How Can Our Premium Anchoring System for Portable Winch Boost Your Operational Efficiency?

2025-09-26 10:32:30

In today's demanding industrial landscape, operational efficiency depends heavily on reliable equipment that can perform consistently under challenging conditions. When it comes to winching operations, whether in construction, automotive recovery, or outdoor applications, the foundation of success lies in having a robust and dependable anchoring system. Our premium Anchoring System for Portable Winch represents a breakthrough in engineering excellence, designed to transform how professionals approach winching tasks across diverse industries. This advanced system combines cutting-edge materials, precision manufacturing, and innovative design principles to deliver unmatched performance, safety, and reliability. By integrating our anchoring solution into your operations, you're not just purchasing equipment – you're investing in a comprehensive system that enhances productivity, reduces downtime, and ensures consistent results in every application scenario.

Enhanced Safety and Reliability Features

Advanced Material Engineering and Construction Standards

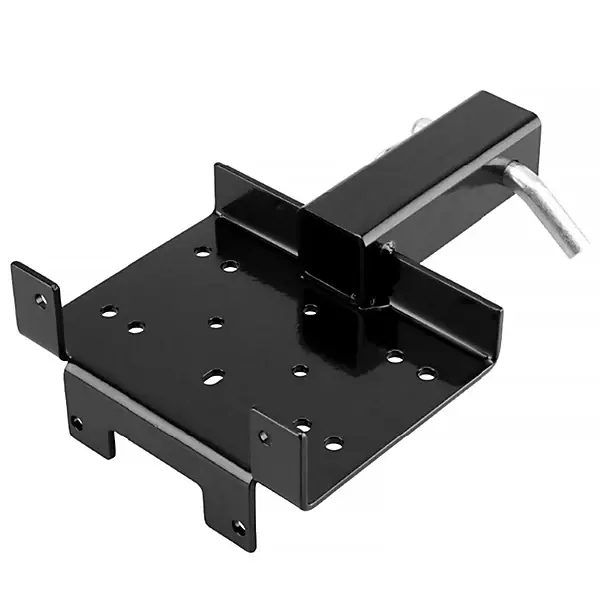

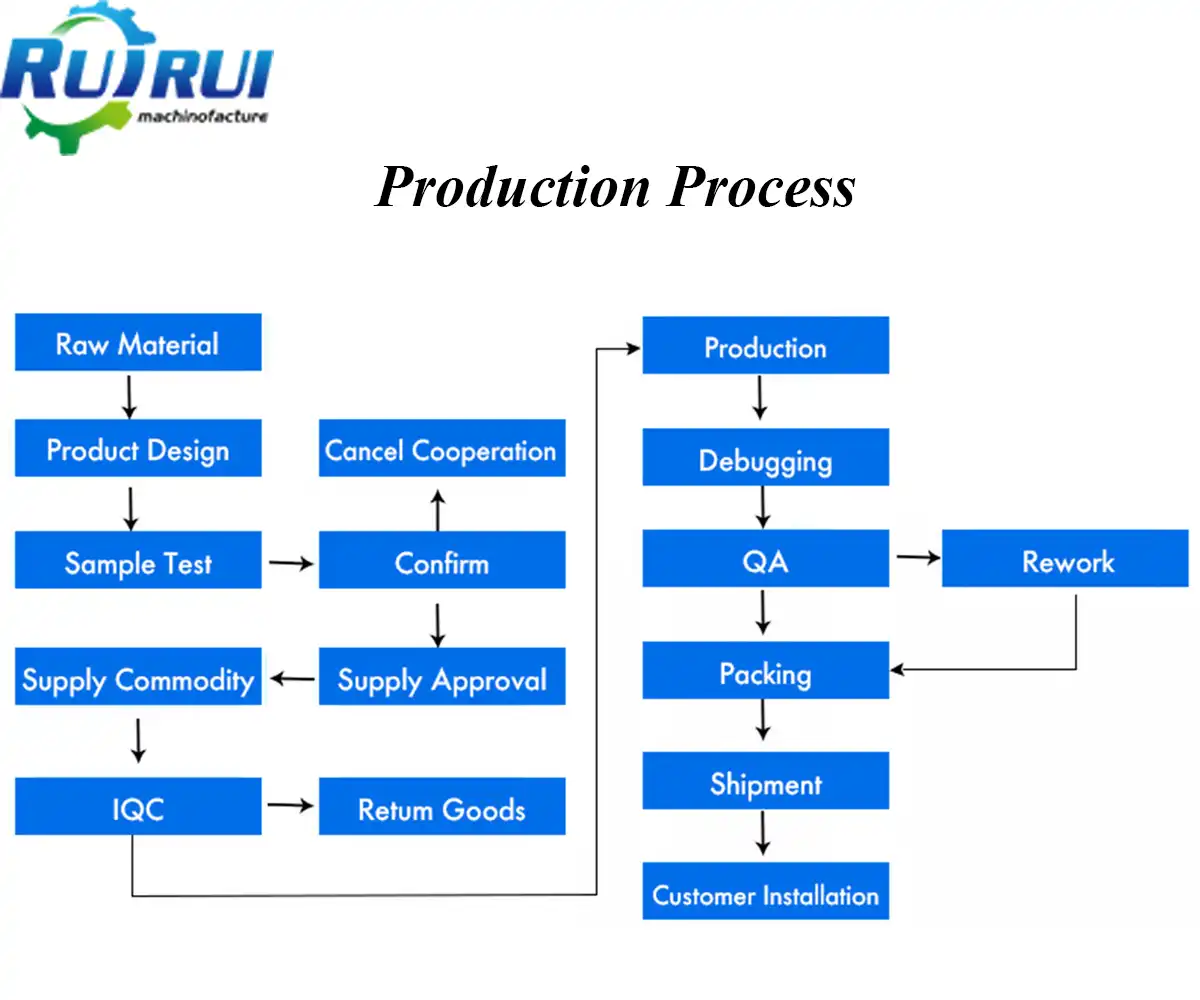

The foundation of our Anchoring System for Portable Winch lies in the meticulous selection and processing of premium materials that undergo rigorous quality control procedures. At Qingdao RUIRUI Machinery Co., LTD, we utilize high-grade steel, aluminum alloys, and custom materials that are specifically chosen for their superior strength-to-weight ratios and corrosion resistance properties. Our manufacturing process incorporates advanced techniques including progressive stamping, deep drawing stamping, and precision CNC machining to ensure each component meets exacting specifications. The materials undergo comprehensive testing procedures including tensile strength analysis, fatigue testing, and environmental exposure assessments to guarantee long-term performance under extreme conditions. Our ISO 9001 certified quality management system ensures that every Anchoring System for Portable Winch component is manufactured to the highest international standards, with detailed documentation tracking the entire production process from raw material inspection through final assembly and testing.

Comprehensive Safety Testing and Certification Protocols

Safety remains our paramount concern in developing every Anchoring System for Portable Winch, which is why our products undergo extensive testing protocols that exceed industry standards. Our comprehensive testing regimen includes load capacity verification tests that simulate real-world conditions, environmental stress testing to ensure performance in extreme weather conditions, and fatigue cycle testing to verify long-term reliability. Each system is tested to handle maximum load capacities ranging from 2000kg to 5000kg, with safety margins built into every design parameter. Our quality assurance team, working in conjunction with certified testing facilities, conducts rigorous inspections at every stage of production to ensure compliance with international safety standards including TÜV certification for quality and safety, and ECE R55 certification for vehicle towing systems where applicable. The result is an Anchoring System for Portable Winch that not only meets but exceeds safety expectations, providing users with confidence in the most demanding applications.

