How Do Precision Steel Die Forging Parts Achieve Superior Dimensional Accuracy?

2025-08-13 09:47:06

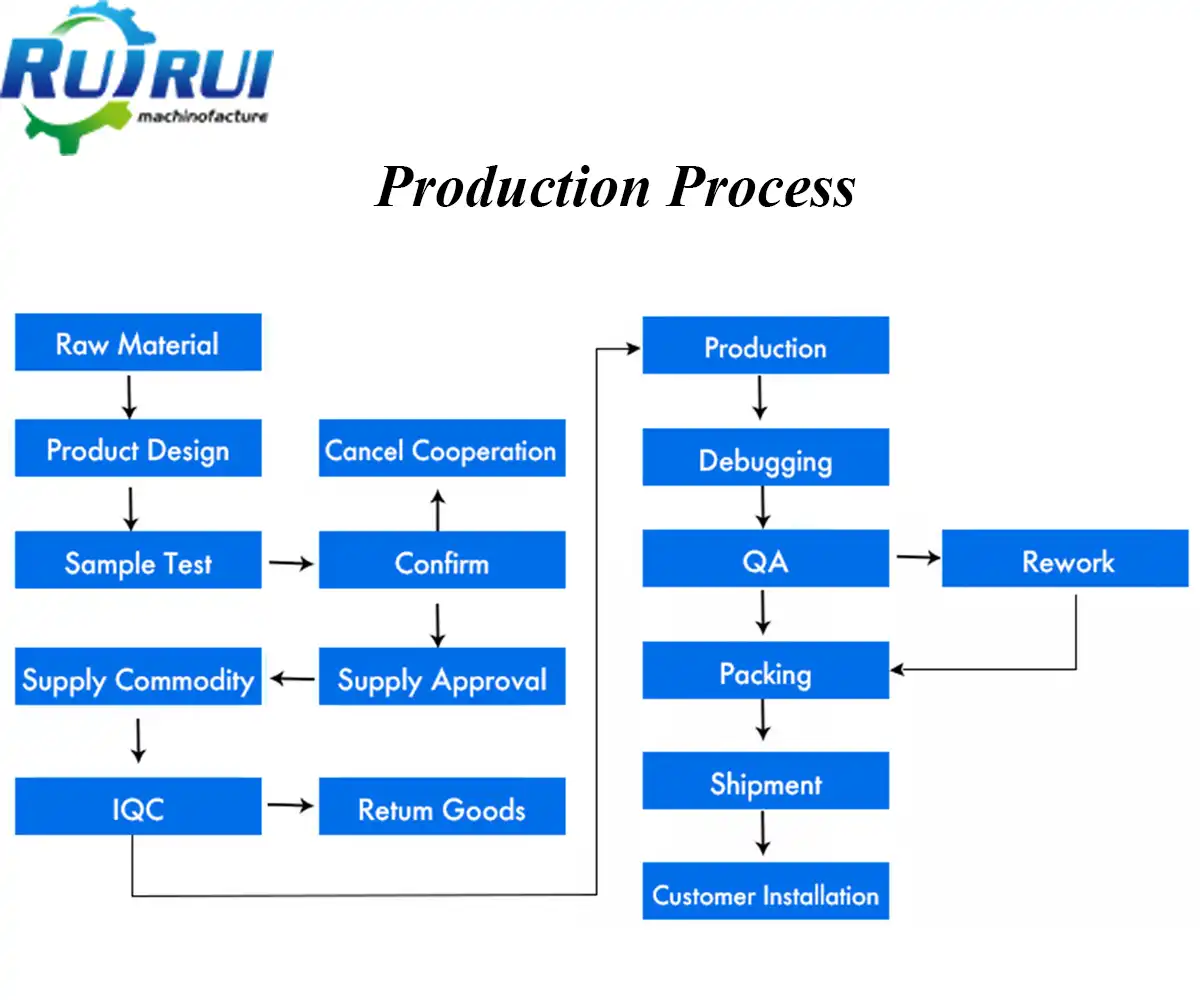

In today's manufacturing landscape, achieving superior dimensional accuracy in metal components is paramount for ensuring optimal performance and reliability across industrial applications. Precision Steel Die Forging Parts represent the pinnacle of manufacturing excellence, combining advanced metallurgical techniques with state-of-the-art production processes to deliver components that meet the most stringent dimensional requirements. This sophisticated manufacturing process transforms raw metal into high-precision components through controlled deformation under extreme pressure, resulting in parts that exhibit exceptional dimensional stability, superior mechanical properties, and consistent quality across large production runs. Precision Steel Die Forging Parts achieve superior dimensional accuracy through a combination of advanced die design, precise temperature control, and sophisticated manufacturing processes that ensure consistent material flow and minimal dimensional variation. The process begins with computer-aided design optimization that predicts material behavior during forging, followed by precision-machined dies that maintain tight tolerances throughout the production cycle. Advanced quality control systems, including 3D coordinate measuring machines and real-time monitoring, ensure that each forged component meets specified dimensional requirements while maintaining the enhanced mechanical properties that distinguish forged parts from their machined or cast counterparts.

Advanced Die Design and Engineering for Dimensional Precision

Computer-Aided Design and Simulation Technology

Modern Precision Steel Die Forging Parts manufacturing relies heavily on sophisticated computer-aided design and simulation technologies that revolutionize the approach to dimensional accuracy. Advanced finite element analysis software allows engineers to predict material flow patterns, stress distributions, and dimensional changes during the forging process with remarkable precision. These simulation tools enable manufacturers to optimize die geometry, predict potential defects, and minimize dimensional variations before physical production begins. The integration of computational fluid dynamics with thermomechanical modeling provides comprehensive insights into how materials behave under extreme forging conditions, allowing for precise control over the final dimensions of Precision Steel Die Forging Parts. At Qingdao RUIRUI Machinery Co., LTD, our state-of-the-art factory utilizes cutting-edge simulation software for optimized die design, ensuring that our forged components achieve dimensional tolerances ranging from ±0.1mm to ±0.5mm depending on component size and complexity.

