Introduction To Sheet Metal Processes

2026-03-02 09:53:45

Introduction To Sheet Metal Processes

Qingdao Ruirui Machinery Manufacturing Co., Ltd. has been deeply engaged in the field of metal manufacturing for many years, and has established a good reputation in the industry with advanced technology, sophisticated equipment and professional team. The company always adheres to the concept of quality first, innovation and development, and is committed to providing customers with high-quality metal manufacturing products and services.

Sheet metal process:

Process Overview: The sheet metal process is a comprehensive cold working process for sheet metal (usually < 6mm). The company's sheet metal process covers a series of operations such as shearing, punching/cutting/laminating, folding, welding, riveting, splicing, forming, etc., and can ensure the consistency of the thickness of the same part.

Equipment support: The company supports customized sheet metal. Equipped with advanced sheet metal processing equipment, such as high-precision shearing machines, it can accurately cut metal sheets of various specifications, with a maximum width of up to 2500 mm and a material thickness range of 0.8 - 30 mm; CNC punching machine can efficiently complete the punching task of various complex shapes, and can also deal with the processing of special-shaped workpieces and irregular holes; The laser cutting machine has the advantage of no tool restriction and flat section. In addition, there are press brakes that can precisely bend sheet metal into the desired angle and shape according to the requirements of the drawing.

Process:

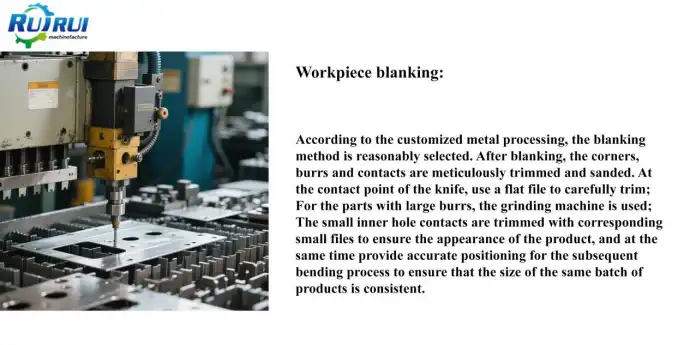

Next process:

The workpiece enters different processes according to the processing requirements. The bending process follows the principle of first inside and then outside, first small and then large, first special and then ordinary. If there is a workpiece with a crushed edge, it is bent to 30° - 40° and then crushed with a leveling die. Select the appropriate mold according to the height of the stud, and accurately adjust the pressure of the press to ensure that the stud is flush with the surface of the workpiece, so as to avoid the situation that the pressure is not firm or the pressure exceeds the surface of the workpiece.

The welding process is rich and diverse, including argon arc welding, spot welding, carbon dioxide shielded welding, manual arc welding, etc. In order to make the weld stronger, a bump is made at the weld of the workpiece, and the preload time, holding time, holding time and rest time are precisely adjusted.

Surface Treatment:

Different plates are treated in different ways, and the surface is usually electroplating after cold plate processing, phosphating treatment is carried out after electroplating, and finally spraying; The electroplating plate is first cleaned and degreased, and then sprayed; If the stainless steel plate is a mirror panel, a fog panel, or a wire drawing plate. Surface pretreatment can effectively clean the surface and significantly improve the adhesion and corrosion resistance of the coating film.

Spraying treatment:

Some customized sheet metal products need to be protected, and for workpieces with high surface requirements, they need to be scraped before spraying; The grounding symbol is protected with a special high-temperature sticker. When spraying, the workpiece is first hung on the assembly line, blown off the surface dust with a gas pipe, then enters the spraying area for spraying, then enters the drying area, and finally takes off from the assembly line.

Packing:

After the assembled workpiece is inspected and qualified, it is packed into a special packaging bag for protection. For custom sheet metal parts without special packaging, bubble wrap is used. For large quantities, special cartons, bubble bags, rubber pads, trays, wooden boxes, etc. can be customized for large quantities, and the corresponding finished or semi-finished product labels will be pasted on the carton after the packaging is completed.

The company has established a sound quality control system, from raw material procurement to final delivery of products, each link is strictly controlled. In the raw material procurement stage, suppliers are strictly screened and evaluated to ensure that the purchased raw materials such as sheet metal meet quality standards.

In the production process, a number of quality inspection points are set up to detect the products in each process in real time. For example, after the shearing, punching, bending and other processes of sheet metal processing, as well as the completion of each link of the stamping process, the dimensional accuracy and surface quality of the workpiece should be tested, and the process parameters should be adjusted or reworked in time once the problem is found.

Send Inquiry

You may like