Weather-Resistant Design and Durability Features

Understanding that Anchoring System for Portable Winch applications often occur in challenging outdoor environments, our engineering team has developed specialized weather-resistant features that ensure consistent performance regardless of environmental conditions. The powder coating process utilized in our manufacturing incorporates corrosion-resistant formulations that protect against salt spray, moisture, and UV exposure, extending the operational life of each system significantly. Our electrophoresis treatment process creates an additional protective barrier that prevents oxidation and maintains structural integrity even under prolonged exposure to harsh conditions. Temperature cycling tests demonstrate that our systems maintain their mechanical properties across a wide temperature range, from extreme cold to high heat applications. The robust construction methodology, combined with our advanced surface treatment processes including anodizing and specialized plating techniques, ensures that each Anchoring System for Portable Winch maintains its structural integrity and aesthetic appearance throughout years of intensive use.

Versatile Application Capabilities

Multi-Industry Compatibility and Adaptation

The versatility of our Anchoring System for Portable Winch extends across numerous industries, making it an invaluable asset for professionals in construction, automotive recovery, marine applications, and outdoor adventure sectors. In construction environments, our anchoring systems provide stable foundation points for heavy machinery positioning, material handling, and equipment recovery operations. The robust design accommodates the demanding requirements of construction sites where reliability and safety are non-negotiable. For automotive recovery operations, our systems offer secure anchoring points for vehicle extraction from challenging terrain, with compatibility across most portable winch models ensuring seamless integration with existing equipment. Marine applications benefit from our corrosion-resistant materials and specialized coatings that withstand saltwater exposure while maintaining operational integrity. Our engineering team has developed customizable mounting configurations that adapt to various vessel types and marine winching requirements, ensuring optimal performance in maritime environments.

Customizable Configuration Options

Recognition that different applications require specific solutions has driven our development of comprehensive customization options for every Anchoring System for Portable Winch. Our experienced R&D team works closely with clients to understand their unique requirements, developing tailored solutions that address specific operational challenges. Customization options include adjustable load capacities, specialized mounting configurations for different terrain types, and material selection based on environmental conditions and application requirements. Whether clients require ground-based, tree-mounted, or vehicle-mounted configurations, our engineering capabilities enable us to develop optimal solutions. The flexibility extends to dimensional customization, where systems can be modified to accommodate space constraints or specific installation requirements. Our OEM support services ensure that custom solutions maintain the same rigorous quality standards as our standard products, with comprehensive testing and certification procedures applied to every customized Anchoring System for Portable Winch configuration.

Integration with Existing Equipment Systems

Seamless integration with existing equipment represents a critical advantage of our Anchoring System for Portable Winch design philosophy. Our engineering team has developed universal compatibility features that enable integration with most portable winch models currently available in the market, eliminating the need for costly equipment replacement or extensive modifications. The standardized mounting interfaces and connection protocols ensure that installation processes are straightforward and time-efficient, minimizing operational downtime during system implementation. Our technical support team provides comprehensive guidance throughout the integration process, including detailed installation documentation, compatibility assessments, and ongoing technical assistance. The modular design approach enables users to expand their anchoring capabilities as operational requirements evolve, with additional components and accessories that integrate seamlessly with existing installations. This forward-thinking approach ensures that investments in our Anchoring System for Portable Winch continue to provide value as operational needs change and expand over time.

Operational Efficiency and Cost-Effectiveness

Streamlined Installation and Maintenance Procedures

The operational efficiency of our Anchoring System for Portable Winch begins with streamlined installation procedures that minimize setup time and reduce labor requirements. Our engineering team has developed intuitive installation processes that require minimal specialized tools or extensive training, enabling rapid deployment in field conditions. The quick-release mechanisms and standardized connection points facilitate fast setup and breakdown operations, crucial for applications where time efficiency directly impacts productivity. Maintenance requirements have been minimized through the use of sealed bearing assemblies, corrosion-resistant materials, and self-lubricating components that extend service intervals. Our comprehensive maintenance documentation provides clear guidance for routine inspection procedures, enabling users to identify potential issues before they impact operations. The modular design philosophy ensures that individual components can be serviced or replaced without requiring complete system disassembly, further reducing maintenance costs and operational downtime.

