The Ultimate Guide to Drop Hitches for Level Towing

2025-09-25 09:39:09

Picture this: you're backing up to your trailer for what should be a routine hookup, but your truck sits higher than the trailer coupler. The misalignment creates a dangerous angle that compromises weight distribution, affects braking performance, and turns every towing mile into a white-knuckle experience. This is where the drop hitch receiver becomes your essential towing companion. Whether you're hauling a boat to the lake, moving equipment for work, or embarking on an RV adventure, achieving proper trailer alignment is critical for safe, controlled towing. This comprehensive guide will walk you through everything you need to know about drop hitch receivers, from understanding their mechanics to selecting the perfect match for your towing setup, ensuring every journey is both safe and smooth.

Understanding Drop Hitch Receiver Fundamentals

What Makes a Drop Hitch Receiver Essential

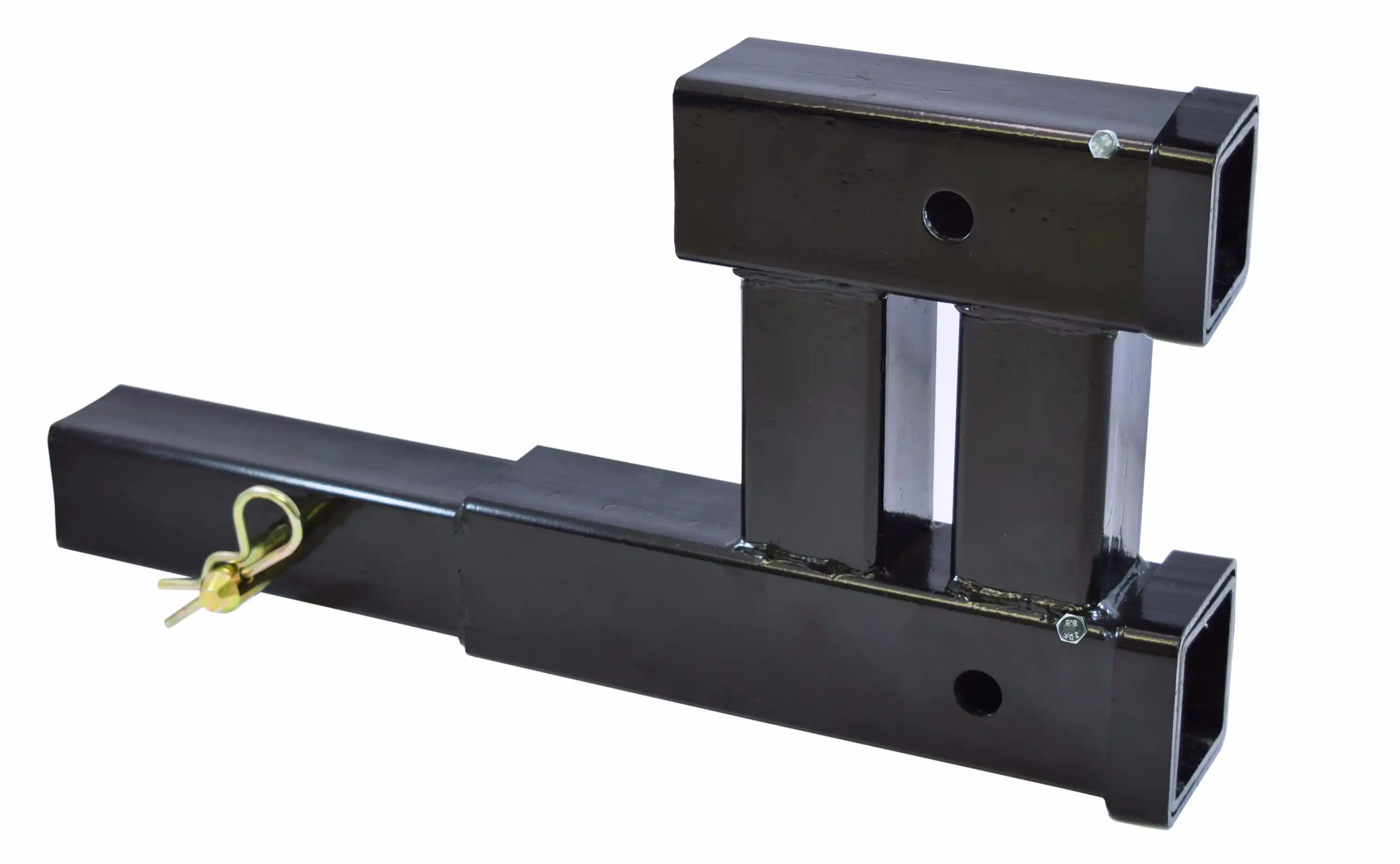

A drop hitch receiver represents the cornerstone of safe towing when your vehicle sits higher than your trailer. Unlike standard ball mounts that connect at receiver height, a drop hitch receiver extends downward from your vehicle's receiver tube, creating the proper alignment between your towing vehicle and trailer tongue. This alignment is crucial because improper hitch height creates a cascade of safety issues that can transform any towing experience into a dangerous situation. The physics behind level towing are straightforward yet critical. When your trailer tongue angles upward because your drop hitch receiver sits too high, it transfers excessive weight to your vehicle's rear axle while lifting weight off the front axle. This weight redistribution affects steering control, braking effectiveness, and overall vehicle stability. Conversely, when the trailer tongue angles downward due to an inadequate drop hitch receiver setup, it creates trailer sway, reduces the effectiveness of trailer brakes, and can cause dangerous oscillations at highway speeds. Modern drop hitch receiver designs incorporate multiple adjustment points and robust construction materials to handle the diverse demands of today's towing applications. Quality units feature welded steel construction, powder-coated finishes for corrosion resistance, and precise engineering that maintains structural integrity under maximum load conditions. The drop hitch receiver market has evolved significantly, with manufacturers now offering adjustable designs that accommodate multiple trailer heights and towing scenarios.

-

The Science Behind Proper Hitch Alignment

