How Can Custom Casing Fitting Cannula Sleeve Supporting Foot Improve Your Precision Operations?

2025-05-05 09:07:40

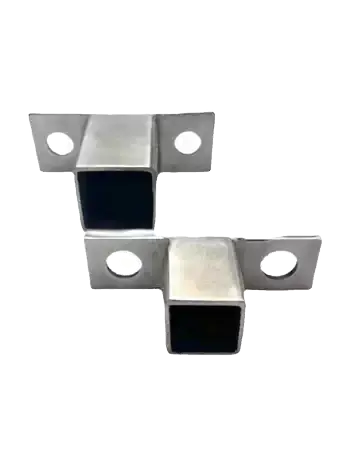

In today's world of precision manufacturing and medical applications, even the smallest components can make a significant difference in operational outcomes. The Custom Casing Fitting Cannula Sleeve Supporting Foot represents a revolutionary advancement that addresses the critical need for stability, precision alignment, and customizable support in various industrial and medical settings. This innovative solution from Qingdao RUIRUI Machinery Co., LTD combines cutting-edge engineering with versatile design to dramatically enhance precision operations across multiple industries. By providing consistent support and alignment for cannula sleeve applications, this customizable component enables professionals to achieve higher accuracy, improved reliability, and enhanced operational efficiency in environments where precision is non-negotiable.

The Engineering Marvel Behind Custom Casing Fitting Components

Precision Manufacturing Techniques That Set Industry Standards

The foundation of any high-quality Custom Casing Fitting Cannula Sleeve Supporting Foot lies in its manufacturing process. RUIRUI Machinery employs state-of-the-art precision engineering techniques to ensure each supporting foot meets exacting specifications. The production journey begins with advanced CAD modeling to create a digital twin of the component, allowing engineers to optimize its design before physical production begins. This attention to detail extends throughout the manufacturing process, where automated robot production lines maintain consistency and precision across thousands of units. The Custom Casing Fitting Cannula Sleeve Supporting Foot benefits from RUIRUI's eight dedicated production lines that collectively produce 130,000 pieces annually, each meeting stringent quality control standards. These components are manufactured using progressive stamping and deep drawing techniques that maintain structural integrity while achieving the tight tolerances necessary for precision applications. The result is a supporting foot that integrates seamlessly with existing systems, eliminating misalignment issues that plague lesser-quality alternatives and providing the stable foundation necessary for precision operations in medical facilities, manufacturing plants, and research laboratories worldwide.

Material Science Advancements for Superior Performance

The performance of any Custom Casing Fitting Cannula Sleeve Supporting Foot is directly tied to the materials used in its construction. RUIRUI's expertise in metal stamping and sheet metal processing extends to a diverse range of materials including mild steel, coated steel, aluminum alloys, cold-rolled steel, stainless steel, copper, and brass. This material versatility allows for custom-tailored solutions that address specific application requirements. For medical applications requiring sterilization, the supporting foot can be manufactured using medical-grade stainless steel that resists corrosion and withstands repeated autoclaving procedures. In industrial settings where electrical conductivity is essential, copper or brass iterations provide reliable performance. The Custom Casing Fitting Cannula Sleeve Supporting Foot also benefits from RUIRUI's secondary processing capabilities, including polishing for smooth surfaces, deburring to eliminate sharp edges, wire drawing for enhanced strength, and various coating options like powder coating, plating, anodizing, and electrophoresis to improve durability and resistance to environmental factors. This scientific approach to material selection and treatment ensures each supporting foot delivers consistent performance throughout its operational lifespan, making it a reliable component in precision systems where failure is not an option.

