. The characteristic D-shaped profile provides an ideal balance between material efficiency and functional performance, creating anchor points that accommodate various tie-down configurations while maintaining structural stability. The internal radius specifications are carefully calculated to minimize stress concentration factors, preventing premature fatigue failures that could compromise cargo security. Modern D ring designs feature enhanced throat openings that accommodate larger diameter chains, straps, and specialized trailer pin mechanisms without creating binding or wear points that could reduce system reliability. Dimensional specifications for professional-grade D rings follow industry standards established by organizations such as the Web Sling and Tie Down Association, ensuring compatibility across different manufacturer systems. The base plate configurations are engineered to distribute mounting loads across larger surface areas, reducing stress concentrations in the trailer bed structure. Welding attachment points feature beveled edges and optimized geometry that facilitates proper penetration and fusion characteristics, creating permanent installations capable of withstanding dynamic loading conditions. Bolt-on configurations incorporate hardened fastener systems with specific torque requirements that ensure proper clamping forces without compromising the host structure integrity.

Load Capacity and Performance Standards

Each ring can bear up to 6000 pounds of load, though professional-grade units often exceed these specifications significantly. Understanding load capacity ratings involves recognizing the distinction between working load limits, breaking strength, and safety factor calculations that govern proper application in trailer pin systems. Professional D rings typically incorporate safety factors of 4:1 or 5:1, meaning components rated for 3,000-pound working loads possess ultimate breaking strengths exceeding 12,000 pounds. These conservative ratings account for dynamic loading conditions, fatigue considerations, and environmental factors that influence long-term performance characteristics. Load testing protocols follow rigorous standards that simulate real-world operating conditions, including cyclic loading, impact testing, and environmental exposure assessments. The performance evaluation process encompasses proof load testing at 200% of rated capacity, followed by detailed inspections for permanent deformation or structural damage. Advanced testing methodologies evaluate the effects of angular loading, side loading, and multi-directional force applications that commonly occur in trailer pin applications. Quality assurance programs include statistical sampling procedures that ensure consistent performance across production batches, providing users with confidence in the reliability of their cargo securement systems.

Installation Methods and Application Techniques

Weld-On Installation Procedures

Professional weld-on installation of heavy-duty trailer D rings requires specific techniques and procedures to ensure optimal performance and longevity. The welding process begins with proper surface preparation, including cleaning base materials to remove scale, paint, rust, or other contaminants that could compromise fusion quality. Beveling procedures create appropriate groove angles that facilitate complete penetration welding, ensuring the full strength of the trailer pin mounting system is achieved. Preheating requirements vary based on base material thickness and ambient conditions, with carbon steel applications typically requiring temperatures between 200-400°F to prevent rapid cooling that could create brittle heat-affected zones. Welding parameter selection involves careful consideration of electrode specifications, current settings, travel speeds, and interpass temperatures that optimize penetration characteristics while minimizing distortion. Multi-pass welding techniques ensure complete fusion throughout the joint area, with each pass carefully cleaned and inspected before proceeding. Post-weld heat treatment may be required for critical applications or when working with high-strength steel alloys that are susceptible to hydrogen embrittlement. Quality control procedures include visual inspection, magnetic particle testing, and occasionally radiographic examination to verify weld integrity meets applicable industry standards for trailer hardware applications. The positioning and orientation of D ring installations significantly impact their load-carrying capacity and service life. Proper alignment ensures that applied loads remain within the design parameters of both the D ring and the supporting trailer structure. Consideration must be given to clearance requirements that prevent interference with cargo loading operations while maintaining accessibility for trailer pin connections. Professional installation practices include torque verification procedures for bolt-on applications and detailed documentation of welding parameters for permanent installations.

