OEM Trailer Coupler and Hitch Components: Key Features and Benefits

2026-01-02 15:51:11

Every trailer owner faces a critical moment: will your coupler hold when you're hauling a heavy load down the highway, or will a weak connection lead to disaster? The difference between a safe journey and a catastrophic failure often comes down to choosing the right OEM Trailer Coupler and Hitch Components. These precision-engineered connection systems aren't just metal parts—they're the lifeline between your towing vehicle and valuable cargo. Understanding what makes quality OEM Trailer Coupler and Hitch Components essential can save you from costly accidents, equipment damage, and safety hazards that compromise every trip you take.

Understanding OEM Trailer Coupler and Hitch Components

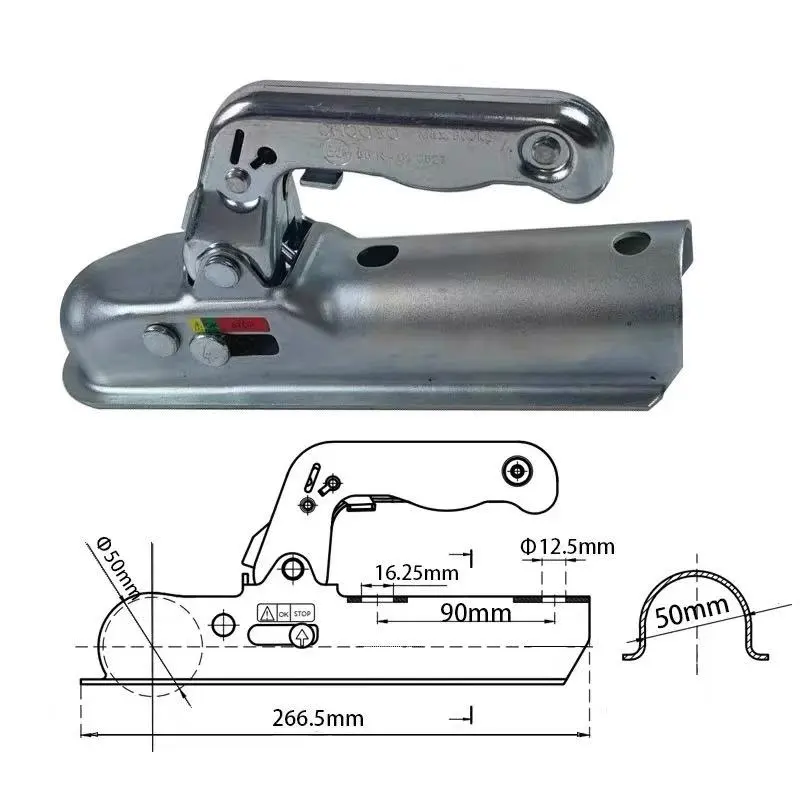

OEM Trailer Coupler and Hitch Components represent the critical connection point in any towing system, serving as the mechanical link that secures your trailer to the towing vehicle. These components are manufactured to original equipment specifications, ensuring precise engineering, consistent quality, and reliable performance across various towing applications. The term "OEM" signifies that these parts meet the exact standards set by equipment manufacturers, providing superior fitment and durability compared to aftermarket alternatives. The fundamental structure of OEM Trailer Coupler and Hitch Components includes several essential elements working in concert. The coupler body forms the main housing that connects directly to the trailer tongue, while the latching mechanism ensures the coupler stays securely attached to the hitch ball during operation. Additional components such as the hinge pin allow the latch to move for attachment and release, while the adjustment nut enables fine-tuning for a snug fit around the trailer ball. Safety pins secure the latch to prevent accidental disengagement during towing operations, creating multiple layers of protection. Manufacturing quality separates premium OEM Trailer Coupler and Hitch Components from inferior products. High-grade materials such as forged steel, cast steel, and specialized aluminum alloys undergo rigorous testing to ensure they can withstand the extreme stresses of heavy-duty towing. Advanced production techniques including progressive stamping, deep drawing, and precision CNC machining create components with consistent dimensional accuracy and structural integrity. Surface treatments such as powder coating, zinc plating, and specialized corrosion-resistant finishes protect against environmental degradation, extending service life significantly in harsh operating conditions.

