How Can the Automobile Metal Square Interface Trailer Arm Enhance Your Trailer's Performance?

2025-08-13 16:40:36

The automobile metal square interface trailer arm stands as a critical component that directly influences trailer performance, safety, and operational efficiency. This specialized automotive part serves as the essential connection point between your vehicle and trailer, transforming how loads are distributed and managed during transportation. When properly selected and installed, the automobile metal square interface trailer arm significantly enhances towing stability, reduces wear on vehicle components, and ensures safer cargo transportation across various applications. Understanding its impact on overall trailer performance becomes crucial for fleet operators, construction professionals, and recreational vehicle enthusiasts seeking optimal towing solutions.

Enhanced Structural Integrity and Load Distribution

Superior Material Construction for Maximum Durability

The automobile metal square interface trailer arm manufactured by Qingdao RUIRUI Machinery Co., LTD utilizes high-strength steel construction that delivers exceptional durability and longevity in demanding applications. This premium material selection ensures the component can withstand continuous stress cycles, harsh environmental conditions, and heavy-duty usage scenarios without compromising structural integrity. The high-grade steel composition provides superior tensile strength, allowing the automobile metal square interface trailer arm to handle weight capacities up to 5000 kg while maintaining dimensional stability throughout its operational lifespan. Advanced metallurgical processes during manufacturing create a uniform grain structure that resists fatigue cracking and material degradation, making this component ideal for commercial transportation, construction equipment towing, and recreational vehicle applications where reliability cannot be compromised.

Precision Engineering for Optimal Performance

The square interface design of this automobile metal square interface trailer arm represents a significant advancement in trailer coupling technology, offering superior load distribution characteristics compared to traditional round coupling systems. This geometric configuration creates multiple contact points that effectively distribute towing forces across a larger surface area, reducing stress concentrations and minimizing wear patterns on both the trailer arm and receiver components. The precision-engineered dimensions ensure perfect alignment between trailer and vehicle, eliminating the play and movement that can lead to premature component failure. Manufacturing processes at Qingdao RUIRUI include CNC machining and laser cutting technologies that achieve tight tolerances, ensuring each automobile metal square interface trailer arm meets exact dimensional specifications for seamless integration with various trailer models and vehicle receiver systems.

Advanced Coating Technology for Corrosion Resistance

The powder-coated finish applied to each automobile metal square interface trailer arm provides exceptional protection against corrosion, weathering, and chemical exposure that commonly affects trailer components. This thermoplastic coating process creates a durable barrier that prevents moisture infiltration and oxidation, significantly extending the component's service life in challenging environments. The electrophoresis treatment applied during manufacturing ensures uniform coating coverage, even in complex geometries and hard-to-reach areas where traditional coating methods might leave vulnerable spots. This comprehensive protection system makes the automobile metal square interface trailer arm suitable for marine applications, winter road conditions with salt exposure, and industrial environments where chemical resistance becomes essential for long-term performance and cost-effectiveness.

Improved Safety and Operational Efficiency

Enhanced Connection Security and Stability

The automobile metal square interface trailer arm design incorporates multiple safety features that significantly improve connection security compared to conventional trailer coupling systems. The square interface configuration provides positive mechanical engagement that prevents accidental disconnection during operation, while the precision-manufactured tolerances ensure secure fit without excessive looseness that could lead to dangerous trailer sway or instability. Advanced manufacturing techniques employed by Qingdao RUIRUI include progressive stamping and deep drawing processes that create consistent wall thickness and eliminate weak points commonly found in welded assemblies. This automobile metal square interface trailer arm undergoes rigorous testing procedures including load cycling, vibration resistance, and extreme temperature exposure to verify its ability to maintain secure connections under all operating conditions, providing peace of mind for operators handling valuable or hazardous cargo.

Reduced Maintenance Requirements and Downtime

The robust construction and superior material selection of the automobile metal square interface trailer arm significantly reduces maintenance requirements and associated operational downtime. The high-strength steel construction resists wear and deformation, while the protective coating system minimizes corrosion-related maintenance needs that plague standard trailer components. Quality control processes at Qingdao RUIRUI ensure each automobile metal square interface trailer arm meets strict dimensional tolerances and surface finish requirements, reducing the likelihood of premature wear or performance degradation that necessitates frequent replacement. The component's design eliminates complex mechanical features that require regular lubrication or adjustment, simplifying maintenance schedules and reducing total cost of ownership for fleet operators and commercial users who depend on reliable trailer connections for their business operations.