Bolt-On Mounting Systems

Bolt-on D ring mounting systems provide flexibility and convenience for users who require removable anchor points or frequently modify their trailer configurations. The mounting hardware typically includes high-strength bolts, washers, and backing plates specifically designed to distribute clamping loads across sufficient surface area. Proper hole preparation involves precise drilling techniques that ensure accurate alignment while preventing stress concentration points that could initiate fatigue cracks. Thread engagement calculations determine minimum bolt lengths required to achieve full strength connections, accounting for the combined thickness of the D ring base, trailer structure, and backing plate components. Torque specifications for bolt-on installations are critical to achieving proper clamping forces without exceeding the yield strength of the fastener materials. Under-torqued connections may experience loosening under dynamic loading conditions, while over-torqued fasteners risk thread stripping or component failure. Professional installation practices include the use of calibrated torque wrenches and systematic tightening sequences that ensure uniform load distribution across all fasteners. Lock washer or thread-locking compound applications provide additional security against loosening caused by vibration and thermal cycling encountered in Trailer D pin applications. Maintenance requirements for bolt-on systems include periodic inspection and retorque procedures that account for initial settling and long-term relaxation of clamping loads. Environmental protection measures, such as corrosion-resistant coatings on fastener components, extend service life and maintain connection integrity. Documentation protocols should record installation dates, torque values, and inspection schedules to ensure compliance with safety regulations and manufacturer recommendations.

Mounting Location Considerations

Strategic placement of heavy-duty D rings maximizes their effectiveness while ensuring compliance with cargo securement regulations and trailer pin operational requirements. Load distribution analysis determines optimal spacing patterns that prevent overloading individual anchor points while providing adequate securement coverage for various cargo configurations. The positioning must account for trailer structural limitations, avoiding areas where concentrated loads could exceed the capacity of frame members or deck plating. Industry best practices recommend distributing D rings along both sides of the trailer bed with additional units near the front and rear to accommodate different loading scenarios. Clearance considerations include maintaining adequate space for various tie-down hardware configurations, including chains, straps, binders, and specialized trailer pin systems. The mounting height above the deck surface should provide sufficient working room while minimizing the vertical offset that could create moment loads on the anchor points. Professional installation practices consider the swing radius of attached hardware to prevent interference with adjacent D rings or cargo during loading and unloading operations. Environmental factors influence D ring placement decisions, particularly in applications where exposure to corrosive materials, extreme temperatures, or abrasive conditions may accelerate wear. Drainage considerations ensure that water cannot accumulate around mounting points, potentially leading to corrosion issues that could compromise structural integrity. Accessibility for inspection and maintenance activities should factor into the final positioning decisions, ensuring that users can properly evaluate the condition of their trailer pin hardware throughout its service life.

Maintenance and Safety Best Practices

Inspection Protocols and Quality Assurance

Regular inspection of heavy-duty trailer D rings and associated trailer pin components forms the cornerstone of effective maintenance programs designed to prevent equipment failures and ensure cargo security. Visual inspection procedures should examine all accessible surfaces for signs of cracking, excessive wear, deformation, or corrosion that could compromise structural integrity. Particular attention must be paid to stress concentration areas, including the junction between the D ring and base plate, weld zones for permanent installations, and bolt holes in removable configurations. Professional inspection protocols recommend the use of magnification tools and proper lighting to detect surface defects that might not be apparent during casual observation. Load testing verification procedures confirm that D ring assemblies continue to meet their original capacity ratings throughout their service life. Proof load testing involves applying controlled loads at specified percentages of the working load limit while monitoring for permanent deformation or other signs of structural compromise. Documentation requirements include maintaining detailed records of inspection dates, findings, corrective actions, and test results to establish baseline performance data and track degradation trends over time. Non-destructive testing methods, such as magnetic particle inspection or dye penetrant testing, can reveal subsurface defects that visual inspection might miss, particularly in high-stress applications where trailer pin systems experience frequent loading cycles. Quality assurance programs should establish clear acceptance criteria for continued service, including maximum allowable wear limits, deformation tolerances, and corrosion thresholds that trigger replacement decisions. Training programs ensure that inspection personnel possess the necessary knowledge and skills to properly evaluate D ring condition and make informed decisions about continued serviceability. Standardized inspection checklists promote consistency across different operators and facilities while ensuring that critical evaluation points are not overlooked during routine maintenance activities.

