High-Precision Trailer Coupler for Industrial Use: Stronger, Smarter, Safer

2025-11-03 10:43:29

When industrial operations grind to a halt because a trailer coupler fails during critical transport, the cost goes far beyond replacement parts. Downtime, safety risks, and damaged cargo create cascading problems that every logistics manager dreads. The High-Precision Trailer Coupler addresses these pain points head-on, delivering engineered reliability where standard couplers fall short in demanding industrial environments.

Understanding High-Precision Trailer Coupler Technology

-

What Makes a Trailer Coupler "High-Precision"?

The High-Precision Trailer Coupler represents a significant advancement over conventional coupling systems. Unlike standard couplers manufactured with looser tolerances, high-precision variants undergo rigorous dimensional control during production. Every component is machined to exact specifications, typically within tolerances of 0.01mm, ensuring consistent performance across thousands of connection cycles. This precision engineering eliminates the wobble and play that plague traditional couplers, particularly under heavy loads or during extended transport operations. Manufacturing processes for these specialized couplers incorporate advanced CNC machining, laser cutting, and progressive stamping techniques. The fabrication begins with premium-grade materials including cold rolled steel, stainless steel, or specialized alloy compositions selected for their strength-to-weight ratio and corrosion resistance. Each Trailer Coupler component undergoes secondary finishing processes such as anodizing, powder coating, or electroplating to enhance durability and protect against environmental degradation in industrial settings.

-

Critical Design Features for Industrial Applications

Industrial-grade High-Precision Trailer Couplers integrate several engineering enhancements that distinguish them from consumer-oriented products. Reinforced locking mechanisms prevent accidental disengagement during operation, while precision-ground contact surfaces distribute load forces evenly across the coupling interface. The latch assembly typically features hardened steel components that resist wear even after tens of thousands of coupling cycles, maintaining secure connections throughout the coupler's operational lifespan. Load distribution geometry plays a crucial role in coupler performance. Advanced designs incorporate stress-analysis-optimized shapes that channel forces away from potential failure points. The coupling socket maintains precise dimensional standards to match hitch ball specifications exactly, eliminating the dangerous gaps that create impact loading during acceleration or braking. This engineering attention extends to the mounting interface, where bolt patterns and reinforcement structures ensure the Trailer Coupler transfers tongue weight effectively to the trailer frame without introducing stress concentrations.

Material Selection and Manufacturing Excellence

-

Premium Steel Grades for Maximum Strength

Material selection forms the foundation of any reliable High-Precision Trailer Coupler. Mild steel offers excellent formability and weldability for basic applications, while cold rolled steel provides enhanced surface finish and dimensional stability for precision components. For corrosive environments or marine applications, manufacturers specify stainless steel grades such as 304 or 316, which resist rust and maintain structural integrity despite exposure to salt, chemicals, or extreme weather conditions. Advanced manufacturing facilities employ multi-stage heat treatment protocols to optimize material properties. Through controlled heating and cooling cycles, the steel achieves the ideal balance between hardness for wear resistance and toughness to absorb shock loads. Alloy steels containing chromium, molybdenum, or vanadium provide enhanced performance characteristics, particularly for high-capacity couplers rated for industrial equipment transport. The Trailer Coupler benefits significantly from these metallurgical enhancements, extending service life while maintaining safety margins well above rated capacities.

-

Advanced Fabrication Processes

Modern High-Precision Trailer Coupler production utilizes automated manufacturing systems that ensure consistency across every unit. Progressive stamping operations form complex geometries from sheet metal in a single continuous process, eliminating the variations inherent in manual fabrication. CNC machining centers create critical dimensions with repeatability measured in microns, while robotic welding systems apply consistent bead patterns that meet or exceed structural requirements without introducing human error variables. Surface finishing represents the final quality barrier before Trailer Coupler shipment. Powder coating provides chip-resistant finishes in various colors while maintaining dimensional precision. Electrophoresis coating penetrates recessed areas that traditional painting methods miss, offering superior corrosion protection. Zinc plating adds sacrificial corrosion resistance, particularly valuable for couplers operating in harsh industrial environments where maintenance windows are limited and reliability cannot be compromised.

