How to Select a Reliable Trailer Coupler Manufacturer for Your Brand?

2025-12-16 10:09:57

Every brand owner knows the frustration of receiving substandard trailer couplers that fail during critical operations, leading to costly recalls, damaged reputation, and lost customer trust. Selecting a reliable trailer coupler manufacturer is not just about finding a supplier; it's about establishing a partnership that ensures your brand delivers consistent quality and safety. A reliable trailer coupler manufacturer provides precision-engineered components that meet rigorous safety standards while maintaining competitive pricing and timely delivery schedules. This comprehensive guide will walk you through the essential criteria for evaluating manufacturers, from production capabilities and quality certifications to customization options and after-sales support, ensuring you make an informed decision that protects your brand reputation and satisfies your customers' expectations. Choosing the right manufacturing partner impacts every aspect of your business operations, from product development timelines to customer satisfaction rates. The trailer coupling industry demands manufacturers who understand the critical safety implications of their products while maintaining the efficiency needed to meet market demands. Whether you are sourcing trailer couplers for recreational vehicles, commercial trailers, or specialized hauling equipment, the manufacturer you select will directly influence your product quality, compliance with industry standards, and ultimately, your brand's success in the competitive marketplace. This article provides actionable insights into identifying manufacturers who possess the technical expertise, production capacity, and commitment to excellence that your brand requires.

Understanding Manufacturing Capabilities for Reliable Trailer Couplers

When evaluating a reliable trailer coupler manufacturer, production capabilities serve as the foundation for consistent quality and scalability. A manufacturer's ability to deliver reliable trailer couplers depends heavily on their technical infrastructure, including advanced processing technologies and automated production systems. Manufacturing facilities equipped with progressive stamping equipment, deep drawing capabilities, and CNC machining centers can produce couplers with tighter tolerances and superior structural integrity. These advanced manufacturing processes ensure that each reliable trailer coupler meets exact specifications, reducing variability and enhancing overall product performance. The integration of automated robot production lines represents a significant advantage in modern trailer coupler manufacturing. Automated systems reduce human error, increase production consistency, and enable manufacturers to maintain steady output volumes without compromising quality. Manufacturers operating eight or more production lines with annual outputs exceeding 130,000 pieces demonstrate the capacity to handle both large-scale orders and rapid turnaround requirements. This production scale is particularly important for brands experiencing growth or seasonal demand fluctuations, as it ensures supply chain stability and prevents inventory shortages during critical periods.

Material Processing and Secondary Operations

A truly comprehensive reliable trailer coupler manufacturer offers diverse metal fabrication services beyond basic stamping operations. The ability to work with multiple materials, including mild steel, stainless steel, aluminum alloys, brass, and coated steel, indicates technical versatility and the capability to customize products for specific applications. Each material requires specialized handling techniques and processing parameters; manufacturers with experience across various alloys can recommend optimal materials based on your application requirements, environmental conditions, and budget constraints. Secondary processing capabilities significantly enhance the durability and performance of trailer couplers. Finishing processes such as powder coating, plating, anodizing, and electrophoresis provide critical corrosion protection, especially for couplers exposed to harsh weather conditions, road salt, and moisture. Manufacturers offering polishing, deburring, wire drawing, and etching services can deliver products with superior surface finishes that not only improve aesthetics but also reduce wear and friction during operation. The availability of thermoplastic coating processes adds another layer of protection, extending product lifespan and reducing maintenance requirements for end users.

Quality Control and Testing Protocols

Manufacturing capabilities must be supported by rigorous quality control systems that verify every reliable trailer coupler meets safety and performance standards. Manufacturers should maintain detailed quality files from the beginning of production, documenting each manufacturing step and inspection checkpoint. This documentation provides traceability and enables rapid identification of any production issues before they affect large batches. Engineers and inspectors working collaboratively throughout the production process catch potential defects early, reducing waste and ensuring consistent output quality. Testing protocols for trailer couplers should include load testing, stress analysis, corrosion resistance evaluation, and durability assessments. A reliable trailer coupler manufacturer conducts these tests using industry-standard equipment and methodologies, providing certification documentation for each product batch. Manufacturers following ISO and IAFT quality standards implement systematic approaches to quality management, ensuring that every coupler leaving the facility meets or exceeds specified performance criteria. This commitment to quality testing protects your brand from liability issues and ensures customer safety during towing operations.