Weight Capacity and Load Distribution

Weight capacity stands as the most critical specification when selecting OEM Trailer Coupler and Hitch Components for any towing application. These components are rated for gross trailer weight, which represents the total weight of the fully loaded trailer including the trailer itself, cargo, fuel, water, and any additional equipment. Matching coupler capacity to actual towing requirements ensures structural integrity under load and prevents catastrophic failure during transport. Tongue weight, typically ranging from ten to fifteen percent of total trailer weight, creates downward force on the hitch ball that must be properly supported by the coupler system. OEM Trailer Coupler and Hitch Components designed for specific weight classes feature reinforced construction, larger bearing surfaces, and enhanced latching mechanisms that distribute loads evenly across the connection point. This engineered approach to weight management reduces stress concentrations, minimizes metal fatigue, and extends component service life even under demanding operating conditions. Proper load distribution through quality OEM Trailer Coupler and Hitch Components affects vehicle handling, braking performance, and overall towing safety. Incorrect weight balance can cause trailer sway, reduced steering control, and excessive wear on towing vehicle suspension components. Premium couplers incorporate design features that maintain optimal weight distribution throughout the full range of towing conditions, from highway speeds to tight maneuvering in confined spaces, ensuring consistent performance regardless of operating environment.

Material Selection and Manufacturing Processes

Material science plays a fundamental role in OEM Trailer Coupler and Hitch Components performance and longevity. Mild steel offers excellent formability and weldability for general-purpose applications, while cold rolled steel provides superior surface finish and dimensional accuracy for precision components. Stainless steel delivers exceptional corrosion resistance in marine environments or regions with heavy salt exposure. Aluminum alloys reduce weight without sacrificing strength in applications where payload capacity is critical. Each material selection reflects specific engineering requirements and operational demands. Advanced manufacturing processes transform raw materials into precision OEM Trailer Coupler and Hitch Components. Progressive stamping operations produce complex shapes in multiple stages, maintaining tight tolerances while achieving high production efficiency. Deep drawing techniques create cup-shaped components that form the ball receiver, ensuring consistent geometry and proper hitch ball engagement. CNC machining adds precision features such as threaded holes, mounting surfaces, and adjustment mechanisms that require exact dimensional control for proper assembly and operation. Secondary finishing operations enhance both function and appearance of OEM Trailer Coupler and Hitch Components. Deburring removes sharp edges that could cause injury during installation or maintenance. Polishing creates smooth surfaces that reduce friction and wear in moving parts. Powder coating provides durable, impact-resistant finishes in various colors for brand identification and aesthetic appeal. Electroplating applies protective metal layers that resist corrosion and extend service life in challenging environments. These finishing processes represent the final quality steps that differentiate premium components from basic alternatives.

Types of OEM Trailer Coupler and Hitch Components

Ball couplers represent the most widely used category of OEM Trailer Coupler and Hitch Components, suitable for light to medium-duty towing applications. These couplers feature a socket that clamps over a spherical hitch ball, creating a secure connection while allowing necessary articulation during turns and over uneven terrain. Available in standard sizes including one and seven-eighths inch, two inch, and two and five-sixteenths inch configurations, ball couplers accommodate various trailer weights from small utility trailers to substantial recreational vehicles. The latching mechanism varies by design, with options including lever-style latches, screw-type adjusters, and quick-release systems that balance security with user convenience. A-frame couplers serve trailers with V-shaped tongue configurations, offering enhanced stability and load capacity compared to straight-tongue designs. These OEM Trailer Coupler and Hitch Components mount to the converging frame members of the A-frame structure, distributing forces across a wider base for improved strength. Manufacturing typically involves heavy-duty stamped steel or cast construction, with mounting patterns designed to match industry-standard frame angles. A-frame couplers handle heavier loads while maintaining compact dimensions, making them ideal for enclosed trailers, equipment haulers, and mid-sized recreational trailers where stability and reliability are paramount.

Channel Mount and Adjustable Systems

Channel mount couplers, also classified as straight-tongue designs, attach to rectangular tube trailer tongues through bolted connections or welded installation. These OEM Trailer Coupler and Hitch Components slide over the square tubular frame, providing secure mounting without frame modification requirements in many cases. The channel design allows for easy replacement when wear occurs, as the coupler can be removed and replaced without cutting or welding operations. Weight capacities range from light-duty applications up to substantial loads, with appropriate models available for various towing requirements. Adjustable coupler systems provide versatility for operators who tow with multiple vehicles or need height adjustment capability. These OEM Trailer Coupler and Hitch Components feature mechanisms that allow vertical positioning changes, accommodating different vehicle heights without trailer modification. Some advanced designs incorporate tool-free adjustment systems that enable quick changes in the field, particularly valuable for rental fleets and commercial operators serving diverse customer bases. The adjustment mechanism maintains structural integrity across the full range of positions, ensuring safety regardless of the selected height setting. Specialized channel mount designs accommodate unique trailer configurations including those requiring surge brake actuators for hydraulic braking systems. These integrated OEM Trailer Coupler and Hitch Components combine the coupling function with brake activation, synchronizing trailer braking with tow vehicle deceleration through a hydraulic cylinder mechanism. This dual-purpose design simplifies trailer construction while ensuring coordinated braking performance, particularly important for boat trailers and other applications where supplemental braking is required for safe operation.