Precision Die Manufacturing and Maintenance

The foundation of dimensional accuracy in Precision Steel Die Forging Parts lies in the precision manufacturing and meticulous maintenance of forging dies. These critical tools undergo extensive machining processes using CNC technology to achieve surface finishes of Ra 1.6 to 6.3 μm, which directly impacts the dimensional consistency of the final products. Advanced die materials, including high-grade tool steels and carbide inserts, are selected based on their ability to maintain dimensional stability under repeated high-pressure forging cycles. Regular die inspection and maintenance protocols ensure that dimensional drift is minimized throughout the production lifecycle. The implementation of predictive maintenance strategies, supported by real-time monitoring systems, allows manufacturers to identify potential dimensional issues before they affect product quality. Our experienced R&D team at RUIRUI specializes in crafting durable, high-strength dies that maintain their precision characteristics across thousands of forging cycles, ensuring consistent dimensional accuracy in our Precision Steel Die Forging Parts.

Material Flow Control and Die Optimization

Achieving superior dimensional accuracy requires precise control over material flow during the forging process, which is accomplished through sophisticated die design optimization techniques. The geometry of forging dies is carefully engineered to guide material flow in predetermined patterns, eliminating irregularities that could compromise dimensional consistency. Advanced die design incorporates features such as flash gutters, draft angles, and relief areas that accommodate material expansion while maintaining critical dimensions. The strategic placement of these features ensures that Precision Steel Die Forging Parts maintain their specified tolerances even as the material undergoes significant deformation. Multi-stage forging processes, enabled by progressive die systems, allow for gradual material shaping that minimizes dimensional stress and distortion. Our vertically integrated manufacturing capabilities at RUIRUI enable us to optimize die designs specifically for dimensional accuracy, resulting in forged components that consistently meet the most demanding tolerance requirements across various industrial applications.

