Heavy Duty Trailer Jack: The Unbeatable Choice for Extreme Loads

2025-10-09 15:48:17

Picture this: You're hauling a 12,000-pound load across rough terrain when your standard trailer jack gives way, leaving you stranded with a potentially dangerous situation. This nightmare scenario is exactly why investing in a heavy duty trailer jack isn't just a choice – it's a necessity for anyone serious about heavy-load transportation. When extreme loads demand unwavering support, only the most robust heavy duty trailer jack solutions can deliver the reliability and strength needed to keep your operations running smoothly and safely.

Understanding Heavy Duty Trailer Jack Engineering for Maximum Load Capacity

The foundation of any exceptional heavy duty trailer jack lies in its engineering principles and load-bearing capabilities. Unlike standard jacks designed for lighter applications, heavy duty trailer jack systems are engineered to withstand extreme forces while maintaining structural integrity under the most demanding conditions. These specialized jacks incorporate advanced metallurgy, precision manufacturing, and robust mechanical designs that set them apart from conventional alternatives.

-

Superior Material Construction and Manufacturing Standards

High-performance heavy duty trailer jack units are constructed using premium-grade steel materials that undergo rigorous quality control processes. The steel composition is specifically chosen to provide optimal tensile strength, durability, and resistance to fatigue under repeated loading cycles. RUIRUI's manufacturing facility in Qingdao, China, utilizes advanced CNC machining, laser cutting, and precision welding techniques to ensure each heavy duty trailer jack meets stringent ISO quality standards. The trailer jack foot plate components are manufactured with exceptional attention to detail, incorporating deep drawing stamping and progressive stamping processes that create seamless integration between all mechanical components.

-

Advanced Load Distribution Technology

Modern heavy duty trailer jack designs feature sophisticated load distribution systems that effectively transfer weight across multiple contact points. This technology prevents stress concentration at critical junction points while ensuring uniform load bearing across the entire structure. The trailer jack foot plate serves as a crucial component in this system, providing stable ground contact and preventing sinking in soft terrain conditions.

Heavy Duty Trailer Jack Applications Across Industries

The versatility of heavy duty trailer jack systems extends across numerous industries, each with specific requirements and operational challenges. Understanding these applications helps buyers select the most appropriate jack configuration for their particular needs.

-

Agricultural and Construction Equipment Transport

Agricultural operations frequently require heavy duty trailer jack systems capable of supporting massive implements, harvesting equipment, and grain trailers. Construction sites demand jacks that can handle excavators, bulldozers, and heavy material transport trailers. These applications subject heavy duty trailer jack systems to extreme weight loads, vibration, and harsh environmental conditions. The robust construction of professional-grade jacks ensures reliable performance even when supporting loads exceeding 10,000 pounds. RUIRUI's heavy duty trailer jack products are specifically engineered to meet these demanding requirements through advanced manufacturing processes including anodizing, powder coating, and electrophoresis treatments that provide superior corrosion resistance.

-

Marine and Recreational Vehicle Support

Boat trailers and large recreational vehicles present unique challenges for heavy duty trailer jack systems. Marine environments expose jacks to corrosive salt water, sand, and extreme weather conditions. RV applications require jacks that can provide stable support during extended parking periods while maintaining smooth operation despite exposure to road debris and varying terrain conditions. Premium heavy duty trailer jack units incorporate specialized protective coatings and sealed bearing systems that ensure long-term reliability in these challenging environments.

Technical Specifications and Performance Standards for Heavy Duty Trailer Jacks

Professional buyers require detailed technical information to make informed purchasing decisions. Understanding the key performance metrics and specifications of heavy duty trailer jack systems is essential for selecting the optimal solution for specific applications.

-

Load Capacity and Safety Factor Analysis

Heavy duty trailer jack systems are rated according to their maximum static load capacity, typically ranging from 5,000 to 15,000 pounds for commercial applications. However, the actual working load should never exceed 75% of the rated capacity to maintain appropriate safety margins. The trailer jack foot plate design plays a critical role in load distribution, with larger contact areas providing better stability and reduced ground pressure. RUIRUI manufactures heavy duty trailer jack units with load capacities up to 12,000 pounds, utilizing precision engineering and high-strength steel construction to ensure reliable performance under extreme conditions.

-

Mechanical Operation and Maintenance Requirements

Modern heavy duty trailer jack designs incorporate dual-speed gear systems that provide efficient lifting and lowering operations. These systems typically feature a high-speed mode for rapid travel and a low-speed mode for precise positioning under load. Regular maintenance includes lubrication of gear mechanisms, inspection of the trailer jack foot plate for wear, and verification of structural integrity. RUIRUI's manufacturing process includes comprehensive quality control measures and detailed documentation to ensure each heavy duty trailer jack meets stringent performance standards throughout its operational life.

