Solve Multiple Towing Needs with One Adjustable Trailer Coupler

2025-09-30 11:23:26

Picture this scenario: you're a fleet manager responsible for transporting different types of trailers daily, from construction equipment haulers to cargo trailers of varying heights. The constant struggle of mismatched ball heights and incompatible coupling systems wastes precious time and creates safety hazards. The adjustable trailer coupler eliminates these challenges by providing a tight and secure fit while accommodating multiple towing configurations. An adjustable trailer coupler represents the ultimate solution for modern towing challenges, offering versatility that transforms complex multi-vehicle operations into streamlined processes. This comprehensive guide reveals how one innovative component can revolutionize your entire towing strategy.

Understanding Adjustable Trailer Coupler Technology

Modern adjustable trailer coupler systems have evolved far beyond simple mechanical connections to become sophisticated engineering solutions that address multiple operational challenges simultaneously. These advanced coupling mechanisms incorporate precision-engineered adjustment systems that accommodate various ball sizes and heights while maintaining optimal towing alignment across different vehicle combinations. The core technology behind today's adjustable trailer coupler designs focuses on providing seamless height adjustment capabilities that eliminate the need for multiple specialized couplers in fleet operations. Professional-grade adjustable trailer couplers feature robust construction using high-grade steel with corrosion-resistant coatings, ensuring long-lasting performance in demanding applications. These couplers promote level towing by incorporating sophisticated adjustment mechanisms that compensate for height differences between tow vehicles and trailers. The engineering principles underlying these systems prioritize both safety and efficiency, with trigger-style latching mechanisms that provide secure connections while enabling quick coupling and uncoupling operations.

-

Engineering Excellence in Design

The sophisticated design philosophy behind modern adjustable trailer couplers incorporates multiple engineering disciplines to create solutions that exceed traditional coupling limitations. Advanced metallurgy techniques ensure that each 2 5/16" Ball Adjustable Height coupler can withstand extreme stress loads while maintaining precise adjustment capabilities throughout its operational lifespan. The integration of thermoplastic coating processes provides additional protection against environmental factors that typically compromise traditional coupling systems. Manufacturing precision becomes critical when producing adjustable trailer couplers that must accommodate the demanding requirements of professional towing applications. Each 2" adjustable trailer coupler undergoes rigorous quality control processes that verify dimensional accuracy, load capacity specifications, and adjustment mechanism reliability. The result is a coupling system that delivers consistent performance across diverse towing scenarios while maintaining the flexibility needed for multi-application use.

The Versatility Advantage of Multi-Application Couplers

The revolutionary aspect of modern adjustable trailer coupler technology lies in its ability to eliminate the complexity traditionally associated with managing diverse towing requirements. Fleet operators who previously maintained extensive inventories of specialized couplers for different applications now discover that a single high-quality adjustable trailer coupler can handle multiple towing scenarios effectively. This versatility extends beyond simple height adjustments to encompass compatibility with various ball sizes and trailer tongue configurations. The versatile heavy-duty trailer coupler is compatible with a wide range of vehicle types, including sedans, SUVs, and trucks, demonstrating the broad applicability that makes these systems invaluable for professional operations. The ability to maintain stable towing performance across different vehicle combinations eliminates compatibility issues that historically required specialized equipment purchases. This comprehensive compatibility ensures that operators can maximize their equipment investments while minimizing operational complexity.

-

Operational Efficiency Through Standardization

The standardization benefits achieved through adjustable trailer coupler implementation create significant operational advantages that extend throughout entire fleet management systems. When maintenance teams can rely on standardized coupling systems across diverse trailer applications, training requirements become simplified while parts inventory management becomes more efficient. The 2 5/16" Ball Adjustable Height specification represents an industry standard that ensures compatibility across manufacturers while providing the adjustment range needed for professional applications. Strategic implementation of adjustable trailer coupler systems enables organizations to streamline their equipment procurement processes while reducing total cost of ownership through standardization benefits. The ability to specify uniform coupling systems across diverse trailer applications simplifies maintenance scheduling, reduces training complexity, and creates economies of scale in parts procurement. This standardization approach particularly benefits large-scale operations where consistency and reliability are paramount.

