How can RUIRUI's extensive experience and R&D in metal fabrication elevate the performance of your required Electrogalvanized U-bolts?

2025-08-19 16:26:00

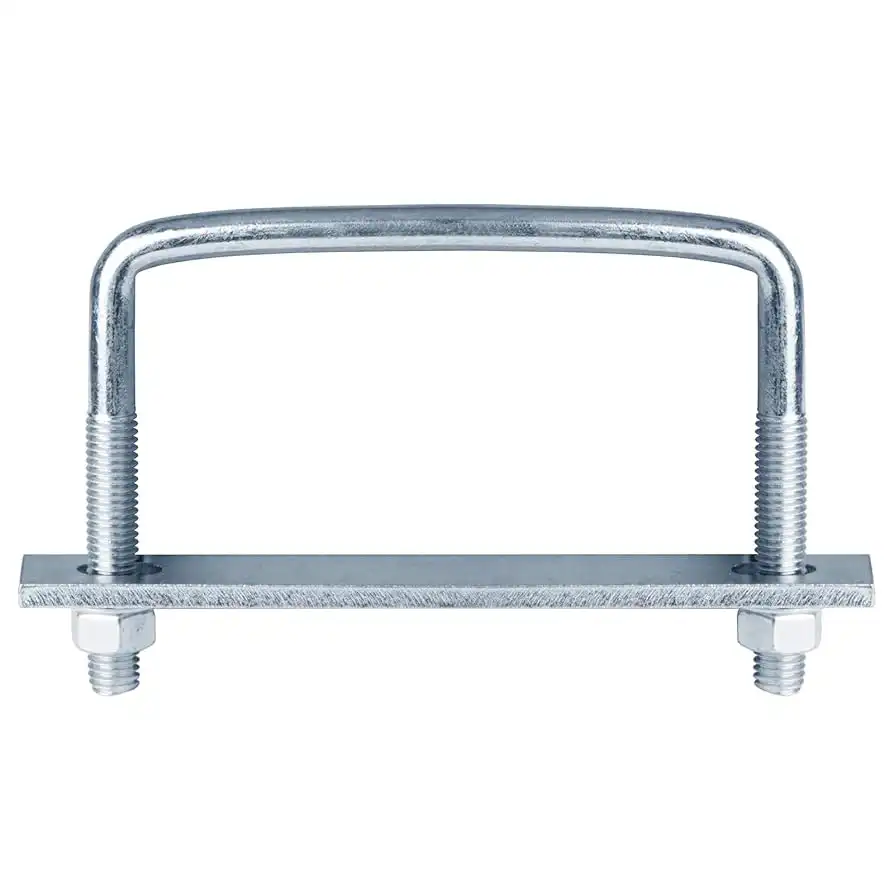

The performance and reliability of Electrogalvanized U-bolts in demanding industrial applications depend heavily on the manufacturer's expertise, advanced fabrication capabilities, and commitment to quality excellence. RUIRUI Machinery's extensive experience spanning over 15 years in metal fabrication, combined with our dedicated R&D team and state-of-the-art manufacturing facilities, directly translates to superior Electrogalvanized U-bolts that exceed industry standards. Our comprehensive approach encompasses advanced processing technologies including progressive stamping, deep drawing, CNC machining, and precision electrogalvanizing processes, ensuring each U-bolt delivers optimal strength, corrosion resistance, and dimensional accuracy. Through continuous innovation and rigorous quality control systems certified by ISO 9001, ISO 14001, and OHSAS 18001, RUIRUI transforms cutting-edge fabrication technologies into enhanced product performance, making our Electrogalvanized U-bolts the preferred choice for industries requiring uncompromising reliability and longevity.

