OEM Wholesale Price Trailer Hitch Lock Pins: Supplier Guide

2025-12-17 10:57:01

Picture this scenario: you've just invested thousands of dollars in your commercial trailer fleet, only to find one morning that your expensive ball mounts have disappeared overnight, or worse, an entire trailer has been stolen from your facility. This nightmare situation costs businesses millions annually, yet it's entirely preventable with the right security solution. Finding reliable OEM Wholesale Price Trailer Hitch Lock Pins from a trustworthy supplier can mean the difference between losing valuable assets and maintaining uninterrupted operations. This comprehensive guide will walk you through everything you need to know about sourcing high-quality Trailer Hitch Lock Pins at competitive wholesale prices, helping you make informed decisions that protect your investment while maximizing cost efficiency for your business operations.

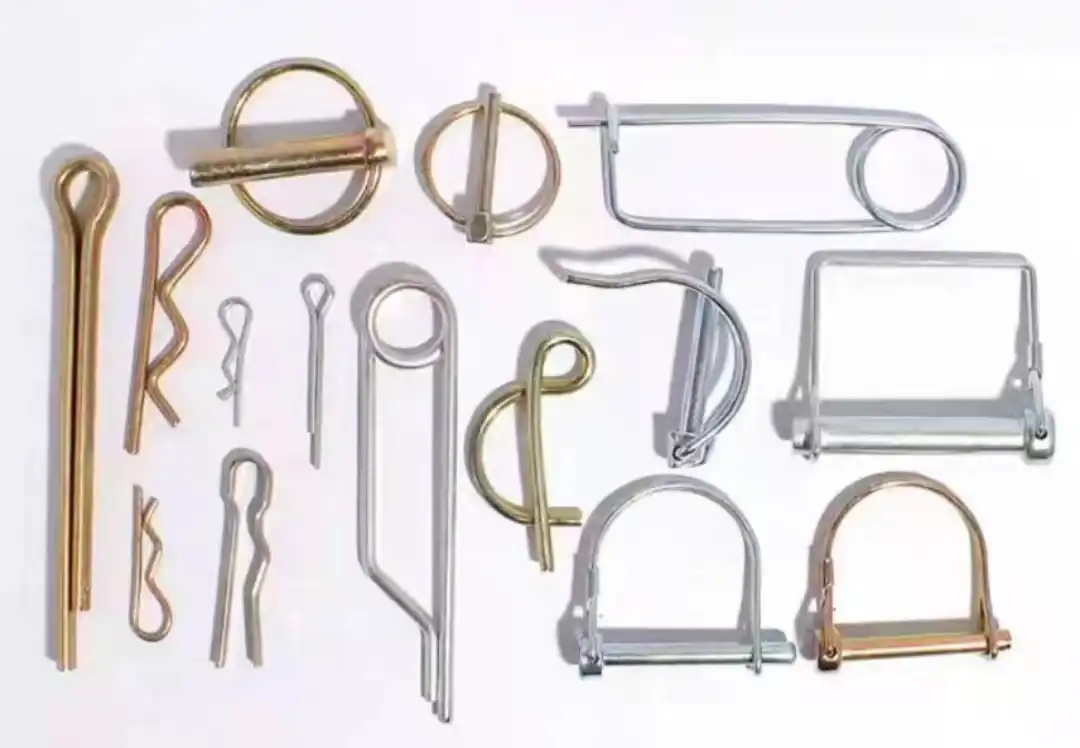

Understanding Trailer Hitch Lock Pins and Their Critical Role in Security

Trailer Hitch Lock Pins serve as the primary security mechanism that connects your ball mount to the receiver hitch while simultaneously preventing theft of both the towing accessories and the trailer itself. Unlike standard hitch pins that rely solely on simple clip mechanisms, Trailer Hitch Lock Pins integrate a keyed locking system that creates a formidable barrier against unauthorized removal. These specialized security components typically feature a notched shank that engages with a cylinder lock mechanism, similar to how a padlock operates, but specifically engineered to withstand the unique stresses and environmental conditions encountered in towing applications. The importance of Wholesale Price Trailer Hitch Lock Pins extends far beyond simple theft prevention. In commercial operations where multiple trailers and towing vehicles are in constant use, the cost savings achieved through wholesale purchasing can significantly impact your bottom line while ensuring consistent security standards across your entire fleet. Quality Trailer Hitch Lock Pins are manufactured from high-grade materials such as hardened steel, stainless steel, or chrome-plated alloys that resist corrosion, drilling, cutting, and picking attempts. The pin diameter must match your receiver class specifications precisely, with common sizes ranging from half-inch diameter for Class I and II receivers up to three-quarter-inch diameter for heavy-duty Class IV and V applications that handle loads exceeding twenty thousand pounds.