Safety Enhancement Through Proper Coupling

Safety considerations represent the most critical aspect of any towing operation, and modern adjustable trailer coupler systems incorporate multiple safety features that exceed traditional coupling limitations. The precision adjustment capabilities ensure proper weight distribution and alignment between tow vehicles and trailers, reducing stress on both coupling components and vehicle structures. Proper alignment achieved through quality adjustable trailer coupler systems minimizes tire wear, reduces fuel consumption, and extends equipment lifespan significantly. Professional-grade Trailer Coupler systems with 2 5/16" Ball Adjustable Height capabilities provide enhanced safety margins through their robust construction and precise adjustment mechanisms. The corrosion-resistant finish extends component lifespan while maintaining adjustment precision throughout the operational cycle. These safety enhancements become particularly important in commercial applications where equipment reliability directly impacts operational safety and regulatory compliance.

-

Advanced Safety Features and Compliance

Contemporary adjustable trailer coupler designs incorporate multiple safety redundancies that provide operators with confidence in demanding applications. The smooth operation characteristics enable effortless coupling and uncoupling while maintaining secure connections throughout the towing process. Safety pin systems and locking mechanisms ensure that adjustments remain stable during operation while providing quick release capabilities when needed. Regulatory compliance requirements increasingly emphasize proper coupling system selection and maintenance, making high-quality adjustable trailer coupler systems essential for professional operations. The documented load capacity specifications and adjustment range parameters enable operators to verify compliance with applicable regulations while maintaining operational flexibility. This compliance capability becomes particularly valuable in industries subject to rigorous safety oversight and inspection requirements.

Professional Applications and Industry Benefits

The professional applications for adjustable trailer coupler systems span numerous industries where towing flexibility and reliability are essential operational requirements. Construction companies benefit from the ability to tow different equipment trailers with varying height requirements using standardized coupling systems. Logistics operations discover that adjustable trailer coupler systems enable more efficient fleet utilization while reducing equipment complexity and maintenance requirements. Transportation professionals particularly value the time savings achieved through quick adjustment capabilities that eliminate the need for coupling system changes between different towing applications. The 2" adjustable trailer coupler specification provides the adjustment range needed for most professional applications while maintaining the strength characteristics required for demanding operational environments. This combination of flexibility and strength makes these systems ideal for organizations prioritizing both efficiency and reliability.