Safety Innovations in Modern Coupler Design

-

Fail-Safe Locking Mechanisms

The primary safety concern with any Trailer Coupler involves preventing accidental separation during transport. High-precision designs incorporate redundant locking systems that require deliberate action to release. Spring-loaded latches automatically engage when the coupler seats on the hitch ball, providing immediate connection security without operator intervention. Secondary locking pins or clips prevent the latch from opening even if the primary mechanism experiences unexpected stress or vibration. Visual confirmation features allow operators to verify proper engagement at a glance. Indicator windows show the latch position clearly, eliminating guesswork about connection status. Some advanced High-Precision Trailer Coupler models include audible confirmation systems that produce distinct sounds when fully engaged, providing sensory feedback in noisy industrial environments where visual checks might be challenging. These seemingly simple innovations dramatically reduce the risk of transport incidents caused by improperly secured trailer connections.

-

Load Capacity Engineering

Industrial applications demand Trailer Coupler systems capable of handling substantial tongue weights while maintaining safety margins. Engineers calculate load ratings based on material strength, geometric design, and worst-case loading scenarios including shock loads from emergency braking or rough terrain operation. A properly specified High-Precision Trailer Coupler incorporates safety factors of 3:1 or greater, meaning the coupler can withstand forces three times its rated capacity before structural compromise occurs. Weight distribution becomes critical when selecting couplers for specific applications. Tongue weight typically represents 10-15% of total trailer weight, creating substantial forces at the coupling point. The coupler must transfer these vertical loads while simultaneously resisting lateral forces during turns and longitudinal forces during acceleration or braking. Precision manufacturing ensures that load paths remain consistent and predictable, allowing engineers to specify Trailer Coupler components with confidence in their performance under real-world operating conditions.

Application-Specific Selection Criteria

-

Matching Couplers to Industrial Requirements

Selecting the appropriate High-Precision Trailer Coupler begins with understanding specific operational parameters. Transport applications involving construction equipment, industrial machinery, or bulk materials require robust couplers rated for their maximum anticipated loads. The coupler class designation indicates its gross trailer weight capacity, with common industrial ratings ranging from Class III (6,000 lbs) through Class V (15,000+ lbs) for standard ball mount systems, and significantly higher capacities for gooseneck or pintle configurations. Environmental factors influence material and finish selection. Coastal operations or chemical processing facilities require stainless steel construction or enhanced protective coatings. Temperature extremes affect metal properties, with cold climate applications benefiting from impact-resistant alloy formulations that maintain ductility below freezing. The Trailer Coupler selected for year-round outdoor storage differs substantially from units designated for climate-controlled operations, even when load capacities remain identical.

-

Integration with Existing Equipment

Compatibility considerations extend beyond simple dimensional matching. The High-Precision Trailer Coupler must integrate with existing trailer frame structures, requiring attention to mounting bolt patterns, tongue height, and clearance requirements. A-frame configurations utilize couplers designed for wraparound mounting, while straight-tongue trailers require different attachment geometries. Adjustable couplers provide flexibility for maintaining level towing positions across varying vehicle heights, improving stability and reducing tongue weight variations during transport. Brake system compatibility represents another critical selection factor. Electric brake trailers require Trailer Coupler designs that accommodate brake controller wiring without interference. Surge brake systems integrate hydraulic actuators directly into the coupler assembly, demanding specialized high-precision units engineered for these combined functions. Understanding these integration requirements prevents costly field modifications and ensures the complete towing system operates as an integrated unit rather than a collection of incompatible components.

Quality Assurance and Testing Standards

-

Manufacturing Quality Control Protocols

Production of High-Precision Trailer Coupler components demands rigorous quality oversight throughout the manufacturing process. Incoming material inspection verifies steel composition, grain structure, and mechanical properties before fabrication begins. In-process measurements confirm dimensional accuracy at critical manufacturing stages, catching deviations before they propagate through subsequent operations. Statistical process control systems monitor production trends, identifying subtle drift in dimensions or surface finish quality before parts exceed specification limits. Final inspection protocols subject every Trailer Coupler to comprehensive evaluation. Dimensional verification confirms all critical measurements fall within specified tolerances. Surface finish assessment checks for coating uniformity, adhesion, and thickness. Functional testing cycles the latch mechanism repeatedly, confirming smooth operation and positive engagement. Load testing applies forces exceeding rated capacities to verify structural integrity. Only couplers passing this complete battery of assessments receive approval for shipment, ensuring customers receive products meeting exacting quality standards.