Material Selection and Manufacturing Standards for Durability

When sourcing Trailer Hitch Lock Pins from OEM manufacturers, material composition becomes paramount to long-term performance and reliability. Premium manufacturers utilize cold-rolled steel or stainless steel construction that undergoes specific heat treatment processes to achieve optimal hardness ratings between forty-five and fifty-five on the Rockwell C scale. This hardness level ensures the pin can withstand attempted breaching while maintaining enough ductility to avoid brittle fracture under dynamic loading conditions during transport. Surface treatments including powder coating, zinc plating, chrome plating, or anodizing provide additional protection against environmental degradation from road salt, moisture, and ultraviolet exposure. Advanced manufacturing facilities employ progressive stamping and CNC machining technologies to maintain extremely tight tolerances on critical dimensions such as pin diameter, shank length, and locking mechanism engagement surfaces. The precision achieved through these processes ensures smooth operation of the locking cylinder while preventing binding or jamming that could leave users locked out or unable to secure their equipment properly. Quality control protocols at reputable OEM facilities include destructive testing of sample batches to verify tensile strength, shear resistance, and lock cylinder durability under simulated real-world conditions. Documentation of these test results and material certifications should be readily available from any serious wholesale supplier you consider for your sourcing needs.

Key Factors in Evaluating Wholesale Suppliers

Selecting the right supplier for your Wholesale Price Trailer Hitch Lock Pins requires careful evaluation of multiple critical factors beyond simple unit pricing. Production capacity represents a fundamental consideration, particularly for businesses requiring consistent large-volume supply to support ongoing operations or seasonal demand fluctuations. A capable manufacturer should operate multiple production lines with annual output measured in hundreds of thousands of units, ensuring they can scale to meet your requirements without compromising delivery schedules or quality standards. Automated manufacturing processes including robotic welding, automated surface treatment lines, and computerized quality inspection systems indicate a supplier's commitment to consistency and efficiency. Certification credentials provide objective validation of a manufacturer's operational excellence and commitment to international standards. Look for suppliers holding ISO 9001 quality management certification, which demonstrates systematic processes for maintaining product consistency and continuous improvement. Environmental certifications such as ISO 14001 show responsible manufacturing practices, while occupational health and safety certifications like OHSAS 18001 indicate proper worker protection and training programs. These certifications aren't merely bureaucratic formalities but represent genuine operational frameworks that directly impact product quality, delivery reliability, and long-term supplier stability. Additionally, inquire about intellectual property portfolio including utility patents and design patents, which suggest innovation capability and investment in product development rather than simply copying existing designs.

Customization Options and OEM Capabilities for Specialized Applications

One significant advantage of working directly with OEM manufacturers for your Trailer Hitch Lock Pins needs is access to extensive customization capabilities that standard off-the-shelf products cannot provide. Professional manufacturers with comprehensive metal fabrication facilities offer modification services including custom pin lengths to accommodate non-standard receiver depths, specialized finishes for extreme environment applications, and proprietary locking mechanisms keyed to your existing fleet key systems. This keyed-alike capability proves particularly valuable for commercial operations managing dozens or hundreds of trailers, eliminating the logistical nightmare of tracking unique keys for each individual lock while maintaining security integrity across the entire fleet. Advanced OEM partners can engineer Trailer Hitch Lock Pins for specialized weight ratings exceeding standard classifications, incorporating features such as anti-rattle threading mechanisms, integrated dust caps with lanyard attachment points, and corrosion-resistant materials suitable for marine environments or chemical exposure. The design process typically begins with detailed specification discussions where your technical team collaborates with the manufacturer's engineering department to define exact requirements including dimensional constraints, load ratings, environmental exposure parameters, and aesthetic preferences. Prototyping capabilities allow testing and validation before committing to full production runs, ensuring the final product meets all performance criteria while maintaining cost-effectiveness at wholesale price points.