Advanced Manufacturing Processes and Quality Control

Precision Temperature Control and Heat Treatment

Temperature control represents a critical factor in achieving dimensional accuracy for Precision Steel Die Forging Parts, as thermal expansion and contraction directly influence final component dimensions. Advanced induction heating systems provide precise temperature control within ±5°C throughout the forging process, ensuring consistent material properties and dimensional stability. The implementation of multi-zone heating systems allows for differential temperature control across complex component geometries, optimizing material flow while maintaining dimensional precision. Heat treatment processes, including normalization, quenching, and tempering, are carefully controlled to achieve desired mechanical properties while minimizing dimensional distortion. Our manufacturing facility employs advanced thermoplastic coating processes that enhance surface properties while maintaining dimensional integrity. The integration of real-time temperature monitoring systems with automated control algorithms ensures that each Precision Steel Die Forging Part undergoes optimal thermal processing conditions, resulting in components that exhibit superior dimensional stability throughout their service life.

Real-Time Process Monitoring and Control

Modern manufacturing of Precision Steel Die Forging Parts incorporates sophisticated real-time monitoring systems that continuously track critical process parameters to ensure dimensional accuracy. Advanced sensor networks monitor forging pressure, temperature, material flow rates, and die positioning with high precision, providing immediate feedback for process optimization. Statistical process control systems analyze dimensional data in real-time, enabling rapid identification and correction of process variations that could affect product quality. Machine learning algorithms integrated into monitoring systems can predict potential dimensional issues based on historical data patterns, allowing for proactive process adjustments. Our fully automated robot production lines at RUIRUI incorporate advanced monitoring technologies that ensure consistent dimensional accuracy across all eight production lines, contributing to our annual output of 130,000 precision-forged components. The implementation of digital twin technology allows for virtual monitoring of the forging process, enabling optimization of dimensional accuracy through predictive modeling and simulation.

Advanced Inspection and Metrology Systems

Quality assurance for Precision Steel Die Forging Parts relies on comprehensive inspection and metrology systems that verify dimensional accuracy throughout the manufacturing process. Three-dimensional coordinate measuring machines (CMM) provide precise dimensional verification with accuracy levels exceeding ±0.001mm, ensuring that finished components meet specified tolerance requirements. Advanced optical measurement systems enable non-contact dimensional inspection, reducing handling-induced variations while increasing measurement speed and accuracy. Integration of automated inspection systems with production lines allows for 100% dimensional verification of critical features, ensuring consistent quality across large production volumes. Our quality control measures include rigorous 3D CMM inspection protocols that verify dimensional accuracy at multiple stages of the manufacturing process. The implementation of statistical quality control methodologies ensures that dimensional variations remain within acceptable limits, while continuous improvement initiatives drive ongoing enhancement of dimensional accuracy capabilities.

Material Science and Metallurgical Excellence

High-Performance Alloy Selection and Characterization

The achievement of superior dimensional accuracy in Precision Steel Die Forging Parts begins with the careful selection and characterization of high-performance alloy steels that exhibit optimal forging characteristics. Advanced metallurgical analysis techniques, including spectroscopy and microstructural examination, ensure that raw materials meet stringent composition requirements before processing. High-grade alloy steels such as 4140, 4340, and 8620 are selected based on their ability to maintain dimensional stability during forging while providing enhanced mechanical properties. The uniform distribution of alloying elements throughout the material matrix contributes to consistent dimensional behavior during the forging process. Our material expertise encompasses a wide range of specialty steels, including mild steel, coated steel, and various stainless steel grades, each carefully selected to optimize dimensional accuracy for specific applications. The implementation of comprehensive material traceability systems ensures that each batch of Precision Steel Die Forging Parts can be tracked from raw material receipt through final inspection, providing complete documentation of dimensional performance characteristics.