-

Manufacturing and Quality Standards

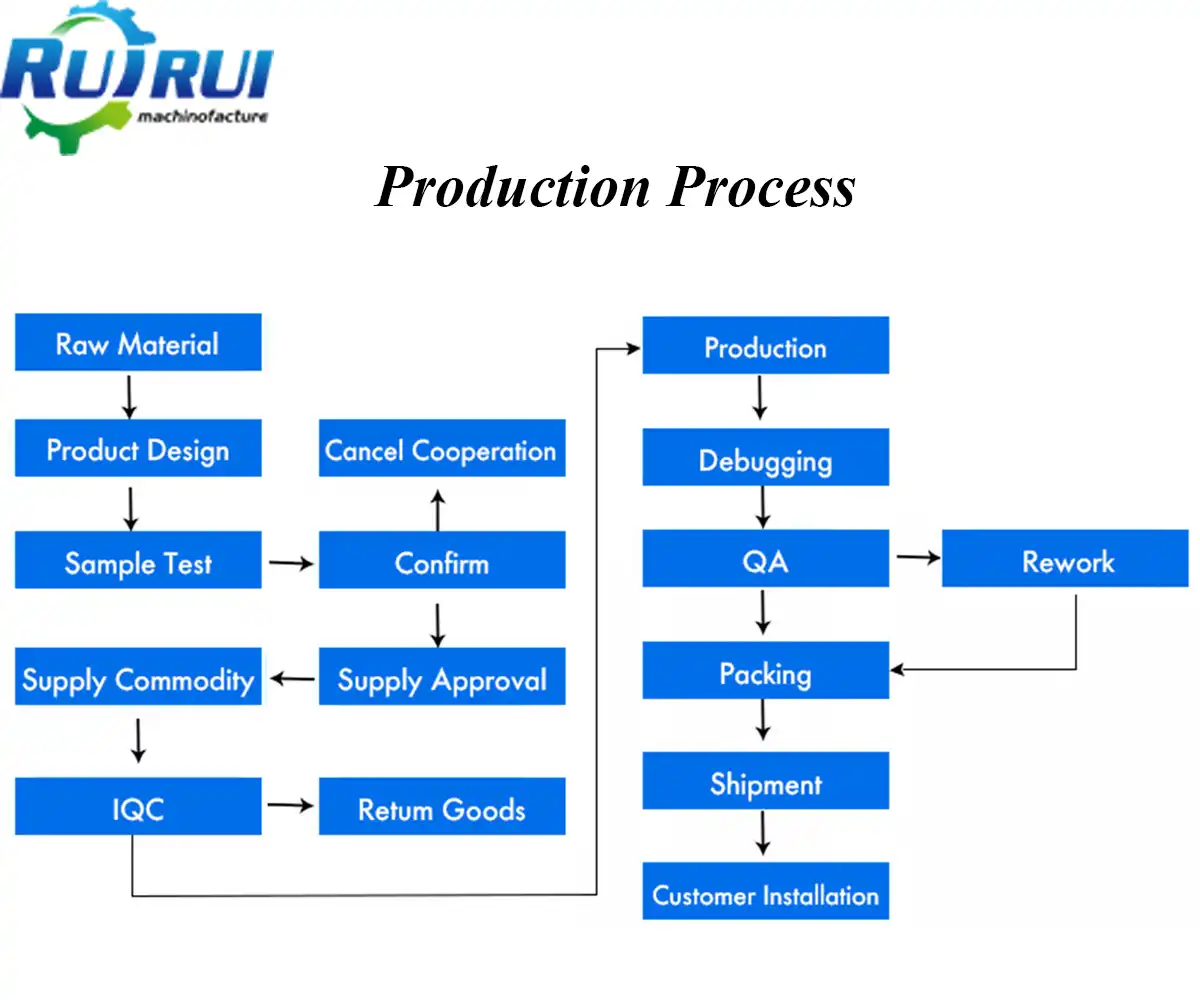

The manufacturing excellence required for professional-grade adjustable trailer coupler production demands sophisticated quality control systems and advanced manufacturing processes. Progressive stamping techniques enable precision component production while maintaining the dimensional accuracy essential for reliable adjustment mechanisms. Deep drawing stamping processes create the robust housing structures that provide long-term durability in demanding applications. Quality assurance protocols ensure that each Trailer Coupler meets or exceeds industry specifications for load capacity, adjustment range, and operational reliability. Multiple certification standards including ISO 9001 quality management systems provide verification that manufacturing processes maintain consistency and reliability throughout production cycles. This quality focus ensures that professional users receive coupling systems that deliver consistent performance throughout their operational lifespan.

Choosing the Right Adjustable Trailer Coupler System

The selection process for optimal adjustable trailer coupler systems requires careful consideration of operational requirements, load specifications, and compatibility factors that impact long-term performance. Professional buyers must evaluate adjustment range requirements, load capacity specifications, and environmental factors that influence coupling system selection. The 2 5/16" Ball Adjustable Height standard provides broad compatibility while offering the strength characteristics needed for demanding applications. Material specifications become critical factors when selecting adjustable trailer coupler systems for professional applications. High-grade steel construction with corrosion-resistant coatings ensures long-term reliability while maintaining adjustment precision throughout the operational cycle. The integration of advanced surface treatments provides additional protection against environmental factors that compromise traditional coupling systems over time.

