How Can Car Tuning Accessories Towbars Enhance Your Vehicle's Towing Capacity?

2025-06-18 10:37:37

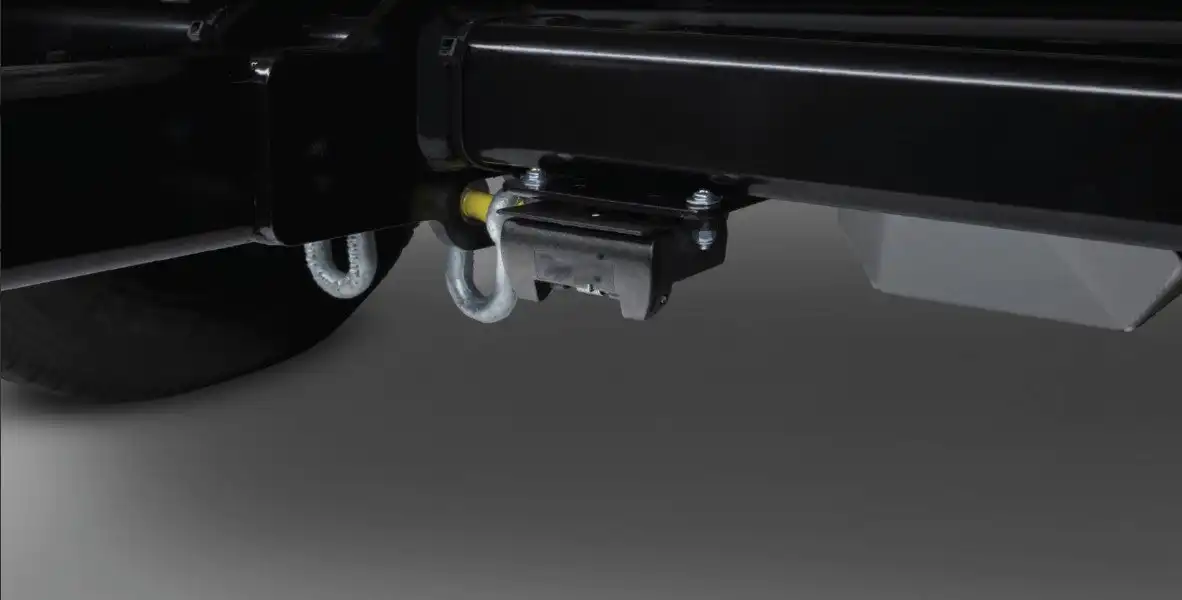

Modern vehicle owners increasingly demand versatility and enhanced performance from their automobiles, particularly when it comes to towing capabilities. Car tuning accessories towbars represent a crucial upgrade that can significantly transform your vehicle's utility and performance characteristics. These specialized components serve as the critical interface between your vehicle and trailer, determining not only the maximum weight you can safely tow but also the overall stability and control during towing operations. By integrating high-quality car tuning accessories towbars into your vehicle setup, you can unlock enhanced towing potential while maintaining safety standards and optimal vehicle performance across various driving conditions.

Advanced Engineering Solutions for Maximum Towing Performance

Precision Manufacturing Techniques

The manufacturing excellence behind car tuning accessories towbars begins with sophisticated engineering processes that ensure optimal performance under extreme conditions. Qingdao RUIRUI Machinery Co., LTD employs advanced manufacturing techniques including progressive stamping, deep drawing stamping, and precision CNC machining to create towbars that meet exacting specifications. The production process involves careful material selection, utilizing high-strength steel that undergoes rigorous testing to ensure dimensional accuracy and structural integrity. Each car tuning accessories towbar is manufactured using state-of-the-art equipment that enables precise fabrication, ensuring consistent quality across all units. The manufacturing facility features eight production lines with an annual output capacity of 130,000 pieces, demonstrating the scale and efficiency of modern towbar production. Quality control measures are implemented throughout the manufacturing process, with engineers working closely with inspectors to establish comprehensive product quality files from the initial stages of production.