Technical Support and Engineering Assistance Throughout the Procurement Process

Reputable suppliers of Wholesale Price Trailer Hitch Lock Pins distinguish themselves through comprehensive technical support services that extend far beyond simple order fulfillment. Engineering teams should be readily accessible to discuss application-specific requirements, recommend appropriate specifications for your particular use cases, and provide detailed technical documentation including CAD drawings, material certifications, and performance test results. This consultative approach helps buyers avoid costly specification errors that could result in incompatible products, premature failures, or safety concerns in actual field deployment. Throughout the procurement lifecycle, professional OEM manufacturers maintain detailed communication regarding production schedules, quality control checkpoints, and shipment coordination. They understand that businesses relying on these critical safety components need predictable supply chains and proactive notification of any potential delays or issues that could impact operations. Technical support extends into the post-purchase period with assistance on proper installation procedures, maintenance recommendations to maximize service life, and troubleshooting guidance should any performance issues arise. This ongoing relationship builds the foundation for continuous improvement, allowing the supplier to gather field feedback that informs future product enhancements and ensures their offerings evolve to meet changing market demands.

Quality Assurance Protocols and Testing Standards

Quality assurance represents the cornerstone of reliable Trailer Hitch Lock Pins manufacturing, separating professional OEM suppliers from questionable low-cost alternatives that may compromise safety and durability. Comprehensive quality management systems begin with incoming material inspection, where raw materials undergo verification testing to confirm they meet specified composition, hardness, and dimensional requirements before entering the production process. Statistical process control methods monitor critical manufacturing parameters in real-time, identifying and correcting variations before they result in defective products reaching customers. Finished product inspection protocols should include both non-destructive and destructive testing methodologies. Non-destructive techniques such as dimensional verification using calibrated measurement equipment, visual inspection for surface defects, and functional testing of locking mechanisms ensure every unit meets specifications. Destructive testing of representative samples validates critical performance characteristics including tensile strength, shear resistance, lock cylinder durability through thousands of operation cycles, and corrosion resistance through salt spray exposure testing. Documentation systems track every production batch with detailed records creating full traceability should any field issues require investigation and corrective action.

Compliance with International Standards and Safety Regulations

Professional manufacturers of Trailer Hitch Lock Pins maintain rigorous compliance with relevant international standards and safety regulations governing towing equipment. In North America, products should meet SAE (Society of Automotive Engineers) standards for towing components, while European markets require conformity with relevant EN standards. These specifications define minimum performance requirements for strength, durability, corrosion resistance, and operational safety that products must demonstrate through certified testing procedures. Suppliers should readily provide documentation of compliance testing performed by accredited third-party laboratories rather than relying solely on internal testing claims. Beyond product-specific standards, facility-level certifications indicate systematic approaches to quality and safety management. ISO 9001 certification requires documented quality management systems with defined processes for design control, production management, inspection procedures, and continuous improvement. Environmental management systems certified to ISO 14001 demonstrate responsible handling of materials, waste management, and pollution prevention. Occupational health and safety certifications ensure proper worker protection, training programs, and accident prevention measures. These certifications undergo regular third-party audits to maintain validity, providing buyers with confidence that the supplier operates with professional standards and systematic controls rather than ad-hoc practices that could result in quality variations or supply disruptions.

Pricing Structures and Cost Optimization Strategies

Understanding pricing structures for Wholesale Price Trailer Hitch Lock Pins enables buyers to optimize procurement costs while ensuring quality standards remain uncompromised. Volume-based pricing tiers typically offer significant per-unit cost reductions as order quantities increase, with breakpoints often occurring at quantities of one thousand, five thousand, and ten thousand units or more. However, buyers must balance volume discount benefits against inventory carrying costs, capital requirements, and the risks of specification obsolescence if product designs evolve. Strategic buyers often negotiate annual purchase agreements that commit to minimum total volumes while allowing flexible delivery scheduling in smaller batches, capturing volume pricing benefits without excessive inventory investments. Customization requirements naturally impact pricing, with standard catalog products offering the lowest per-unit costs while custom specifications incur engineering, tooling, and setup expenses that must be amortized across the production run. For buyers requiring specialized Trailer Hitch Lock Pins, working with OEM manufacturers who maintain diverse production capabilities including progressive stamping, CNC machining, laser cutting, and various surface treatment options provides cost advantages through process optimization and reduced outsourcing requirements. Discussing your specific needs early in the procurement process allows manufacturers to recommend design modifications that maintain functionality while leveraging existing tooling or standard components, reducing custom costs without compromising performance.