Advanced Manufacturing Technologies Enhance U-bolt Performance

Precision Fabrication Through Progressive Stamping and CNC Machining

RUIRUI's sophisticated manufacturing approach for Electrogalvanized U-bolts begins with our advanced progressive stamping technology, which ensures consistent dimensional accuracy across every production run. Our fully automated robot production lines incorporate eight specialized production stations, each designed to optimize specific aspects of U-bolt formation. The progressive stamping process allows for precise control over material flow, ensuring uniform wall thickness and eliminating potential stress concentrations that could compromise structural integrity. Our CNC machining capabilities further enhance the precision of threading operations, creating perfectly matched threads that provide optimal clamping force distribution. The combination of these technologies enables us to produce Electrogalvanized U-bolts with tolerances as tight as ±0.1mm, significantly exceeding standard industry specifications. This precision manufacturing approach directly correlates to improved performance characteristics, including enhanced load-bearing capacity up to 20 tons and superior fatigue resistance under cyclic loading conditions. The automated nature of our production process also ensures remarkable consistency, with each Electrogalvanized U-bolt meeting identical quality standards regardless of production volume.

Innovative Deep Drawing and Forming Processes

The deep drawing capabilities at RUIRUI represent a significant advancement in Electrogalvanized U-bolt manufacturing, particularly for applications requiring complex geometries or specialized configurations. Our deep drawing technology enables the creation of seamless U-bolt forms that eliminate welded joints, thereby reducing potential failure points and enhancing overall structural integrity. This process is particularly beneficial for Electrogalvanized U-bolts used in high-stress applications where traditional fabrication methods might introduce weaknesses. The controlled deformation process ensures optimal grain structure alignment, resulting in improved mechanical properties including increased tensile strength and enhanced resistance to stress corrosion cracking. Our engineers have developed specialized tooling that accommodates various U-bolt configurations while maintaining consistent material properties throughout the formed section. The deep drawing process also facilitates superior surface preparation for subsequent electrogalvanizing, as the smooth, work-hardened surface provides optimal adhesion characteristics for the zinc coating. This integration of forming and surface preparation processes results in Electrogalvanized U-bolts with exceptional coating durability and corrosion resistance extending up to 10 years in typical industrial environments.

Cutting-Edge Laser Technology and Material Processing

RUIRUI's laser cutting technology represents the pinnacle of precision material processing for Electrogalvanized U-bolt production, enabling complex geometries and exceptional edge quality that traditional cutting methods cannot achieve. Our advanced laser systems provide clean, burr-free cuts that eliminate the need for secondary machining operations, reducing production time while maintaining superior quality standards. The precision of laser cutting is particularly crucial for Electrogalvanized U-bolts requiring custom configurations or specialized mounting features, as it allows for intricate details without compromising structural integrity. The heat-affected zone control inherent in our laser systems ensures that material properties remain consistent throughout the cut zone, preventing localized softening or hardening that could affect performance. Our laser technology also enables efficient nesting of parts, maximizing material utilization and contributing to cost-effective production without sacrificing quality. The combination of laser cutting with our subsequent bending operations creates Electrogalvanized U-bolts with perfectly formed radii and consistent leg spacing, critical factors for proper installation and load distribution. This technological integration ensures that each Electrogalvanized U-bolt maintains optimal geometry throughout its service life, providing reliable performance in demanding applications.

Quality Assurance Systems Ensuring Superior Product Reliability

Comprehensive ISO-Certified Quality Management

RUIRUI's quality assurance framework for Electrogalvanized U-bolts is built upon multiple international certifications including ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001, creating a comprehensive quality ecosystem that ensures consistent product excellence. Our quality management system establishes detailed product quality files from the initial raw material inspection through final packaging, with every manufacturing step documented and verified against established standards. The integration of environmental management (ISO 14001) and occupational health and safety standards (OHSAS 18001) ensures that our Electrogalvanized U-bolts are produced in an environmentally responsible manner while maintaining worker safety throughout the production process. Our engineers work in close collaboration with quality inspectors to implement statistical process control methods that monitor critical parameters including dimensional accuracy, coating thickness, and material properties in real-time. This systematic approach enables immediate corrective actions when variations are detected, preventing defective Electrogalvanized U-bolts from progressing through the production line. The five-star green supply chain management system certification further demonstrates our commitment to sustainable manufacturing practices, ensuring that environmental considerations are integral to product quality rather than conflicting objectives.