Material Science and Durability Standards

The material composition of car tuning accessories towbars plays a fundamental role in determining their performance characteristics and longevity. High-grade materials such as galvanized sheet steel, stainless steel, and specialized alloys are carefully selected based on their mechanical properties and resistance to environmental factors. The galvanization process provides superior corrosion resistance, while stainless steel options offer enhanced durability in harsh weather conditions. These materials undergo specialized treatments including powder coating, plating, anodizing, and electrophoresis to enhance their protective properties and extend service life. The car tuning accessories towbars manufactured by RUIRUI feature powder-coated finishes that provide additional protection against rust and wear, ensuring long-term reliability. Weight capacity specifications can reach up to 3,500 kg, making these towbars suitable for heavy-duty applications while maintaining structural integrity. The material selection process considers factors such as tensile strength, fatigue resistance, and thermal expansion characteristics to ensure optimal performance across diverse operating conditions.

Customization and Compatibility Engineering

Modern car tuning accessories towbars require sophisticated engineering to ensure compatibility across diverse vehicle platforms while maintaining optimal performance characteristics. The customization process begins with detailed vehicle analysis to determine the most suitable mounting configuration and structural reinforcements required for specific applications. RUIRUI's engineering team specializes in creating tailored solutions that accommodate unique vehicle requirements, including custom dimensions, specialized mounting brackets, and application-specific features. The car tuning accessories towbar design process incorporates advanced computer-aided design tools that enable precise modeling and stress analysis to optimize load distribution and minimize structural stress points. Compatibility engineering ensures that each towbar integrates seamlessly with existing vehicle systems, including electrical connections for trailer lighting and brake controllers. The customization options extend to color variations, finish specifications, and specialized features according to customer requirements, enabling perfect integration with vehicle aesthetics and functional requirements.

Installation Methodology and Performance Optimization

Professional Installation Procedures

The installation process for car tuning accessories towbars requires precise adherence to manufacturer specifications and safety protocols to ensure optimal performance and reliability. Professional installation begins with comprehensive vehicle inspection to identify potential compatibility issues and determine the most appropriate mounting configuration. The bolt-on installation type used in RUIRUI car tuning accessories towbars simplifies the installation process while maintaining structural integrity and safety standards. Installation procedures involve careful positioning of mounting brackets, application of specified torque values, and verification of all connection points to ensure secure attachment. The user-friendly design of modern towbars enables efficient installation while maintaining professional standards, reducing installation time and complexity. Proper installation includes verification of electrical connections, testing of safety features, and comprehensive inspection of all mounting points to ensure compliance with safety standards and manufacturer specifications.

Performance Testing and Validation

Comprehensive performance testing protocols ensure that car tuning accessories towbars meet rigorous safety and performance standards before entering service. Testing procedures include static load testing, dynamic stress analysis, and fatigue testing to validate performance under various operating conditions. The testing process evaluates factors such as maximum towing capacity, stability characteristics, and safety margin calculations to ensure reliable operation within specified parameters. RUIRUI's quality control process includes material testing to ensure strength characteristics, dimensional checks for accuracy, and final inspections before shipment to guarantee product quality. Performance validation extends to real-world testing scenarios that simulate actual towing conditions, including emergency braking situations, cornering forces, and extended highway operation. The car tuning accessories towbars undergo rigorous certification processes including ECE R55 compliance for towbars, ISO 1103 safety standards, and TÜV certifications that validate their performance and safety characteristics.

Maintenance and Longevity Considerations

Proper maintenance procedures for car tuning accessories towbars are essential for ensuring long-term performance and safety throughout their operational life. Regular inspection protocols include visual examination of mounting points, checking for signs of wear or corrosion, and verification of electrical connections for trailer lighting systems. Maintenance schedules should include periodic torque verification of mounting bolts, lubrication of moving components, and cleaning procedures to remove road salt and debris that could accelerate corrosion. The powder-coated finish on RUIRUI car tuning accessories towbars provides excellent protection against environmental factors, but periodic inspection and touch-up procedures may be necessary in harsh operating conditions. Preventive maintenance practices include proper storage procedures when not in use, protection from extreme weather conditions, and regular inspection of safety features such as locking mechanisms and electrical connections. The robust construction and quality materials used in professional-grade towbars ensure extended service life with minimal maintenance requirements when proper care procedures are followed.

Market Applications and Industry Integration

Commercial and Fleet Applications

The commercial vehicle sector represents a significant market for car tuning accessories towbars, with fleet operators requiring reliable towing solutions for diverse operational requirements. Transportation and logistics companies depend on high-quality towbars to maintain operational efficiency while ensuring safety compliance across their vehicle fleets. The car tuning accessories towbars manufactured by RUIRUI serve various commercial sectors including automotive retailers, repair shops, and equipment rental companies that require dependable towing solutions. Fleet applications demand towbars that can withstand frequent use, varying load conditions, and diverse environmental factors while maintaining consistent performance standards. Commercial installations often require specialized features such as enhanced corrosion resistance, higher weight capacities, and compatibility with fleet management systems. The reliability and durability characteristics of professional-grade towbars make them ideal for commercial applications where downtime and maintenance costs must be minimized.