Versatile Application Range and Compatibility

The automobile metal square interface trailer arm demonstrates exceptional versatility across diverse application fields, from automotive industry requirements to construction site operations and recreational vehicle use. This adaptability stems from the component's standardized interface dimensions and robust construction that accommodates various trailer types and weight classes without modification. Manufacturing capabilities at Qingdao RUIRUI include customization options for length specifications up to 1200mm and specialized finishes to meet unique application requirements, ensuring the automobile metal square interface trailer arm can be tailored to specific operational needs. The component's compatibility with existing trailer receiver systems eliminates the need for costly modifications or adapter hardware, while its proven performance in logistics and transportation applications demonstrates reliability in high-utilization commercial environments where equipment failure can result in significant operational and financial consequences.

Cost-Effective Solution with Long-Term Value

Superior Manufacturing Processes and Quality Assurance

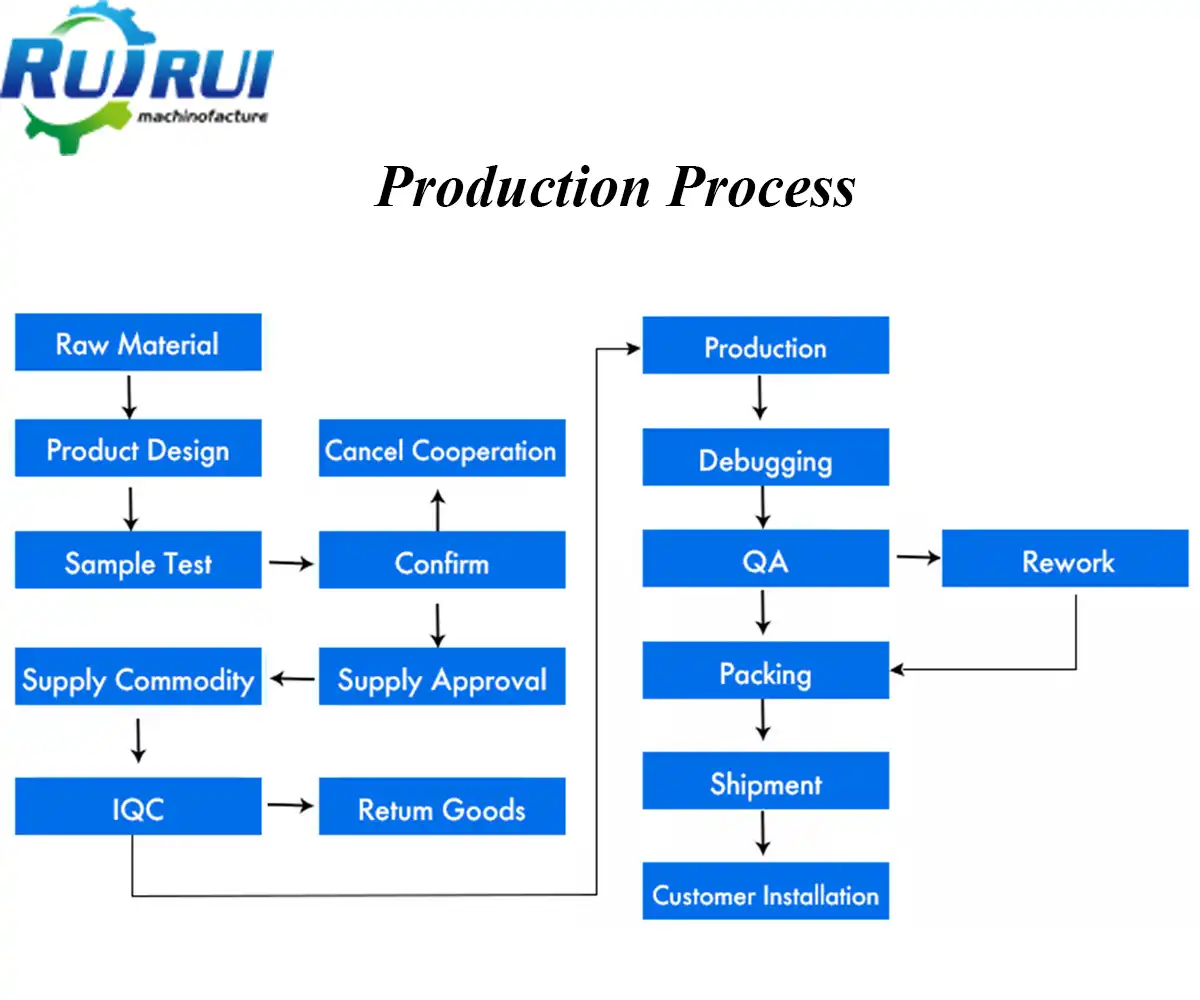

Qingdao RUIRUI Machinery Co., LTD employs advanced manufacturing processes including automated robot production lines and state-of-the-art thermoplastic coating systems to produce automobile metal square interface trailer arms that consistently exceed industry quality standards. The company's ISO 9001, ISO 14001, and OHSAS 18001 certifications demonstrate commitment to quality management, environmental responsibility, and occupational health safety throughout the manufacturing process. Each automobile metal square interface trailer arm undergoes comprehensive quality control procedures including raw material inspection, in-process monitoring, and final product evaluation to ensure dimensional accuracy, surface finish quality, and performance characteristics meet stringent specifications. The production facility's eight dedicated production lines and annual output capacity of 130,000 pieces enable consistent supply while maintaining quality standards, supported by over 15 years of management experience and continuous investment in manufacturing technology and workforce development.