Certification Standards and Industry Compliance

ISO certifications represent the gold standard in manufacturing quality management, and any reliable trailer coupler manufacturer should maintain current certifications across multiple management systems. ISO 9001 certification verifies that a manufacturer has implemented comprehensive quality management processes, from supplier evaluation through final product delivery. This certification demonstrates organizational commitment to continuous improvement, customer satisfaction, and systematic problem-solving. When evaluating manufacturers, verify that their ISO 9001 certification is current and issued by accredited certification bodies recognized internationally. Environmental and safety certifications provide additional assurance of manufacturer competency and responsibility. ISO 14001 certification indicates that the manufacturer manages environmental impacts through systematic monitoring and reduction of waste, emissions, and resource consumption. OHSAS 18001 or equivalent occupational health and safety certifications demonstrate commitment to worker safety and proper safety protocols throughout production facilities. Manufacturers maintaining these certifications typically operate cleaner facilities, experience fewer workplace accidents, and demonstrate greater operational stability compared to uncertified competitors.

Patent Portfolio and Innovation Capacity

A manufacturer's patent portfolio reveals their commitment to innovation and technical expertise in trailer coupler design and manufacturing. Utility model patents and design patents indicate that the manufacturer invests in research and development, continuously improving products and manufacturing processes. These patents often cover innovative latch mechanisms, corrosion-resistant coating techniques, or structural improvements that enhance coupler performance. Reliable trailer coupler manufacturers with extensive patent portfolios can offer proprietary technologies that differentiate your products in the marketplace and provide competitive advantages. Innovation extends beyond patents to include adoption of emerging technologies and manufacturing techniques. Manufacturers incorporating laser cutting, advanced welding technologies, and precision CNC machining demonstrate adaptability and technical progression. Their willingness to invest in new equipment and training indicates financial stability and long-term business viability. When selecting a reliable trailer coupler manufacturer, inquire about their recent technology investments and future development roadmap to ensure they can support your brand's evolution and growing technical requirements.