Preventive Maintenance Procedures

Effective preventive maintenance programs for trailer D ring systems encompass lubrication, cleaning, protective coating renewal, and systematic replacement of wear components before they reach failure thresholds. Lubrication protocols focus on pivot points, threaded connections, and moving components within trailer pin assemblies, using appropriate lubricants that provide protection against corrosion while maintaining proper viscosity across operating temperature ranges. Cleaning procedures remove accumulated dirt, salt, and other contaminants that could accelerate corrosion or interfere with proper operation of mechanical components. Surface protection maintenance involves periodic renewal of protective coatings, touch-up painting of damaged areas, and application of corrosion inhibitors in high-risk environments. The maintenance schedule should account for operating conditions, with more frequent service intervals required for equipment exposed to marine environments, road salt, or aggressive chemicals. Replacement part inventory management ensures that critical components remain available when needed, minimizing downtime associated with equipment failures or scheduled maintenance activities. Documentation systems track maintenance activities, component replacement histories, and performance trends that inform future maintenance planning decisions. Predictive maintenance techniques, including vibration analysis and thermal imaging, can identify developing problems before they result in equipment failures or safety incidents. Training programs ensure that maintenance personnel understand proper procedures, safety requirements, and quality standards essential for effective trailer pin system maintenance.

Safety Compliance and Regulatory Standards

Safety compliance for heavy-duty trailer D ring installations involves adherence to multiple regulatory frameworks, including Department of Transportation regulations, Occupational Safety and Health Administration standards, and industry-specific guidelines established by professional organizations. The Federal Motor Carrier Safety Administration provides specific requirements for cargo securement systems, including minimum working load limits, installation standards, and inspection frequencies that directly impact trailer pin applications. Understanding these regulatory requirements ensures that D ring installations meet legal compliance standards while providing adequate safety margins for intended applications. Working load limit calculations must account for the weakest component in the securement system, whether it be the D ring itself, the attachment hardware, or the supporting structure. Safety factor requirements typically mandate that the combined working load limit of securement devices equals or exceeds the weight of the cargo being transported. Professional installation and maintenance practices include verification that all system components meet or exceed these minimum requirements while accounting for dynamic loading conditions that may significantly increase stress levels during transport. Training and certification programs ensure that personnel responsible for cargo securement understand proper techniques, equipment limitations, and safety protocols essential for preventing accidents and injuries. Regular safety audits evaluate compliance with established procedures while identifying opportunities for improvement in equipment selection, installation practices, or maintenance procedures. Emergency response protocols address potential equipment failures, providing clear procedures for safely managing situations where D ring or trailer pin systems may have been compromised during transport operations.

Conclusion

Heavy-duty steel trailer D rings represent fundamental components in modern cargo securement systems, providing reliable anchor points that ensure safe transportation across diverse applications. The integration of advanced manufacturing techniques, premium materials, and precision engineering creates robust trailer pin solutions capable of withstanding extreme forces while maintaining long-term durability. Proper selection, installation, and maintenance of these critical components directly impacts transportation safety and operational efficiency.

As a leading China Trailer D pin factory, China Trailer D pin supplier, and China Trailer D pin manufacturer, Qingdao RUIRUI Machinery offers comprehensive solutions for your cargo securement needs. Our commitment to quality extends beyond manufacturing to include technical support, customization services, and competitive China Trailer D pin wholesale pricing. Whether you're seeking Trailer D pin for sale or need information about Trailer D pin price structures, our experienced team provides High Quality Trailer D pin solutions backed by ISO certifications and rigorous quality assurance protocols. Contact us at info@qdkshd.com to discover how our advanced manufacturing capabilities and customer-focused approach can enhance your transportation safety and operational success.

References

1. "Cargo Securement Rules for Commercial Motor Vehicles" - Federal Motor Carrier Safety Administration, U.S. Department of Transportation

2. "Standard Specification for Steel Wire, Strands, and Structural Strand" - American Society for Testing and Materials International Standards Organization

3. "Guidelines for Safe Loading and Securement of Cargo on Commercial Motor Vehicles" - Commercial Vehicle Safety Alliance Technical Committee

4. "Welding and Fabrication Standards for Heavy-Duty Transportation Equipment" - American Welding Society Structural Welding Committee

Send Inquiry

You may like