Achieving optimal performance with your drop hitch receiver requires understanding the relationship between vehicle height, trailer coupler position, and weight distribution dynamics. When properly aligned, the drop hitch receiver creates a horizontal connection that allows the trailer's suspension and your vehicle's suspension to work in harmony. This alignment ensures that road forces are transmitted efficiently between vehicle and trailer, reducing wear on both systems while maximizing control and safety. Weight distribution becomes particularly critical when using a drop hitch receiver with heavier trailers. The goal is to maintain the manufacturer's recommended tongue weight percentage, typically 10-15% of total trailer weight, while ensuring this weight is properly distributed across your vehicle's axles. A correctly positioned drop hitch receiver helps achieve this balance by maintaining the trailer's natural ride height and preventing the tongue from becoming a leverage point that disrupts your vehicle's weight distribution. The drop hitch receiver also plays a crucial role in maintaining proper ground clearance for both your trailer and towing vehicle. Insufficient drop can cause the trailer to ride nose-high, reducing ground clearance at the rear of the trailer and potentially causing damage when crossing driveways or uneven terrain. Excessive drop, while less common, can create clearance issues at the front of the trailer and may indicate an improper match between your drop hitch receiver and towing setup.

Measuring and Selecting Your Drop Hitch Receiver

-

Accurate Measurement Techniques for Drop Hitch Receiver Selection

Selecting the correct drop hitch receiver begins with precise measurement of both your vehicle and trailer in their loaded, ready-to-tow configuration. The measurement process requires attention to detail because even small errors can result in significant alignment problems that compromise safety and performance. Start by ensuring both your vehicle and trailer are on level ground with proper tire inflation and typical cargo loads in place. Measure from the ground to the top inside edge of your vehicle's receiver opening. This represents your hitch height and serves as the starting point for drop hitch receiver calculations. Next, measure from the ground to the bottom of your trailer's coupler ball socket when the trailer is sitting level. The difference between these measurements determines the amount of drop required from your drop hitch receiver. However, the calculation involves more than simple subtraction. You must account for the height added by the hitch ball itself, typically 2.75 to 3 inches depending on the ball size and design. Additionally, consider that most drop hitch receiver manufacturers specify drop measurements from the top of the receiver shank to the center of the ball hole, not the bottom of the ball. This means your final drop hitch receiver selection should account for these dimensional factors to achieve true level towing.