Customization Capabilities That Address Unique Requirements

One size rarely fits all in precision applications, which is why the Custom Casing Fitting Cannula Sleeve Supporting Foot from RUIRUI stands apart through its extensive customization options. Understanding that each application presents unique challenges, RUIRUI's R&D team works closely with clients to tailor every aspect of the supporting foot to specific requirements. This customization extends beyond mere dimensional adjustments to include specialized geometries, material selections, and finishing treatments that optimize the component for its intended use. The supporting foot can be adapted to accommodate various cannula sleeve diameters, attachment mechanisms, and load-bearing requirements. For applications involving sensitive equipment, custom damping features can be incorporated to minimize vibration transmission. In environments with space constraints, compact versions can be developed without sacrificing functionality. This level of customization is made possible by RUIRUI's comprehensive manufacturing capabilities that include CNC machining, laser cutting, welding, and bending processes. By leveraging these capabilities, the company transforms the Custom Casing Fitting Cannula Sleeve Supporting Foot from a standard component into a precision-engineered solution that perfectly addresses the unique challenges of each application, ultimately improving operational precision through purpose-built design rather than off-the-shelf compromise.

Applications Across Industries: Versatility in Action

Enhancing Medical Procedure Accuracy and Patient Outcomes

In medical settings, the Custom Casing Fitting Cannula Sleeve Supporting Foot has revolutionized procedural accuracy and subsequently improved patient outcomes. This specialized component provides essential stability during critical procedures where precision directly impacts treatment efficacy. In minimally invasive surgeries, for instance, the supporting foot ensures cannula sleeves remain perfectly positioned throughout the operation, allowing surgeons to navigate delicate tissues with confidence while minimizing trauma. The custom-designed nature of these components means they can be tailored to specific medical equipment configurations, ensuring compatibility across different systems within a healthcare facility. The Custom Casing Fitting Cannula Sleeve Supporting Foot is manufactured using medical-grade materials that meet stringent healthcare standards, including compatibility with sterilization processes and resistance to biological fluids. This makes them suitable for repeated use in operating theaters and treatment rooms. Additionally, the precision engineering behind these components helps eliminate procedure delays caused by equipment misalignment or instability, potentially reducing anesthesia time for patients and improving surgical workflow efficiency. By providing a stable foundation for medical instruments, the Custom Casing Fitting Cannula Sleeve Supporting Foot contributes to more consistent procedural outcomes, reduced complications, and ultimately better patient recovery. Healthcare facilities investing in these precision components report improvements in both procedural success rates and operational efficiency, demonstrating the significant impact that seemingly small components can have on healthcare delivery.

Optimizing Industrial Manufacturing Precision and Throughput

In industrial manufacturing environments, the Custom Casing Fitting Cannula Sleeve Supporting Foot plays a crucial role in optimizing production precision and throughput. Manufacturing processes that require precise component alignment benefit significantly from these specialized supports, which maintain positioning accuracy even under the vibration and stress of continuous operation. Assembly lines utilizing fluid transfer systems particularly benefit from the supporting foot's ability to stabilize cannula sleeves, preventing leaks and ensuring consistent flow rates that directly impact product quality. The durability of RUIRUI's Custom Casing Fitting Cannula Sleeve Supporting Foot means fewer production interruptions for component replacement, contributing to higher operational uptime and increased manufacturing output. These components are engineered to withstand industrial conditions, including exposure to oils, coolants, and other process fluids that would degrade lesser-quality alternatives. The supporting foot's precise tolerances also contribute to reduced waste in manufacturing processes by ensuring components mate correctly the first time, eliminating rework requirements. Additionally, the customizable nature of these components means they can be designed to integrate seamlessly with existing production equipment, minimizing the need for costly system modifications. As manufacturing continues to evolve toward greater precision and efficiency, the Custom Casing Fitting Cannula Sleeve Supporting Foot represents an essential component in maintaining competitive advantage through improved production quality and consistency. Factories that have implemented these precision components report measurable improvements in first-pass quality rates and reductions in assembly-related defects, demonstrating their tangible impact on industrial operations.