Selecting the Right Heavy Duty Trailer Jack Configuration

Choosing the appropriate heavy duty trailer jack configuration requires careful consideration of multiple factors including load requirements, operating environment, and installation constraints. Professional buyers must evaluate these parameters to ensure optimal performance and long-term reliability.

-

Direct-Weld vs. Bolt-On Mounting Systems

Heavy duty trailer jack mounting systems fall into two primary categories: direct-weld and bolt-on configurations. Direct-weld systems provide superior strength and rigidity by permanently attaching the jack to the trailer frame structure. These systems are ideal for applications requiring maximum load capacity and structural integrity. Bolt-on systems offer greater flexibility for maintenance and replacement but may have slightly lower load ratings. The choice between mounting systems depends on specific application requirements and maintenance preferences. RUIRUI offers both configurations with customization options to meet unique customer specifications.

-

Electric vs. Manual Operation Options

Heavy duty trailer jack systems are available with either manual crank operation or electric motor drives. Manual systems provide reliable operation without dependence on electrical power but require physical effort for operation. Electric systems offer convenient push-button operation and are particularly beneficial for frequent use applications. The trailer jack foot plate functions identically regardless of the operating system chosen. Electric systems typically include weatherproof controls and overload protection features to ensure safe operation under all conditions.

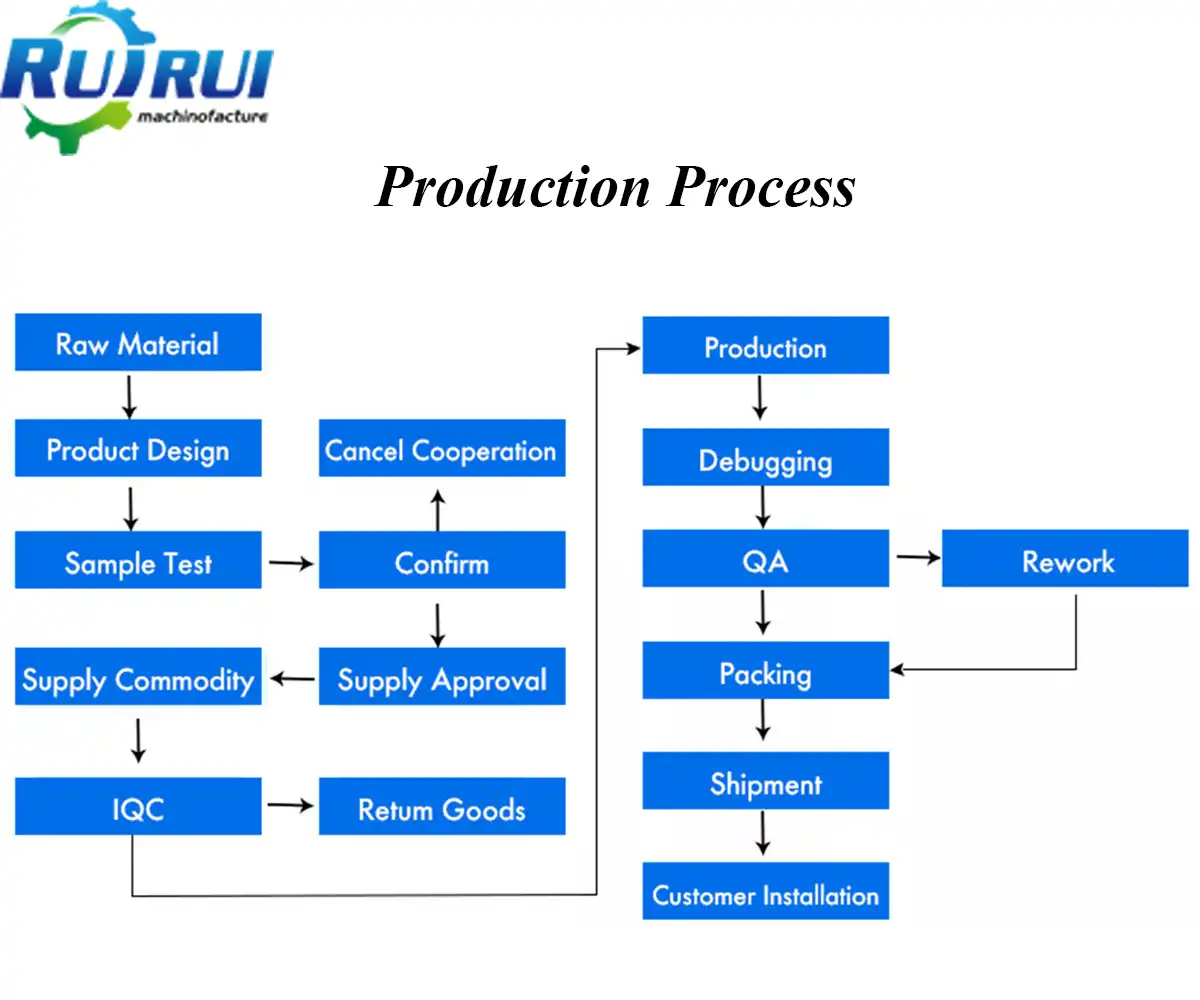

Quality Assurance and Manufacturing Excellence in Heavy Duty Trailer Jack Production