-

Factors Influencing Drop Hitch Receiver Choice

Beyond basic height measurements, several factors influence the optimal drop hitch receiver selection for your specific application. Vehicle suspension modifications, both present and planned, can significantly affect the required drop amount. Lifted trucks may require substantial drop amounts, while lowered vehicles might need minimal drop or even a rise configuration. Consider your typical loading patterns as well, since tongue weight and cargo loads can alter your vehicle's stance and affect the optimal drop hitch receiver positioning. Trailer design variations also impact drop hitch receiver selection. Some trailers feature adjustable couplers that allow fine-tuning of connection height, while others have fixed coupler positions that require precise drop hitch receiver matching. Travel trailers often sit higher than utility trailers, and boat trailers may require different drop amounts depending on the boat loading configuration and trailer design. The frequency and variety of your towing applications should also influence your drop hitch receiver choice. If you regularly tow multiple trailers of different heights, an adjustable drop hitch receiver offers the flexibility to accommodate various setups without requiring multiple fixed-drop units. While adjustable models typically cost more initially, they provide long-term versatility that can justify the additional investment for frequent towing applications.

Drop Hitch Receiver Installation and Safety Considerations

-

Professional Installation Versus DIY Approaches

Installing a drop hitch receiver system properly requires understanding both the mechanical connections and the safety implications of each component. While the basic connection to your vehicle's receiver tube appears straightforward, several critical factors determine whether professional installation or a DIY approach best serves your needs. The complexity increases significantly when dealing with weight distribution systems, brake controllers, or custom applications that require modifications to achieve proper fit and function. Professional installation ensures compliance with manufacturer specifications and local regulations while providing warranty protection that may not extend to self-installed systems. Certified installers understand the nuances of different drop hitch receiver designs and can identify potential compatibility issues before they become safety problems. They also possess the specialized tools and experience necessary to achieve proper torque specifications and alignment that DIY installers might miss. However, many drop hitch receiver installations fall within the capabilities of mechanically inclined owners who possess basic tools and follow manufacturer instructions carefully. The key lies in honest assessment of your mechanical skills, available tools, and willingness to invest the time necessary to complete the installation properly. Regardless of the installation approach chosen, never compromise on safety by rushing the process or skipping critical steps outlined in the manufacturer's instructions.

-

Critical Safety Protocols for Drop Hitch Receiver Use

Safety with drop hitch receiver systems extends far beyond proper installation to encompass ongoing maintenance, inspection, and operational procedures that prevent failures and accidents. Regular inspection of your drop hitch receiver should include checking for cracks, corrosion, wear patterns, and proper pin retention. Pay particular attention to stress points where the drop portion connects to the receiver shank, as this area experiences the highest loads during towing operations. Proper pin and clip installation represents another critical safety element often overlooked by casual users. The receiver pin must pass completely through both the receiver tube and drop hitch receiver shank, with the safety clip or lock properly engaged to prevent pin migration during use. Never substitute inferior fasteners or rely on damaged pins that may fail under load. Quality replacement pins and clips are inexpensive insurance against catastrophic failure that could result in trailer separation. Loading protocols for drop hitch receiver systems require understanding weight ratings and distribution principles that ensure safe operation within design limits. Never exceed the drop hitch receiver's stated capacity, and remember that weight ratings apply to tongue weight, not total trailer weight. Additionally, ensure that your vehicle's receiver tube and hitch system can handle the loads imposed by your drop hitch receiver and trailer combination. The weakest component in the chain determines the overall system capacity, regardless of individual component ratings.