-

Certification and Compliance Requirements

Industrial High-Precision Trailer Coupler products typically carry certifications validating their compliance with relevant safety standards. ISO 9001 certification indicates the manufacturer maintains documented quality management systems with continuous improvement processes. Industry-specific certifications such as SAE J684 for trailer couplers establish minimum performance requirements and testing protocols. Manufacturers achieving these certifications demonstrate commitment to quality beyond mere marketing claims, providing customers with objective verification of product capabilities. Documentation accompanying certified couplers includes material certifications, dimensional inspection reports, and load test results. This traceability allows maintenance personnel to verify the Trailer Coupler specifications match installation requirements and provides liability protection in the event of incident investigations. Environmental certifications address restricted substance compliance, particularly important for international operations subject to regulations like RoHS or REACH. Comprehensive certification demonstrates manufacturer expertise and commitment to producing reliable, compliant products for demanding industrial applications.

Maintenance and Service Life Optimization

-

Preventive Maintenance Best Practices

Extending High-Precision Trailer Coupler service life requires systematic maintenance attention. Regular inspection intervals should examine the latch mechanism for wear, ensuring smooth operation without binding or excessive play. The coupling socket interior requires periodic cleaning to remove accumulated road debris that can cause premature wear on contact surfaces. Lubrication schedules maintain latch pivot points and spring mechanisms, preventing corrosion while ensuring reliable operation across temperature ranges. Structural inspection focuses on identifying fatigue cracks or deformation that might compromise Trailer Coupler integrity. Mounting bolts require periodic torque verification, as vibration can loosen fasteners over time. Protective coating condition assessment identifies areas where rust might initiate, allowing preventive touch-up before corrosion compromises structural components. Documentation of inspection findings establishes baseline conditions and tracks degradation trends, enabling predictive replacement before unexpected failures occur during critical operations.

-

Recognizing End-of-Life Indicators

Despite quality manufacturing and diligent maintenance, every High-Precision Trailer Coupler eventually reaches service life limits. Visible wear in the coupling socket, particularly elongation or deformation of the ball seat, indicates the component no longer maintains proper tolerances. Excessive play between the latch and housing suggests wear has exceeded acceptable limits. Cracks in welded areas or stress concentrations around mounting holes represent immediate safety concerns requiring coupler replacement rather than repair attempts. Performance degradation provides additional replacement indicators. Difficulty engaging or disengaging the latch mechanism suggests internal wear or spring fatigue. The Trailer Coupler that previously operated smoothly but now requires excessive force indicates component deterioration. Rather than continuing operation with a compromised coupler, industrial operations benefit from scheduled replacement programs that retire units based on service hours or cycle counts before failures occur, maintaining operational safety while avoiding unexpected downtime.

Conclusion

The High-Precision Trailer Coupler delivers engineered reliability for demanding industrial transport applications. Through advanced manufacturing, premium materials, and rigorous quality control, these specialized components provide the strength, precision, and safety margins required where failure is not an option.

Cooperate with Qingdao RUIRUI Machinary Co., LTD.