The production of reliable heavy duty trailer jack systems requires stringent quality control measures and advanced manufacturing capabilities. Understanding these processes helps buyers evaluate supplier capabilities and product quality.

-

ISO Certification and Quality Management Systems

RUIRUI's manufacturing facility maintains comprehensive quality management certifications including ISO 9001, ISO 14001, and OHSAS 18001 standards. These certifications ensure consistent product quality, environmental responsibility, and workplace safety throughout the manufacturing process. Each heavy duty trailer jack undergoes rigorous testing including load verification, dimensional inspection, and surface finish evaluation. The trailer jack foot plate components receive particular attention during quality control processes to ensure proper fit and long-term durability.

-

Advanced Manufacturing Capabilities and Process Control

Modern heavy duty trailer jack production utilizes automated manufacturing systems including robotic production lines and computerized quality control systems. RUIRUI's facility features eight production lines with an annual capacity of 130,000 pieces, ensuring consistent availability and competitive delivery times. Advanced processes including CNC machining, laser cutting, and precision welding create heavy duty trailer jack components with exceptional dimensional accuracy and surface finish quality. Secondary operations including polishing, powder coating, and plating provide superior corrosion resistance and aesthetic appeal.

Conclusion

Heavy duty trailer jack systems represent a critical investment for professionals requiring reliable support for extreme loads. The combination of advanced engineering, premium materials, and sophisticated manufacturing processes creates products capable of meeting the most demanding applications. When selecting a heavy duty trailer jack, consider load requirements, operating environment, and long-term reliability factors to ensure optimal performance and value.

Cooperate with Qingdao RUIRUI Machinary Co., LTD.

As a leading China heavy duty trailer jack manufacturer established in 2016, Qingdao RUIRUI Machinary Co., LTD. combines over 15 years of management experience with cutting-edge manufacturing technology to deliver superior heavy duty trailer jack solutions. Our fully automated robot production lines and advanced thermoplastic coating processes ensure consistent quality and competitive pricing. As a trusted China heavy duty trailer jack supplier, we specialize in producing premium trailer jack foot plate assemblies and complete heavy duty trailer jack systems with customization capabilities to meet your specific requirements.

Our comprehensive manufacturing capabilities include CNC machining, laser cutting, progressive stamping, and advanced surface treatment processes including anodizing, powder coating, and electrophoresis. As an experienced China heavy duty trailer jack factory, we maintain ISO certifications and have developed numerous utility model patents. Our global reach extends to over 80 countries, making us your reliable partner for high quality heavy duty trailer jack wholesale opportunities.

Whether you need heavy duty trailer jack for sale in bulk quantities or custom solutions, our experienced R&D team provides OEM support with competitive heavy duty trailer jack price options and delivery times of 8-26 days. Contact us at info@qdkshd.com to discuss your requirements and discover why leading companies choose RUIRUI as their preferred heavy duty trailer jack manufacturer for premium quality and exceptional service.

FAQ

Q: What is the maximum load capacity for heavy duty trailer jacks?

A: Heavy duty trailer jacks typically support 5,000 to 15,000 pounds, with RUIRUI units handling up to 12,000 pounds safely.

Q: How often should heavy duty trailer jacks be maintained?

A: Regular lubrication every 6 months and annual inspections ensure optimal performance and longevity of heavy duty trailer jack systems.

Q: What materials are used in heavy duty trailer jack construction?

A: Premium steel construction with specialized coatings including powder coating, anodizing, and plating for corrosion resistance and durability.

Q: Can heavy duty trailer jacks be customized for specific applications?

A: Yes, RUIRUI offers extensive customization options including load capacity, mounting configurations, and specialized trailer jack foot plate designs.

References

1. "Heavy-Duty Trailer Jack Design and Manufacturing Standards" - American Society of Mechanical Engineers Industrial Standards Committee

2. "Load Distribution Analysis in Trailer Support Systems" - Dr. Michael Thompson, Mechanical Engineering Research Institute

3. "Corrosion Protection Methods for Heavy Equipment Applications" - Materials Science and Engineering Journal Editorial Board

4. "Quality Control Systems in Heavy Machinery Manufacturing" - International Organization for Standardization Technical Committee

Send Inquiry

You may like