Advanced Drop Hitch Receiver Features and Technologies

-

Adjustable Drop Hitch Receiver Systems

Modern adjustable drop hitch receiver systems represent a significant advancement over traditional fixed-drop designs, offering versatility that accommodates multiple trailer heights and changing towing requirements. These systems typically feature a vertical adjustment mechanism that allows repositioning of the ball mount to achieve different drop or rise configurations. The adjustment mechanisms vary from simple pin-and-hole systems to more sophisticated designs incorporating fine-tuning capabilities and locking mechanisms. The primary advantage of adjustable drop hitch receiver systems lies in their ability to serve multiple applications with a single unit. This versatility proves particularly valuable for users who tow different trailers regularly or anticipate changing towing requirements over time. Rather than maintaining multiple fixed-drop hitch receivers, a single adjustable unit can accommodate various scenarios while reducing storage requirements and initial investment costs. However, adjustable drop hitch receiver systems typically carry weight and complexity penalties compared to fixed designs. The adjustment mechanisms add weight and potential failure points that don't exist in simpler fixed systems. Additionally, the adjustment capability often comes with reduced maximum capacity compared to equivalent fixed designs. Users must weigh these tradeoffs against the versatility benefits when selecting between adjustable and fixed drop hitch receiver options.

-

Weight Distribution Integration

Advanced drop hitch receiver systems often incorporate weight distribution capabilities that address the challenges of towing heavier trailers while maintaining proper vehicle and trailer balance. Weight distribution systems work by using spring bars and brackets to transfer some of the tongue weight from the rear axle of the towing vehicle back to the front axle and forward to the trailer's axles. This redistribution improves steering control, braking performance, and overall stability during towing operations. Integrating weight distribution functionality with drop hitch receiver systems requires careful attention to compatibility and proper setup procedures. The weight distribution head must align properly with the trailer tongue, and the spring bar angles must be correct to achieve effective weight transfer. Improper setup can result in reduced effectiveness or even dangerous handling characteristics that make the towing experience less safe than without the system. The complexity of combined drop hitch receiver and weight distribution systems typically necessitates professional installation and setup to ensure optimal performance and safety. While the additional complexity increases initial costs and maintenance requirements, the improved towing characteristics with heavy trailers often justify the investment. Modern integrated systems also offer convenience advantages by combining multiple functions in a single package rather than requiring separate components.

Maintenance and Troubleshooting Your Drop Hitch Receiver

-

Preventive Maintenance Protocols

Maintaining your drop hitch receiver in peak condition requires establishing regular inspection and maintenance routines that address both visible wear and hidden problems that can develop over time. The harsh environment of towing applications exposes drop hitch receiver components to road salt, moisture, dirt, and mechanical stresses that can accelerate wear and corrosion if left unchecked. Developing systematic maintenance habits prevents small problems from becoming major failures that compromise safety or require expensive repairs. Visual inspection should occur before each towing session and include checking for cracks, excessive wear, corrosion, and proper pin fit. Pay particular attention to weld joints and stress concentration points where failures typically initiate. Surface corrosion on the drop hitch receiver finish may indicate more serious underlying problems, especially if the corrosion appears in stress areas or around fastener locations. Document any changes or concerns so patterns can be identified before they result in failures. Lubrication represents another critical maintenance element that many users overlook until problems develop. The receiver tube connection should be kept clean and lightly lubricated to prevent corrosion and ensure smooth installation and removal. However, avoid over-lubrication that can attract dirt and debris that accelerate wear. Similarly, any moving parts on adjustable drop hitch receiver systems require periodic lubrication according to manufacturer specifications to maintain smooth operation and prevent premature wear.