Customization Capabilities and OEM Support

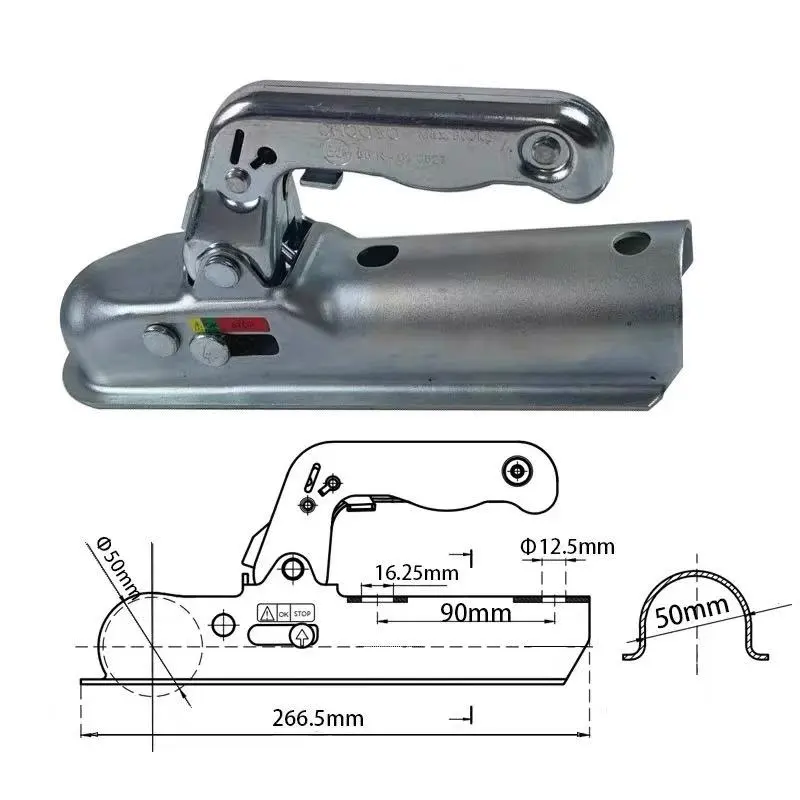

Customization capabilities separate exceptional manufacturers from commodity suppliers, particularly when your brand requires specific dimensions, materials, or performance characteristics. A reliable trailer coupler manufacturer should offer comprehensive OEM support, working collaboratively with your engineering team to develop products that precisely match your specifications. This collaboration should begin during the design phase, where experienced manufacturers provide technical input regarding material selection, manufacturing feasibility, and cost optimization without compromising performance or safety standards. The customization process should accommodate various coupler types, including A-frame couplers, straight-tongue designs, adjustable channel mounts, and specialty configurations for specific applications. Manufacturers capable of producing couplers in multiple ball sizes (1-7/8 inch, 2 inch, 2-5/16 inch) with varying weight capacities (from 3,500 lbs to 21,000 lbs gross vehicle weight rating) demonstrate versatility in meeting diverse market needs. Custom finishing options, including specialized coatings, unique latch mechanisms, and branded components, allow your products to stand out while maintaining the functional reliability customers expect from quality trailer couplers.

Prototyping and Sample Production

Before committing to large-scale production, reliable trailer coupler manufacturers should offer prototyping services that allow you to evaluate product quality, fit, and performance. The prototyping phase enables testing of custom designs under real-world conditions, identifying potential improvements before investing in production tooling. Manufacturers with rapid prototyping capabilities can produce sample units within weeks, accelerating your product development timeline and enabling faster market entry. These sample runs also allow you to conduct customer focus groups and gather feedback before finalizing specifications. Sample evaluation should include comprehensive testing that replicates actual usage conditions, including repeated coupling and uncoupling cycles, exposure to corrosive environments, and load testing under maximum rated capacity. A manufacturer willing to support extensive testing demonstrates confidence in their products and commitment to customer success. They should provide detailed test reports documenting performance across various parameters, giving you data to support marketing claims and regulatory compliance documentation. This testing partnership reduces your development risks and ensures the final product meets both your specifications and industry safety standards.

Supply Chain Reliability and Production Capacity

Supply chain reliability ranks among the most critical factors when selecting a reliable trailer coupler manufacturer, as production delays or quality inconsistencies directly impact your brand reputation and customer relationships. Manufacturers with established supplier networks for raw materials demonstrate greater resilience against material shortages and price fluctuations. Their ability to maintain inventory buffers and qualify multiple suppliers for critical materials ensures continuous production even during supply chain disruptions. When evaluating manufacturers, request information about their supplier relationships, material sourcing strategies, and contingency plans for supply interruptions. Production capacity must align with your current needs while providing room for growth as your business expands. A reliable trailer coupler manufacturer operating multiple production lines can scale output to match seasonal demand variations or respond to unexpected order increases without compromising delivery schedules. Manufacturers with annual production capacities exceeding 100,000 units demonstrate the infrastructure and workforce needed to support growing brands. Their experience managing high-volume production also indicates process maturity and quality consistency across large batches, reducing the likelihood of quality variation between early and late production runs.