Total Cost of Ownership Beyond Initial Purchase Price

Sophisticated procurement professionals evaluate Trailer Hitch Lock Pins suppliers based on total cost of ownership rather than focusing exclusively on initial purchase price. Product reliability directly impacts ongoing costs, as premature failures necessitate replacement purchases, labor for changeovers, and potential downtime losses if equipment becomes unusable due to failed security components. Higher-quality products from established OEM manufacturers typically command modest price premiums but deliver substantially longer service lives and reduced failure rates that more than offset the initial cost difference over the product lifecycle. Supply chain reliability represents another critical cost factor often overlooked in simple price comparisons. Suppliers with robust production capacity, proper inventory management, and proven logistics capabilities ensure consistent product availability when you need it, avoiding costly emergency orders, expedited shipping charges, or operational disruptions due to stockouts. Professional suppliers invest in systems and processes that provide order status visibility, proactive communication about potential delays, and contingency planning to address supply chain disruptions. The value of this reliability becomes particularly evident during peak seasons or unexpected demand surges when less capable suppliers may fail to deliver, forcing buyers into expensive spot purchases from alternative sources at inflated pricing.

Conclusion

Sourcing quality OEM Wholesale Price Trailer Hitch Lock Pins requires evaluating suppliers across multiple critical dimensions including manufacturing capabilities, quality assurance protocols, customization options, technical support services, and total cost of ownership considerations. By partnering with established manufacturers offering comprehensive metal fabrication expertise, certified quality management systems, and proven supply chain reliability, businesses can secure their valuable towing assets while optimizing procurement costs through strategic volume purchasing and long-term supplier relationships.

Cooperate With Qingdao RUIRUI Machinary Co., LTD.

As a leading China Trailer Hitch Lock Pins manufacturer and China Trailer Hitch Lock Pins supplier established in 2016, Qingdao RUIRUI Machinery Co., LTD specializes in producing high-quality trailer accessories including Trailer Hitch Lock Pins through advanced manufacturing processes. Our China Trailer Hitch Lock Pins factory operates eight production lines with fully automated robotic systems and thermoplastic coating processes, generating annual output of 130,000 pieces while maintaining competitive Trailer Hitch Lock Pins prices. We offer High Quality Trailer Hitch Lock Pins manufactured from premium materials including mild steel, stainless steel, aluminum alloys, and brass, processed through progressive stamping, CNC machining, laser cutting, and finished with powder coating, plating, anodizing, or electrophoresis according to your specifications.

Our China Trailer Hitch Lock Pins wholesale operations are backed by ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001 certifications, ensuring systematic quality control throughout production. With over fifteen years of management experience and numerous utility model patents, we provide comprehensive OEM support for custom Trailer Hitch Lock Pins for sale tailored to your exact requirements. Our technical support team offers engineering assistance, after-sales service, and professional packaging ensuring secure transportation to more than eighty countries worldwide. Whether you need standard products or customized solutions, our efficient production processes guarantee short delivery times without compromising quality.

Ready to secure your fleet with reliable Trailer Hitch Lock Pins at competitive wholesale prices? Contact our team today at info@qdkshd.com to discuss your specific requirements, request detailed specifications, or place your order. Bookmark this guide for easy reference whenever you need expert information about trailer security solutions, and reach out with any questions about how our manufacturing capabilities can support your business needs.

References

1. "Trailer Coupling and Hitch Safety Standards: A Comprehensive Guide for Fleet Managers" - Society of Automotive Engineers (SAE) International, Technical Standards Committee

2. "Metal Fabrication Processes in Transportation Components Manufacturing" - American Society of Metals (ASM) International, Manufacturing Technology Division

3. "Quality Management Systems in Automotive Parts Production: ISO 9001 Implementation" - International Organization for Standardization (ISO), Quality Management Standards Board

4. "Corrosion Protection Methods for Steel Towing Components" - National Association of Corrosion Engineers (NACE) International, Materials Performance Research Institute

5. "Security Hardware Design and Testing Protocols for Commercial Vehicle Applications" - Automotive Industry Action Group (AIAG), Product Quality Standards Working Group

Send Inquiry

You may like