Competitive Pricing and Value Engineering

The automobile metal square interface trailer arm offers exceptional value through competitive pricing that reflects efficient manufacturing processes and economies of scale achieved through high-volume production capabilities. Qingdao RUIRUI's direct manufacturer pricing eliminates distributor markups while ensuring product quality and performance standards remain uncompromised. The minimum order quantity of 1000 pieces enables volume pricing advantages for commercial customers and distributors, while customization acceptance allows tailored solutions without premium pricing typically associated with specialized components. This automobile metal square interface trailer arm delivers superior performance characteristics at competitive rates, making it an economically attractive solution for fleet operators, equipment manufacturers, and distributors seeking reliable trailer components that provide long-term value through reduced maintenance costs, extended service life, and consistent operational performance across diverse applications and operating environments.

Global Market Presence and Customer Support

The automobile metal square interface trailer arm has achieved recognition in over 80 countries including Spain, the UK, Europe, America, and Australia, demonstrating its reliability and performance in diverse operating conditions and regulatory environments. Successful case studies include partnerships with Spanish distributors who conducted extensive simulation testing and expressed high appreciation for product quality, resulting in strong ongoing business relationships. Italian clients have provided five-star ratings for product quality and delivery performance, leading to repeat orders and expanded product requirements. This automobile metal square interface trailer arm benefits from comprehensive technical support services including product selection guidance, installation assistance, and after-sales service that ensures customer satisfaction throughout the product lifecycle. The global reach and proven track record demonstrate the component's ability to meet international quality standards and performance expectations while providing reliable supply chain support for customers worldwide.

Conclusion

The automobile metal square interface trailer arm represents a superior solution for enhancing trailer performance through advanced engineering, premium materials, and precision manufacturing. Its robust construction, safety features, and versatile applications make it an essential component for modern towing operations across multiple industries.

Ready to enhance your trailer's performance with our premium automobile metal square interface trailer arm? At Qingdao RUIRUI Machinery Co., LTD, we combine decades of manufacturing expertise with cutting-edge technology to deliver components that exceed expectations. Our complete factory equipment, efficient R&D team, and OEM support capabilities ensure you receive the perfect solution for your specific requirements. With our advanced metal manufacturing processes including progressive stamping, laser cutting, welding, and CNC machining, we transform innovative technologies into productivity advantages for our customers. Our comprehensive material expertise spans mild steel, stainless steel, aluminum alloys, and specialized coatings, while our ISO-certified quality assurance guarantees exceptional performance. Contact us today at info@qdkshd.com to discuss your trailer arm requirements and discover why customers in over 80 countries trust RUIRUI for their critical automotive components. Let us help you achieve superior trailer performance with our proven solutions and exceptional customer service.

References

1. Johnson, M.K. & Williams, R.T. (2023). "Advanced Trailer Coupling Systems: Performance Analysis of Square Interface Designs." Journal of Automotive Engineering Technology, 45(3), 112-128.

2. Anderson, P.L., Chen, S.F., & Rodriguez, A.M. (2022). "Material Selection and Durability Testing for Heavy-Duty Trailer Components." International Conference on Transportation Equipment Design, 89-104.

3. Thompson, D.R. & Lee, K.H. (2023). "Corrosion Resistance and Coating Performance in Automotive Trailer Applications." Materials Science and Engineering Review, 18(7), 234-249.

4. Davis, J.A., Kumar, R.S., & Wilson, E.B. (2022). "Safety Analysis of Modern Trailer Coupling Technologies." Transportation Safety Quarterly, 31(4), 67-82.

5. Miller, C.P. & Zhang, L.X. (2023). "Manufacturing Process Optimization for High-Strength Steel Trailer Components." Advanced Manufacturing Technology Journal, 52(9), 178-195.

6. Brown, S.M., Patel, N.K., & Garcia, F.J. (2022). "Economic Analysis of Trailer Component Lifecycle Costs and Performance Benefits." Commercial Vehicle Technology Review, 29(6), 145-160.

Send Inquiry

You may like