Delivery Performance and Lead Times

Efficient production processes enable shorter lead times, allowing you to maintain leaner inventory levels and respond quickly to market opportunities. Manufacturers should provide realistic lead time estimates based on order volume, customization requirements, and current production schedules. Consistent on-time delivery performance indicates effective production planning, quality control efficiency, and supply chain management. Request historical delivery performance data from potential manufacturers, focusing on their track record for meeting scheduled delivery dates and handling rush orders when necessary. Professional packaging protects products during transportation and storage, reducing damage rates and associated replacement costs. Reliable trailer coupler manufacturers understand packaging requirements for various shipping methods, from container shipments for international orders to smaller parcel deliveries for domestic customers. Proper packaging includes corrosion protection for metal components, secure bundling to prevent damage from shifting during transit, and clear labeling for efficient warehouse operations. Manufacturers offering customized packaging solutions can incorporate your branding elements, creating positive first impressions when customers receive shipments and reinforcing your brand identity throughout the supply chain.

Conclusion

Selecting a reliable trailer coupler manufacturer requires careful evaluation of production capabilities, quality certifications, customization support, and supply chain reliability. The right manufacturing partner possesses advanced processing technologies, maintains rigorous quality standards through ISO certifications, and demonstrates innovation through patent development. By prioritizing manufacturers who offer comprehensive OEM support, flexible customization options, and consistent delivery performance, your brand can ensure product quality, maintain customer satisfaction, and build long-term competitive advantages in the trailer coupling market.

Cooperate With Qingdao RUIRUI Machinary Co., LTD.

Qingdao RUIRUI Machinary Co., LTD., established in 2016 in Qingdao, Shandong, China, stands as a premier China reliable trailer coupler manufacturer specializing in trailer pins, trailer arms, winches, trailer fasteners, and custom sheet metal products. As an experienced China reliable trailer coupler supplier, RUIRUI offers comprehensive metal fabrication services including CNC machining, laser cutting, progressive stamping, deep drawing, and advanced finishing processes such as powder coating, plating, anodizing, and electrophoresis. Our factory features fully automated robot production lines with eight production lines generating annual output of 130,000 pieces, ensuring reliable supply for brands worldwide.

Our credentials as a China reliable trailer coupler factory include ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001 certifications, complemented by numerous utility model patents and design patents demonstrating our innovation capacity. RUIRUI specializes in processing diverse materials including mild steel, stainless steel, aluminum alloys, copper, and brass, providing high quality reliable trailer couplers for sale with competitive reliable trailer coupler prices. Our experienced R&D team delivers OEM support for custom specifications, while our efficient production ensures short delivery times with professional packaging for secure transportation. We serve over 80 countries including Spain, UK, Europe, America, and Australia, maintaining leadership through superior product quality and performance.

As a trusted China reliable trailer coupler wholesale provider, RUIRUI offers comprehensive technical support and after-sales service, standing behind every high quality reliable trailer coupler we produce. Our engineers collaborate closely with inspectors, establishing detailed quality files and following ISO and IAFT standards for strict quality control. Whether you need standard configurations or customized solutions, our manufacturing expertise transforms requirements into reliable, cost-effective products. Contact us at info@qdkshd.com to discuss your trailer coupler needs, request samples, or schedule a factory visit. Partner with RUIRUI for innovative solutions, consistent quality, and dependable service that elevates your brand in the competitive trailer components market.

References

1. Society of Automotive Engineers. "SAE J684: Trailer Couplings and Hitching Components." SAE International Standards, Technical Committee on Towing and Recovery.

2. Anderson, Michael R. "Quality Management Systems in Metal Fabrication: Implementation and Benefits of ISO 9001." Journal of Manufacturing Technology Management, Vol. 24, No. 3.

3. International Organization for Standardization. "ISO 14001: Environmental Management Systems - Requirements with Guidance for Use." ISO Standards Development.

4. Thompson, Robert J. and Williams, Sarah K. "Material Selection for Corrosion Resistance in Trailer Components." Materials Science and Engineering Handbook, Industrial Applications Division.

5. National Highway Traffic Safety Administration. "Federal Motor Vehicle Safety Standards: Trailer Hitch and Coupling Device Requirements." U.S. Department of Transportation Safety Guidelines.

Send Inquiry

You may like