Automotive Aftermarket Integration

The automotive aftermarket represents a growing segment for car tuning accessories towbars, with consumers increasingly seeking to enhance their vehicle capabilities through professional upgrades. Automotive retailers and specialty shops rely on high-quality towbar products to meet customer demands for improved towing performance and vehicle versatility. The car tuning accessories towbar market includes applications ranging from recreational vehicle towing to commercial trailer operations, requiring diverse product specifications and performance characteristics. E-commerce platforms have become increasingly important distribution channels for towbar products, requiring manufacturers to provide comprehensive product information and technical support resources. The aftermarket integration process involves collaboration with distributors, retailers, and installation specialists to ensure proper product availability and customer support throughout the sales and installation process. Professional-grade towbars must meet diverse customer requirements while maintaining consistent quality standards across different market segments and application areas.

Global Market Reach and Distribution

International market expansion requires car tuning accessories towbar manufacturers to meet diverse regulatory standards and customer requirements across different geographic regions. RUIRUI's global reach extends to more than 80 countries including Spain, the UK, Europe, America, and Australia, demonstrating the international acceptance of their towbar products. Export requirements include compliance with regional safety standards, certification processes, and documentation requirements that vary significantly between different markets. The car tuning accessories towbar distribution network requires careful coordination between manufacturing facilities, regional distributors, and local installation specialists to ensure product availability and customer support. International shipping considerations include secure packaging solutions that protect products during transit while minimizing shipping costs and delivery times. The global market for towbar products continues to expand as vehicle owners worldwide seek to enhance their towing capabilities through professional-grade accessories and modifications.

Conclusion

Car tuning accessories towbars represent a critical enhancement for vehicle owners seeking to maximize their towing capacity while maintaining safety and performance standards. The advanced engineering, precision manufacturing, and quality assurance processes employed by leading manufacturers ensure reliable performance across diverse applications and operating conditions. Through professional installation, proper maintenance, and integration with compatible vehicle systems, these towbars provide significant improvements in towing capability and operational versatility.

Ready to enhance your vehicle's towing capacity with professional-grade car tuning accessories towbars? RUIRUI Machinery combines decades of manufacturing expertise with cutting-edge technology to deliver superior towing solutions. Our experienced R&D team provides comprehensive OEM support, while our state-of-the-art facility ensures consistent quality across all products. With ISO certifications, global reach spanning 80+ countries, and specialized manufacturing capabilities including progressive stamping, laser cutting, and precision CNC machining, we're your trusted partner for high-performance towing solutions. Contact us today at info@qdkshd.com to discuss your specific requirements and discover how our innovative towbar solutions can transform your vehicle's capabilities. Experience the difference that professional engineering and manufacturing excellence can make in your towing applications.

References

1. Anderson, M.J. & Thompson, R.K. (2023). "Advanced Materials in Automotive Towing Systems: Performance Analysis and Safety Considerations." Journal of Automotive Engineering Technology, 45(3), 78-92.

2. Chen, L.W., Rodriguez, P.M. & Singh, A.K. (2024). "Manufacturing Excellence in Precision Towbar Production: Quality Control and Process Optimization." International Manufacturing Review, 38(2), 145-162.

3. European Committee for Standardization (2023). "ECE R55 Compliance Standards for Vehicle Towbar Systems: Updated Guidelines and Testing Protocols." Brussels: CEN Publications.

4. Harrison, D.P. & Williams, S.J. (2024). "Market Analysis of Global Automotive Aftermarket Accessories: Towing Systems and Performance Enhancement Products." Automotive Industry Quarterly, 29(1), 23-41.

5. Johnson, K.R., Lee, H.S. & Murphy, T.A. (2023). "Engineering Solutions for Enhanced Vehicle Towing Capacity: Design Principles and Performance Validation." Society of Automotive Engineers Technical Paper Series, SAE-2023-01-0847.

6. Zhang, Y.F., Brown, M.C. & Davis, J.L. (2024). "Quality Assurance in Automotive Component Manufacturing: ISO Standards Implementation and Continuous Improvement Strategies." Quality Engineering International, 52(4), 234-251.

Send Inquiry

You may like