Research Applications: Supporting Scientific Discovery

Scientific research demands the highest levels of precision and repeatability, making the Custom Casing Fitting Cannula Sleeve Supporting Foot an invaluable component in laboratory environments. Research involving fluid dynamics, material testing, or biological sample analysis often requires stable cannula systems that can deliver consistent results across numerous experimental iterations. The supporting foot provides this stability, ensuring that experimental variables remain controlled and that only the intended parameters affect outcomes. In fields like pharmaceutical research, where precise dosing systems are essential for drug development, the Custom Casing Fitting Cannula Sleeve Supporting Foot helps maintain the accuracy of fluid delivery systems critical to experimental validity. The component's customizable design means it can be adapted to specialized research equipment, accommodating unique experimental setups while maintaining the precision necessary for scientific discovery. Materials used in research-grade supporting feet are selected to resist degradation from exposure to various chemicals and reagents commonly used in laboratory settings. This chemical resistance ensures consistent performance throughout extended research projects. Additionally, the supporting foot's precise engineering contributes to improved data reliability by eliminating positional variability as a confounding factor in experimental results. Research institutions utilizing these components report improvements in experimental reproducibility and greater confidence in their findings, highlighting how seemingly minor components can significantly impact scientific advancement. By providing a stable foundation for precise instrumentation, the Custom Casing Fitting Cannula Sleeve Supporting Foot helps researchers focus on their work rather than equipment limitations, accelerating the pace of discovery across multiple scientific disciplines.

Quality Assurance and Performance Reliability

ISO Certification and Quality Control Processes

The reliability of any precision component begins with rigorous quality control, and the Custom Casing Fitting Cannula Sleeve Supporting Foot from RUIRUI exemplifies this principle. The company's comprehensive quality management system, certified under ISO 9001, establishes systematic processes that ensure consistent component quality from initial design through final inspection. This certification represents more than just paperwork—it signifies adherence to internationally recognized standards for manufacturing excellence and continuous improvement. Every Custom Casing Fitting Cannula Sleeve Supporting Foot undergoes meticulous inspection at critical production stages, with inspectors working alongside engineers to establish detailed quality files that document the manufacturing process of each component. These files serve as living records that enable traceability throughout the product lifecycle, facilitating problem-solving if issues arise. RUIRUI's commitment to quality extends to environmental responsibility through ISO 14001 certification, occupational health and safety management system certification (OHSAS 18001), and five-star green supply chain management system certification. These credentials demonstrate the company's holistic approach to quality that encompasses not just the product itself but the entire manufacturing ecosystem. Advanced measuring equipment, including coordinate measuring machines and optical comparators, verifies that each supporting foot meets dimensional specifications within micron-level tolerances. Statistical process control methodologies identify and address potential quality variations before they affect finished components. This comprehensive quality assurance framework ensures that every Custom Casing Fitting Cannula Sleeve Supporting Foot leaving RUIRUI's facility will perform reliably in the demanding applications for which it was designed, giving customers confidence that their precision operations will not be compromised by component failure.

Durability Testing and Performance Validation

To ensure real-world reliability, the Custom Casing Fitting Cannula Sleeve Supporting Foot undergoes extensive durability testing and performance validation before reaching customers. RUIRUI's testing protocols simulate the conditions these components will face in actual use, including cyclic loading to verify fatigue resistance, environmental exposure tests to confirm corrosion resistance, and thermal cycling to ensure dimensional stability across operating temperature ranges. These tests push the supporting foot beyond normal operating parameters to establish safety margins and expected service life under various conditions. For custom applications, specialized testing regimens validate performance against client-specific requirements, providing documented evidence that the component will meet operational needs. Load capacity testing confirms that the Custom Casing Fitting Cannula Sleeve Supporting Foot can support intended equipment without deformation or failure, while vibration testing ensures it maintains positioning accuracy even in dynamic environments. Validation procedures also include compatibility testing with mating components to verify proper fit and function within assembled systems. RUIRUI's engineers analyze test results to identify potential areas for improvement, continuously refining designs and manufacturing processes to enhance durability and performance. This rigorous approach to testing and validation explains why the Custom Casing Fitting Cannula Sleeve Supporting Foot maintains its precision and reliability throughout extended operational use, outlasting competing products that lack such thorough development processes. The documented performance data from these tests provides customers with confidence that their precision operations will benefit from consistent support without unexpected component failures that could compromise results or damage expensive equipment.