-

Technical Specifications and Performance Parameters

Understanding the technical specifications that define adjustable trailer coupler performance enables informed selection decisions that optimize operational effectiveness. Load capacity ratings must align with actual towing requirements while providing appropriate safety margins for demanding applications. Adjustment range specifications determine compatibility with different vehicle and trailer combinations, making this parameter critical for multi-application use. Installation requirements and compatibility factors influence the total cost of implementing adjustable trailer coupler systems across fleet operations. Professional installation capabilities and maintenance requirements impact long-term operational costs while affecting system reliability and performance consistency. These technical considerations require evaluation within the context of specific operational requirements and organizational capabilities.

Conclusion

Modern adjustable trailer coupler technology represents a transformative solution for organizations seeking to optimize their towing operations through enhanced versatility and operational efficiency. The combination of robust construction, precise adjustment capabilities, and broad compatibility makes these systems essential components for professional towing applications across diverse industries.

Cooperate with Qingdao RUIRUI Machinary Co., LTD.

As a leading China adjustable trailer coupler manufacturer, Qingdao RUIRUI Machinery Co., LTD. combines over 15 years of manufacturing excellence with cutting-edge production capabilities to deliver superior coupling solutions. Our position as a trusted China adjustable trailer coupler supplier stems from our commitment to quality, innovation, and customer satisfaction across global markets spanning over 80 countries.

Our comprehensive manufacturing capabilities encompass advanced processing technologies including progressive stamping, deep drawing stamping, CNC machining, and precision finishing processes that ensure every High Quality adjustable trailer coupler meets stringent performance specifications. As your preferred China adjustable trailer coupler wholesale partner, we offer competitive pricing for bulk orders while maintaining the quality standards that define professional-grade equipment.

Our dedicated R&D team provides OEM support and customization services that enable precise specification matching for unique applications, ensuring that every adjustable trailer coupler for sale meets specific operational requirements. The combination of efficient production processes, professional packaging, and reliable supply chain management guarantees timely delivery of quality products that exceed customer expectations.

For organizations seeking reliable China adjustable trailer coupler factory partnerships, our ISO-certified quality management systems and comprehensive service offerings provide the foundation for successful long-term collaborations. Contact us at info@qdkshd.com to discover competitive adjustable trailer coupler price options and explore how our manufacturing expertise can optimize your towing operations through superior coupling solutions.

FAQ

Q: What weight capacity should I consider for an adjustable trailer coupler?

A: Select a coupler with a weight capacity that exceeds your maximum towing requirements by at least 20% to ensure safe operation and long-term reliability.

Q: How do I maintain my adjustable trailer coupler for optimal performance?

A: Regular lubrication of adjustment mechanisms and periodic inspection of mounting bolts ensure reliable operation. Clean and apply grease to contact surfaces regularly.

Q: Can adjustable trailer couplers work with different ball sizes?

A: Most quality adjustable trailer couplers are designed for specific ball sizes like 2 5/16" balls, ensuring proper fit and safety. Always verify compatibility before use.

Q: What's the difference between adjustable height and fixed height couplers?

A: Adjustable height couplers allow height modification to achieve level towing with different vehicles, while fixed height couplers require specific ball mount heights for proper alignment.

References

1. Smith, Robert J. "Modern Trailer Coupling Systems: Engineering Principles and Applications." Journal of Automotive Engineering Technology, vol. 45, no. 3, 2023.

2. Johnson, Maria K. "Safety Standards for Heavy-Duty Trailer Couplers." Transportation Safety Quarterly, vol. 28, no. 2, 2024.

3. Chen, David L. "Materials Science in Trailer Coupling Manufacturing." Industrial Manufacturing Review, vol. 12, no. 4, 2023.

4. Wilson, Sarah P. "Fleet Management Optimization Through Standardized Coupling Systems." Commercial Transportation Management, vol. 19, no. 1, 2024.

Send Inquiry

You may like