Heavy-Duty and Specialized Configurations

Gooseneck couplers represent the heavy-duty category of OEM Trailer Coupler and Hitch Components, designed for substantial loads including livestock trailers, large equipment haulers, and commercial applications. These couplers mount above the rear axle of the tow vehicle, utilizing a vertical coupler shaft that connects to a ball mounted in the truck bed. Weight capacities extend from fifteen thousand pounds to thirty thousand pounds or more, with the elevated mounting position providing superior weight distribution and enhanced maneuverability compared to conventional hitch systems. The design allows tighter turning radius while maintaining stability under heavy loads. Fifth wheel couplers employ a kingpin connection system similar to semi-trailer designs, offering exceptional stability for large recreational vehicles and heavy trailers. These OEM Trailer Coupler and Hitch Components feature a locking jaw mechanism that engages a kingpin extending downward from the trailer, creating a secure connection that distributes weight over a large bearing surface. The elevated pivot point above the rear axle improves handling characteristics and reduces sway compared to conventional bumper-mounted hitches. Installation requires a substantial fifth wheel hitch mounted in the towing vehicle bed, representing a significant investment justified by superior towing performance. Pintle ring couplers provide maximum durability for extreme-duty applications including military, construction, and agricultural equipment. These OEM Trailer Coupler and Hitch Components utilize a lunette ring on the trailer that engages with a pintle hook mounted on the tow vehicle, creating a connection that tolerates significant articulation and misalignment. The design excels in off-road conditions and rough terrain where conventional ball couplers would bind or fail. Weight capacities reach thirty-six thousand pounds in premium configurations, with the robust construction withstanding impacts and abuse that would destroy lesser connection systems.

Key Features of Quality OEM Trailer Coupler and Hitch Components

Latching mechanisms represent the critical safety feature in OEM Trailer Coupler and Hitch Components, determining how securely the coupler engages with the hitch ball and preventing accidental separation during operation. Lever-style latches provide quick engagement with visual confirmation of proper locking, while screw-type mechanisms offer adjustable clamping force that compensates for wear over time. Advanced designs incorporate positive locking features including safety catches, secondary retention devices, and anti-rattle mechanisms that eliminate slack in the connection. The latching system must operate reliably across temperature extremes, resist corrosion, and maintain consistent performance throughout the component service life. Corrosion resistance extends OEM Trailer Coupler and Hitch Components service life, particularly in marine environments, winter climates with road salt exposure, and industrial settings with chemical contamination. Premium couplers receive multiple protective treatments including zinc plating for sacrificial corrosion protection, powder coating for impact and abrasion resistance, and specialized sealants that prevent moisture intrusion into critical areas. Stainless steel construction eliminates rust concerns entirely in applications justifying the higher material cost. Regular inspection and maintenance of protective finishes ensures long-term durability even in harsh operating conditions.

Safety Features and Compliance Standards

Safety chains and emergency breakaway systems complement OEM Trailer Coupler and Hitch Components, providing backup connection in the event of coupler failure or hitch ball separation. Mounting provisions integrated into coupler designs ensure proper chain attachment points that maintain strength under emergency loads. Chain length and crossing pattern under the tongue create a catch system that prevents the trailer tongue from contacting the ground if primary connection fails, allowing controlled stopping rather than catastrophic loss of control. Industry compliance standards govern OEM Trailer Coupler and Hitch Components design, testing, and certification processes. ISO quality management systems ensure consistent manufacturing processes and dimensional accuracy across production runs. Products meeting SAE and ASTM specifications demonstrate verified performance under standardized testing protocols including static load testing, dynamic fatigue testing, and corrosion resistance evaluation. Certification markings stamped or cast into coupler bodies provide verification of compliance, offering assurance that components meet minimum performance requirements for their rated capacity. Quality assurance processes at manufacturing facilities verify each production batch of OEM Trailer Coupler and Hitch Components meets established standards. Dimensional inspection confirms proper fitment with standard hitch balls and mounting configurations. Material testing verifies alloy composition and heat treatment effectiveness. Load testing of sample units from each production run validates structural integrity under rated loads with appropriate safety factors. Documentation systems track manufacturing processes, enabling traceability from raw material receipt through final shipping, supporting warranty claims and continuous improvement initiatives.