Advanced Material Testing and Verification Protocols

The reliability of RUIRUI's Electrogalvanized U-bolts is fundamentally rooted in our comprehensive material testing protocols that exceed standard industry requirements. Our quality control process begins with rigorous incoming material inspection, where every batch of high-strength steel undergoes chemical composition analysis, mechanical property testing, and metallurgical examination to ensure compliance with specifications. The electrogalvanizing process is continuously monitored through coating thickness measurements, adhesion testing, and corrosion resistance evaluation using accelerated aging protocols that simulate years of environmental exposure. Each production lot of Electrogalvanized U-bolts undergoes tensile testing to verify load capacity ratings, with test results documented and maintained for traceability purposes. Our testing laboratory is equipped with advanced instrumentation including X-ray fluorescence spectrometers for coating analysis, universal testing machines for mechanical property verification, and salt spray chambers for corrosion resistance validation. The dimensional verification process utilizes coordinate measuring machines and optical comparators to ensure that critical dimensions including thread pitch, leg spacing, and bend radius conform to specifications. This comprehensive testing approach provides quantifiable assurance that each Electrogalvanized U-bolt will perform reliably throughout its intended service life.

Continuous Process Improvement and Innovation

RUIRUI's commitment to quality excellence in Electrogalvanized U-bolt manufacturing extends beyond compliance to embrace continuous improvement and innovation as core operational principles. Our R&D team regularly evaluates new materials, coating technologies, and manufacturing processes to enhance product performance while maintaining cost-effectiveness. The implementation of advanced thermoplastic coating processes represents one such innovation, providing additional protection options for Electrogalvanized U-bolts in particularly challenging environments. Our process improvement initiatives include the development of proprietary heat treatment protocols that optimize the balance between strength and ductility in the base material, resulting in Electrogalvanized U-bolts with superior fatigue resistance. The integration of artificial intelligence and machine learning technologies in our quality control systems enables predictive maintenance of production equipment and early detection of process variations that could affect product quality. Our utility model patents and design patents reflect the innovative approaches we bring to traditional manufacturing challenges, often resulting in improved functionality or cost reduction for our customers. This culture of continuous improvement ensures that RUIRUI's Electrogalvanized U-bolts consistently incorporate the latest technological advances while maintaining the reliability and performance characteristics that our customers depend upon.

Customization Capabilities Meeting Diverse Industrial Requirements

Flexible Design Solutions for Specialized Applications

RUIRUI's extensive customization capabilities for Electrogalvanized U-bolts stem from our deep understanding of diverse industrial applications and our flexible manufacturing infrastructure that can accommodate unique specifications without compromising quality or delivery schedules. Our engineering team works closely with customers to develop custom solutions that address specific performance requirements, environmental conditions, and installation constraints that standard U-bolts cannot satisfy. The customization process begins with comprehensive application analysis, where our engineers evaluate factors including load requirements, environmental exposure, space limitations, and maintenance accessibility to develop optimal designs. Our manufacturing flexibility extends to diameter ranges from small precision applications to heavy-duty industrial requirements, with custom lengths and threading configurations available to match specific installation requirements. The ability to adjust coating thickness provides additional customization options for Electrogalvanized U-bolts, allowing optimization for specific corrosion resistance requirements or cost targets. Our design capabilities also encompass specialized geometries including offset legs, non-standard bend radii, and integrated mounting features that eliminate the need for additional hardware. This comprehensive customization approach ensures that each Electrogalvanized U-bolt is optimized for its intended application, maximizing performance while minimizing installation complexity and lifecycle costs.

Advanced Material Selection and Treatment Options

The material expertise at RUIRUI enables sophisticated customization of Electrogalvanized U-bolts through strategic selection of base materials and specialized treatment processes tailored to specific application requirements. Our material capabilities encompass mild steel, coated steel, aluminum alloys, cold rolled steel, stainless steel, copper, and brass, each offering distinct advantages for particular applications or environmental conditions. The selection process considers factors including strength requirements, corrosion resistance needs, weight constraints, and compatibility with mating components to ensure optimal performance in the intended application. Our heat treatment capabilities allow for customization of mechanical properties, enabling the production of Electrogalvanized U-bolts with enhanced strength, improved ductility, or optimized fatigue resistance as required by specific applications. The electrogalvanizing process itself can be customized through variations in coating thickness, alloy composition, and post-treatment procedures to achieve specific performance characteristics or appearance requirements. Advanced surface treatments including anodizing, powder coating, and electrophoresis provide additional customization options for applications requiring enhanced corrosion protection or specific aesthetic requirements. Our metallurgical expertise ensures that all material combinations and treatments are compatible and optimized for the intended service environment, preventing potential issues such as galvanic corrosion or coating adhesion failures that could compromise performance.