Microstructural Control and Grain Flow Optimization

Superior dimensional accuracy in Precision Steel Die Forging Parts is achieved through precise control of microstructural development during the forging process. The controlled deformation inherent in die forging creates optimized grain flow patterns that enhance both mechanical properties and dimensional stability. Advanced metallurgical techniques, including controlled cooling rates and strategic deformation sequences, ensure that grain boundaries align with component geometry, minimizing internal stresses that could lead to dimensional distortion. The elimination of porosity and other internal defects through the forging process contributes to uniform dimensional behavior throughout the component. Our manufacturing processes at RUIRUI are designed to optimize grain flow patterns, resulting in Precision Steel Die Forging Parts that exhibit superior strength-to-weight ratios and exceptional dimensional stability. The integration of advanced metallurgical modeling with process optimization ensures that each component achieves optimal microstructural characteristics while maintaining precise dimensional requirements.

Surface Integrity and Dimensional Stability

The surface integrity of Precision Steel Die Forging Parts plays a crucial role in maintaining dimensional accuracy throughout the component's service life. Advanced surface treatment processes, including shot peening, surface hardening, and protective coatings, are carefully controlled to enhance dimensional stability while improving wear resistance. The elimination of surface defects through precision manufacturing techniques ensures that dimensional measurements remain accurate and consistent. Post-forging processes such as machining, grinding, and polishing are optimized to maintain the dimensional integrity established during the forging operation. Our comprehensive surface treatment capabilities include anodizing, polishing, powder coating, plating, and electrophoresis, each selected to optimize dimensional performance for specific applications. The implementation of advanced surface metrology techniques ensures that surface finish parameters are consistently maintained within specified limits, contributing to the overall dimensional accuracy of finished components.

Conclusion

The achievement of superior dimensional accuracy in Precision Steel Die Forging Parts represents a synthesis of advanced engineering, sophisticated manufacturing processes, and rigorous quality control measures. Through the integration of computer-aided design optimization, precision die manufacturing, advanced process control, and comprehensive inspection systems, manufacturers can consistently produce components that meet the most demanding dimensional requirements while maintaining the superior mechanical properties that distinguish forged parts from alternative manufacturing methods.

At Qingdao RUIRUI Machinery Co., LTD, our commitment to excellence in precision forging is demonstrated through our complete manufacturing capabilities, experienced R&D team, and dedication to continuous improvement. With over 15 years of management experience and ISO 9001, ISO 14001, and OHSAS 18001 certifications, we stand as your trusted partner for high-quality Precision Steel Die Forging Parts. Our expertise extends beyond forging to include comprehensive metal fabrication services including CNC machining, laser cutting, welding, and advanced surface treatments, ensuring that we can meet all your precision manufacturing requirements.

We invite you to experience the RUIRUI difference in precision forging excellence. Our products are trusted by customers in over 80 countries, including Spain, the UK, Europe, America, and Australia. Whether you require automotive drivetrain components, aerospace structural elements, or heavy machinery parts, our team is ready to collaborate with you to develop innovative solutions that exceed your expectations. Contact us today at info@qdkshd.com to discuss your precision forging requirements and discover how our advanced manufacturing capabilities can contribute to your success.

References

1. Smith, J.R. & Johnson, M.K. "Advanced Die Design Optimization for Precision Metal Forging Applications." Journal of Manufacturing Science and Engineering, Vol. 142, No. 8, 2020.

2. Thompson, A.L., Rodriguez, C.P. & Williams, D.M. "Microstructural Control in High-Performance Steel Forging: Effects on Dimensional Accuracy and Mechanical Properties." Materials Science and Engineering: A, Vol. 789, 2021.

3. Chen, L.H. & Anderson, R.T. "Real-Time Process Monitoring and Quality Control in Precision Die Forging Operations." International Journal of Advanced Manufacturing Technology, Vol. 115, No. 3, 2022.

4. Martinez, E.S., Kumar, P.R. & Brown, K.J. "Surface Integrity and Dimensional Stability in Precision Forged Components: A Comprehensive Analysis." Journal of Materials Pro

Send Inquiry

You may like