Installation and Maintenance Considerations

Proper installation of OEM Trailer Coupler and Hitch Components ensures optimal performance and safety throughout component service life. Bolt-on couplers require torque specifications be followed precisely, with thread locking compounds applied to prevent loosening from vibration. Welded installations demand qualified welding procedures, appropriate filler materials, and complete penetration welds that develop full strength of base materials. Incorrect installation procedures create weak points that can fail under load, potentially causing accidents and equipment damage far exceeding the cost of proper installation practices. Maintenance requirements for OEM Trailer Coupler and Hitch Components include regular inspection of wear surfaces, latching mechanisms, and mounting hardware. The ball socket interior should be checked for cracks, excessive wear, or corrosion that could compromise grip on the hitch ball. Latch components need periodic lubrication with appropriate grease that resists washout and maintains function across operating temperature ranges. Adjustment mechanisms require periodic check and reset to maintain proper clamping force as normal wear occurs. Documentation of maintenance activities supports warranty claims and demonstrates due diligence in equipment care. Replacement intervals for OEM Trailer Coupler and Hitch Components depend on usage intensity, operating conditions, and inspection findings. Components showing cracks, significant corrosion, or excessive wear in critical areas require immediate replacement rather than continued service. Even without visible damage, couplers used in heavy-duty commercial applications benefit from scheduled replacement based on operating hours or mileage to prevent unexpected failures. Maintaining spare couplers appropriate for trailer fleet requirements ensures minimal downtime when replacement becomes necessary, supporting operational continuity and preventing schedule disruptions.

Benefits of Choosing OEM Trailer Coupler and Hitch Components

Engineering precision distinguishes OEM Trailer Coupler and Hitch Components from generic aftermarket alternatives, ensuring proper dimensional accuracy for secure fitment with standard hitch systems. Original equipment specifications reflect extensive testing and validation processes that optimize component geometry for maximum strength-to-weight ratios. Precise manufacturing tolerances ensure consistent ball engagement, proper latch operation, and reliable performance across the full rated capacity range. This engineering investment results in components that install correctly, operate smoothly, and deliver predictable service life under normal operating conditions. Material quality in OEM Trailer Coupler and Hitch Components provides superior performance and longevity compared to economy alternatives manufactured to minimum cost targets. Premium steel alloys offer higher yield strength, better fatigue resistance, and improved weldability for applications requiring frame modifications. Advanced heat treatment processes optimize material properties for specific loading conditions, balancing hardness for wear resistance with toughness to prevent brittle fracture. Quality materials justify higher initial costs through extended service intervals, reduced maintenance requirements, and lower total cost of ownership across component lifecycle.

Long-Term Reliability and Performance

Structural integrity testing verifies OEM Trailer Coupler and Hitch Components exceed their rated capacity with appropriate safety margins, providing confidence under demanding operating conditions. Static load testing applies forces exceeding maximum rated capacity to verify the component withstands overload situations without permanent deformation or fracture. Dynamic fatigue testing cycles components through repeated loading and unloading, simulating years of service to identify potential failure modes before products reach customers. Impact testing validates component response to sudden shock loads encountered in emergency braking or rough terrain operation. Warranty support accompanying OEM Trailer Coupler and Hitch Components demonstrates manufacturer confidence in product quality and performance. Comprehensive warranty coverage protects against manufacturing defects, material failures, and premature wear under normal operating conditions. Responsive technical support assists with application questions, installation guidance, and troubleshooting when issues arise. Replacement parts availability ensures components can be maintained and repaired rather than requiring complete assembly replacement, reducing long-term operating costs and supporting sustainability objectives through extended product life. Consistency across production batches ensures OEM Trailer Coupler and Hitch Components purchased years apart maintain identical specifications and interchangeability. Documented manufacturing processes, controlled material sources, and validated inspection procedures prevent variation that could compromise fitment or performance. Fleet operators particularly value this consistency when maintaining diverse equipment populations, as standardization on specific OEM components simplifies spare parts inventory, technician training, and maintenance procedures across multiple facilities and operational regions.