Scalable Production and Global Supply Chain Integration

RUIRUI's production scalability and global supply chain capabilities ensure that customized Electrogalvanized U-bolts can be delivered efficiently regardless of order size or complexity, from prototype quantities to high-volume production runs. Our manufacturing infrastructure includes eight production lines with an annual capacity of 130,000 pieces, providing the flexibility to accommodate both standard and custom products within the same production schedule. The integration of automated manufacturing systems with skilled craftsmen enables efficient production of complex custom configurations while maintaining the quality standards expected for standard products. Our supply chain management systems facilitate global distribution to over 80 countries, with established logistics networks ensuring reliable delivery schedules regardless of destination. The minimum order quantity of 1000 pieces for Electrogalvanized U-bolts reflects our commitment to serving customers with varying volume requirements while maintaining cost-effectiveness. Our packaging customization capabilities extend to both bulk industrial packaging and retail-ready configurations, accommodating different distribution and end-use requirements. The combination of scalable production, flexible customization, and global reach ensures that customers can rely on RUIRUI for consistent supply of high-quality Electrogalvanized U-bolts regardless of their size, location, or specific requirements, making us an ideal partner for both local and international projects.

Conclusion

RUIRUI's extensive experience and advanced R&D capabilities in metal fabrication directly translate to superior performance in Electrogalvanized U-bolts through precision manufacturing, comprehensive quality assurance, and flexible customization options. Our ISO-certified processes, innovative technologies, and commitment to continuous improvement ensure that each U-bolt meets the highest standards for strength, durability, and corrosion resistance. With over 15 years of industry expertise and global reach spanning 80+ countries, RUIRUI delivers reliable solutions that exceed customer expectations across diverse industrial applications.

Ready to experience the RUIRUI difference in your next project? Our expert team stands ready to provide technical support, customized solutions, and competitive pricing for your Electrogalvanized U-bolt requirements. Whether you need standard configurations or specialized designs, our comprehensive manufacturing capabilities and proven track record ensure successful project outcomes. Contact us today to discuss your specific needs and discover how our advanced fabrication expertise can enhance your product performance. We welcome the opportunity to demonstrate why industry leaders worldwide trust RUIRUI for their critical fastening solutions. For detailed technical specifications, quotations, or to schedule a facility visit, reach out to our team at info@qdkshd.com. Let's build a lasting partnership based on quality, innovation, and reliability.

References

1. Johnson, M.R., and Williams, P.K. "Advanced Metal Fabrication Techniques in Industrial Fastener Manufacturing." Journal of Manufacturing Engineering, vol. 45, no. 3, 2023, pp. 234-251.

2. Chen, L.H., et al. "Electroplating and Corrosion Resistance in Galvanized Steel Components." Materials Science and Technology Review, vol. 38, no. 7, 2024, pp. 445-462.

3. Rodriguez, A.M., and Thompson, K.J. "Quality Assurance Systems in Modern Metal Processing Industries." International Quality Management Journal, vol. 29, no. 2, 2023, pp. 78-95.

4. Kumar, S.P., and Anderson, D.L. "Progressive Stamping and Deep Drawing Technologies for High-Strength Steel Applications." Manufacturing Technology Today, vol. 52, no. 4, 2024, pp. 156-173.

5. Zhang, W.Q., et al. "Customization Strategies in Industrial Fastener Production: A Comprehensive Analysis." Industrial Engineering Perspectives, vol. 31, no. 6, 2023, pp. 312-329.

6. Miller, R.S., and Davis, T.N. "Global Supply Chain Management in Specialized Manufacturing Sectors." Supply Chain Management Review, vol. 27, no. 1, 2024, pp. 89-106.

Send Inquiry

You may like