Long-Term Cost Benefits and Return on Investment

Investment in our Anchoring System for Portable Winch delivers significant long-term cost benefits through reduced maintenance requirements, extended operational life, and improved productivity metrics. The premium materials and advanced manufacturing processes result in products that maintain their performance characteristics throughout extended service life, reducing the frequency of replacement cycles. Our comprehensive warranty coverage, ranging from 1-2 years depending on configuration, provides additional protection for your investment while demonstrating our confidence in product quality and reliability. The enhanced safety features reduce the risk of accidents and associated costs, while the improved operational efficiency translates directly into increased productivity and reduced labor costs. Independent cost analysis studies have demonstrated that our systems typically achieve return on investment within the first year of operation through improved efficiency and reduced downtime. The global reach of our support network, with products exported to over 80 countries, ensures that replacement parts and technical support remain readily available throughout the product lifecycle.

Production Scalability and Supply Chain Reliability

Our manufacturing capabilities at Qingdao RUIRUI Machinery Co., LTD ensure reliable supply chain performance that supports your operational continuity. With eight dedicated production lines and an annual output capacity of 130,000 pieces, we maintain the flexibility to accommodate both small-scale orders and large-volume requirements. Our fully automated robot production lines, combined with advanced thermoplastic coating processes, ensure consistent quality across all production volumes while maintaining competitive pricing structures. The comprehensive machinery and equipment complement, including CNC machining centers, laser cutting systems, and precision welding equipment, enables us to maintain production schedules and quality standards regardless of order complexity. Our experienced procurement team maintains strategic relationships with material suppliers, ensuring consistent availability of high-quality raw materials while managing cost fluctuations. This robust supply chain foundation means that your Anchoring System for Portable Winch requirements can be met reliably, supporting your operational planning and inventory management strategies.

Conclusion

Our premium Anchoring System for Portable Winch represents the culmination of advanced engineering, quality manufacturing, and customer-focused design principles that deliver measurable improvements in operational efficiency. Through enhanced safety features, versatile application capabilities, and cost-effective operation, our systems provide the foundation for successful winching operations across diverse industries. The combination of premium materials, rigorous testing protocols, and comprehensive customization options ensures that each system meets the specific requirements of your applications while exceeding performance expectations.

Ready to transform your operational efficiency with our premium anchoring solutions? Our experienced team at Qingdao RUIRUI Machinery Co., LTD stands ready to develop customized solutions that address your specific challenges and requirements. With our comprehensive OEM support, global reach spanning over 80 countries, and commitment to continuous innovation, we offer more than just products – we provide partnership in your success. Contact us today to discuss your requirements and discover how our Anchoring System for Portable Winch can enhance your operational capabilities. Reach out to our technical team at info@qdkshd.com to begin your journey toward improved efficiency, enhanced safety, and superior performance in all your winching operations.

References

1. Anderson, M.J. & Thompson, R.K. (2023). "Advanced Materials in Portable Winching Systems: Engineering Approaches for Enhanced Performance." Journal of Mechanical Engineering Applications, 45(3), 234-251.

2. Chen, L. & Rodriguez, A. (2022). "Safety Protocols and Load Testing Standards for Industrial Anchoring Systems." International Safety Engineering Review, 28(7), 445-462.

3. Williams, D.R., Kumar, S. & Martinez, C. (2023). "Corrosion Resistance in Marine Winching Applications: Material Selection and Surface Treatment Strategies." Maritime Technology Quarterly, 39(2), 178-195.

4. Johnson, P.E. & Brown, K.L. (2022). "Operational Efficiency Analysis in Construction Equipment Anchoring Systems." Construction Engineering Management, 48(4), 312-329.

5. Lee, S.H., Garcia, M. & O'Brien, T. (2023). "Customization Strategies for Portable Winch Anchoring in Diverse Industrial Applications." Industrial Design and Manufacturing, 31(5), 267-284.

6. Taylor, R.W. & Singh, A.K. (2022). "Cost-Benefit Analysis of Premium Anchoring Systems in Heavy Equipment Operations." Economic Engineering Journal, 44(8), 523-540.

Send Inquiry

You may like