Cost-Effectiveness and Value Proposition

Initial investment in quality OEM Trailer Coupler and Hitch Components appears higher than budget alternatives, yet delivers superior value through reduced maintenance costs, extended service life, and avoided downtime expenses. Premium components resist wear and corrosion more effectively, requiring less frequent replacement and reducing total parts expenditure over equipment lifecycle. Reliable operation prevents unexpected failures that cause costly service interruptions, delayed deliveries, and potential cargo damage. Safety performance reduces accident risk and associated liability exposures, protecting both personnel and financial assets. Operational efficiency improves with properly engineered OEM Trailer Coupler and Hitch Components that maintain secure connections without excessive weight or complexity. Optimized weight distribution enhances vehicle handling and braking performance, improving fuel economy and reducing tire wear on both towing vehicle and trailer. Reduced maintenance requirements free technician time for other value-adding activities rather than repeated coupler adjustments and repairs. Simplified installation procedures for bolt-on designs minimize labor costs when replacement becomes necessary, further enhancing overall cost-effectiveness. Risk mitigation represents substantial hidden value in OEM Trailer Coupler and Hitch Components selection decisions. Component failure during highway operation creates severe accident potential with resulting injury risks, equipment damage, cargo loss, and legal liability. Quality couplers manufactured to recognized standards and properly rated for application provide documented evidence of reasonable care in equipment selection, supporting legal defense if incidents occur despite proper practices. Insurance considerations may favor equipment specified with certified components, potentially reducing premium costs while ensuring adequate coverage for operational exposures.

Conclusion

OEM Trailer Coupler and Hitch Components represent critical investments in towing safety, operational reliability, and long-term cost-effectiveness. Quality engineering, precision manufacturing, and rigorous testing deliver components that perform consistently under demanding conditions while providing the durability necessary for extended service life. Selecting appropriate couplers based on application requirements, load capacities, and operating environments ensures optimal performance and minimizes risk exposures.

Cooperate With Qingdao RUIRUI Machinary Co., LTD.

As a leading China OEM Trailer Coupler and Hitch Components factory, Qingdao RUIRUI Machinery Co., LTD. specializes in manufacturing precision-engineered towing components that exceed industry standards. Our China OEM Trailer Coupler and Hitch Components supplier capabilities encompass complete design, production, and quality assurance services backed by ISO 9001, ISO 14001, and OHSAS 18001 certifications. As an experienced China OEM Trailer Coupler and Hitch Components manufacturer, we utilize advanced stamping, laser cutting, CNC machining, and robotic welding technologies to produce components meeting exact specifications across our eight production lines with 130,000-piece annual capacity.

Our China OEM Trailer Coupler and Hitch Components wholesale programs serve distributors, equipment manufacturers, and fleet operators worldwide, with products exported to over eighty countries including North America, Europe, and Australia. We offer competitive OEM Trailer Coupler and Hitch Components for sale with customization services supporting unique application requirements, specialized materials including mild steel, stainless steel, aluminum alloys, and brass, plus comprehensive surface finishing options. Our competitive OEM Trailer Coupler and Hitch Components price structure reflects efficient production processes without compromising the High Quality OEM Trailer Coupler and Hitch Components our customers demand.

Partner with RUIRUI Machinery to access technical expertise, OEM support, short delivery times, and professional packaging ensuring your components arrive ready for immediate installation. Our experienced engineering team provides comprehensive technical support throughout the product development process, from initial concept through production optimization. Contact us today at info@qdkshd.com to discuss your specific requirements and discover how our manufacturing capabilities can enhance your towing equipment performance and reliability.

References

1. Society of Automotive Engineers. "Trailer Couplings - Automotive Type - Performance Requirements." SAE Standard J684. Society of Automotive Engineers International.

2. American Society for Testing and Materials. "Standard Specification for Trailer Couplers and Fifth-Wheel Connection Assemblies." ASTM F1331. ASTM International.

3. National Highway Traffic Safety Administration. "Federal Motor Vehicle Safety Standards - Trailer Brake Systems." FMVSS No. 121. U.S. Department of Transportation.

4. International Organization for Standardization. "Road Vehicles - 50 mm Spherical and 50 mm Towing Coupler - Part 1: Basic Requirements and Vehicle-Related Test Methods." ISO 7636-1. International Organization for Standardization.

5. Trailer Manufacturers Association. "Equipment and Maintenance Guidelines for Trailer Couplers and Hitches." TMA Technical Bulletin Series. Recreational Vehicle Industry Association.

Send Inquiry

You may like