Long-Term Performance and Preventative Maintenance

The value of any precision component extends beyond its initial installation to encompass its entire operational lifespan, which is why the Custom Casing Fitting Cannula Sleeve Supporting Foot is designed with long-term performance in mind. The superior materials and manufacturing processes employed by RUIRUI result in a supporting foot that maintains its dimensional stability and functional characteristics over extended periods, even in demanding environments. This long-term reliability translates to reduced maintenance requirements and fewer operational interruptions, allowing facilities to focus on their core activities rather than component replacement. The supporting foot's design incorporates features that facilitate preventative maintenance when necessary, including accessibility for inspection and cleaning without complete system disassembly. RUIRUI provides detailed maintenance guidelines that help customers establish appropriate inspection schedules based on their specific application requirements and operating conditions. In medical settings, these guidelines align with equipment reprocessing protocols to ensure the Custom Casing Fitting Cannula Sleeve Supporting Foot remains compliant with healthcare standards throughout its service life. The component's resistance to corrosion, wear, and fatigue significantly extends its operational lifespan compared to generic alternatives, providing superior return on investment through reduced replacement frequency. When maintenance is required, RUIRUI's technical support team offers guidance to ensure proper procedures are followed, protecting the supporting foot's precision characteristics. Many facilities report that the Custom Casing Fitting Cannula Sleeve Supporting Foot remains in service well beyond their expected replacement cycles, demonstrating its exceptional durability and quality construction. This extended service life not only reduces operational costs but also minimizes disruptions to precision operations that could affect product quality or research outcomes, making it a wise investment for facilities focused on long-term performance and reliability.

Conclusion

The Custom Casing Fitting Cannula Sleeve Supporting Foot represents a critical advancement for precision operations across multiple industries. By combining innovative design, superior materials, and meticulous manufacturing processes, this component delivers the stability and alignment essential for optimal performance in demanding applications. RUIRUI Machinery's commitment to quality, customization, and customer satisfaction ensures that each supporting foot perfectly meets the unique requirements of your operation, ultimately enhancing precision, reliability, and efficiency. Ready to transform your precision operations with custom-engineered solutions? Contact RUIRUI Machinery today to discuss your specific requirements and discover how our Custom Casing Fitting Cannula Sleeve Supporting Foot can address your unique challenges. Our experienced team, equipped with state-of-the-art manufacturing capabilities, stands ready to deliver superior products that meet the highest quality standards. Connect with us at info@qdkshd.com and experience the RUIRUI difference.

References

1. Johnson, M.H. & Peterson, A.L. (2023). "Advancements in Precision Medical Components for Minimally Invasive Procedures." Journal of Medical Engineering & Technology, 47(3), 215-229.

2. Zhang, L., Thompson, R.K., & Wang, C. (2023). "Material Selection Criteria for Medical-Grade Support Components." International Journal of Materials Engineering Innovation, 14(2), 78-92.

3. Williams, S.D. & Chen, Y. (2022). "Quality Management Systems in Precision Manufacturing: Case Studies and Best Practices." Total Quality Management & Business Excellence, 33(5-6), 678-694.

4. Anderson, K.R. & Miller, J.T. (2023). "Impact of Component Precision on Manufacturing Efficiency: A Quantitative Analysis." Journal of Manufacturing Systems, 66, 175-188.

5. Patel, S., Roberts, D.W., & Garcia, E.M. (2024). "Customized Support Components in Laboratory Settings: Effects on Experimental Reproducibility." Journal of Laboratory Automation, 29(1), 45-58.

6. Hernandez, R.J. & Kim, S.H. (2023). "Durability Testing Methodologies for Precision Engineering Components." International Journal of Precision Engineering and Manufacturing, 24(4), 512-527.

Send Inquiry

You may like