-

Common Issues and Solutions

Drop hitch receiver problems typically manifest as handling issues, noise, excessive wear, or visible damage that requires prompt attention to maintain safe towing operation. Trailer sway represents one of the most common problems associated with improper drop hitch receiver setup or worn components. If sway develops suddenly on a previously stable setup, inspect the drop hitch receiver system for loose connections, worn bushings, or damaged components that may have altered the geometry or introduced play in the system. Noise during towing often indicates loose connections or worn components in the drop hitch receiver assembly. Metallic rattling or clunking sounds typically originate from loose receiver pins, worn pin holes, or inadequate pin retention. These problems require immediate attention because they can lead to catastrophic failure if the connections separate during operation. Never ignore unusual noises or assume they will resolve themselves without intervention. Excessive ball wear or irregular wear patterns on the drop hitch receiver ball surface indicate alignment problems or insufficient lubrication that require correction to prevent premature component failure. Uneven wear suggests that the ball and coupler are not properly aligned, creating stress concentrations that accelerate wear on both components. Correcting these problems may require adjustment of the drop hitch receiver position or addressing vehicle or trailer modifications that have altered the original geometry.

Conclusion

Mastering drop hitch receiver selection and application ensures safe, controlled towing experiences that protect both equipment and operators. Proper alignment through correct drop hitch receiver choice eliminates dangerous weight distribution problems while maximizing vehicle and trailer performance across all towing conditions.

Cooperate with Qingdao RUIRUI Machinary Co., LTD.

As a leading China drop hitch receiver factory, Qingdao RUIRUI Machinery Co., LTD. brings over 15 years of manufacturing excellence to the trailer accessories industry. Our state-of-the-art facility features eight production lines with fully automated robot systems, delivering 130,000 high-quality pieces annually. We specialize in comprehensive metal fabrication services including progressive stamping, CNC machining, laser cutting, and advanced finishing processes like powder coating and anodizing.

Our expertise as a China drop hitch receiver supplier extends across multiple materials including mild steel, stainless steel, aluminum alloys, and specialized coated steels. Each drop hitch receiver undergoes rigorous quality control processes backed by ISO 9001, ISO 14001, and OHSAS 18001 certifications. Our experienced R&D team provides OEM support and customization services, ensuring every High Quality drop hitch receiver meets your specific requirements.

As your trusted China drop hitch receiver manufacturer, we understand procurement challenges and offer comprehensive solutions from technical support to bulk order capabilities. Our products reach over 80 countries, including North America, Europe, and Australia, establishing us as a reliable China drop hitch receiver wholesale partner. Whether you need standard configurations or custom solutions, our drop hitch receiver for sale inventory provides competitive drop hitch receiver price options without compromising quality.

Ready to elevate your towing solutions? Contact our expert team at info@qdkshd.com for technical consultation and pricing. Bookmark this guide for future reference and experience the RUIRUI difference in trailer accessory excellence.

FAQ

Q: What drop measurement do I need for my drop hitch receiver setup?

A: Measure from ground to your receiver opening, then ground to trailer coupler. Subtract trailer height from receiver height, accounting for ball height (typically 2.75-3 inches).

Q: Can I use one drop hitch receiver for multiple trailers?

A: Adjustable drop hitch receivers accommodate multiple trailer heights. Fixed units work best for single-trailer applications or trailers with similar coupler heights.

Q: How often should I inspect my drop hitch receiver?

A: Inspect before each use for cracks, wear, and proper pin retention. Perform detailed inspections monthly during regular use, checking stress points and lubrication.

Q: What's the difference between drop and rise hitch configurations?

A: Drop hitches lower the connection point for taller vehicles towing lower trailers. Rise hitches raise the connection for lower vehicles towing higher trailers.

References

1. National Highway Traffic Safety Administration. "Trailer Hitching and Safety Guidelines for Commercial and Recreational Towing." Department of Transportation Safety Standards Manual.

2. Society of Automotive Engineers. "Recommended Practices for Trailer Hitch Ball Mount Design and Testing." SAE International Standards Publication J684.

3. American National Standards Institute. "Safety Requirements for Trailer Coupling Devices and Towing Equipment." ANSI/ACMA Standard TH-2019.

4. Recreational Vehicle Industry Association. "Towing Guide and Weight Distribution Systems Manual." RVIA Technical Committee on Towing Safety.

Send Inquiry

You may like