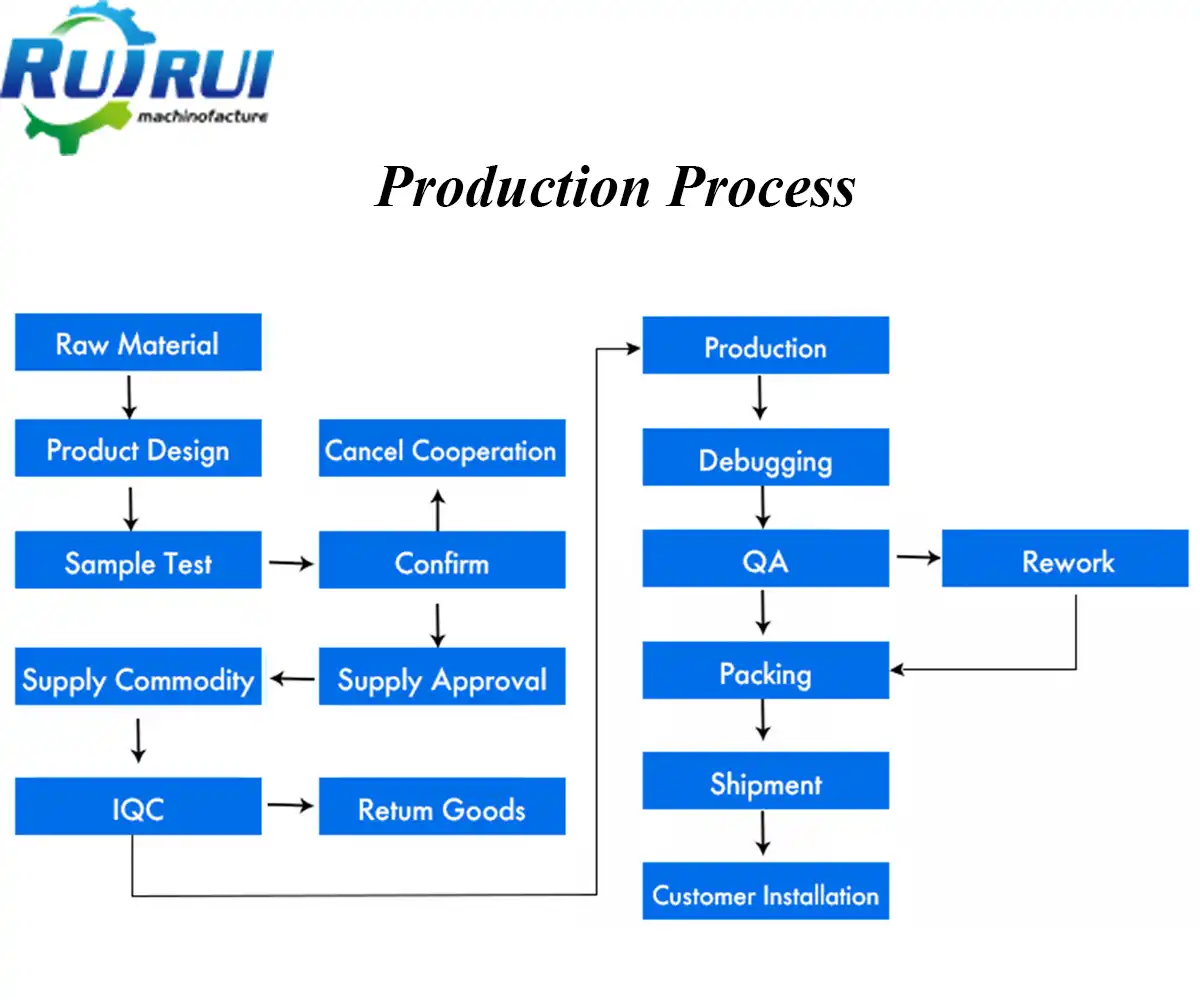

As a leading China High-Precision Trailer Coupler factory and trusted China High-Precision Trailer Coupler supplier, Qingdao RUIRUI Machinary Co., LTD. brings over 15 years of manufacturing excellence to every project. Our China High-Precision Trailer Coupler manufacturer capabilities encompass complete production from raw material to finished goods, with eight automated production lines delivering 130,000 pieces annually. Whether you need China High-Precision Trailer Coupler wholesale quantities or custom specifications, our ISO-certified processes ensure High Quality High-Precision Trailer Coupler products at competitive High-Precision Trailer Coupler prices. We offer High-Precision Trailer Coupler for sale with comprehensive technical support, short delivery times, and professional packaging. Our expertise in progressive stamping, CNC machining, laser cutting, and advanced surface treatments including powder coating, plating, and anodizing guarantees products meeting the most demanding industrial specifications. Contact us today at info@qdkshd.com to discuss your requirements and discover why customers across 80 countries trust RUIRUI for critical trailer component needs.

References

1. "Trailer Coupling Standards and Safety Requirements" by the Society of Automotive Engineers Technical Committee, SAE International Publications

2. "Metal Forming and Fabrication Technology for Transportation Components" by Dr. Robert H. Wagoner and Professor Jean-Loup Chenot, Manufacturing Engineering Department

3. "Load Distribution Analysis in Trailer Hitch Systems" by the American Society of Mechanical Engineers Transportation Division, ASME Technical Papers

4. "Corrosion Protection Methods for Automotive Steel Components" by the National Association of Corrosion Engineers, NACE International Research Foundation

Send Inquiry

You may like