Trends in Custom-Machined Metal Hinges for Modern Manufacturing

2025-10-22 10:46:22

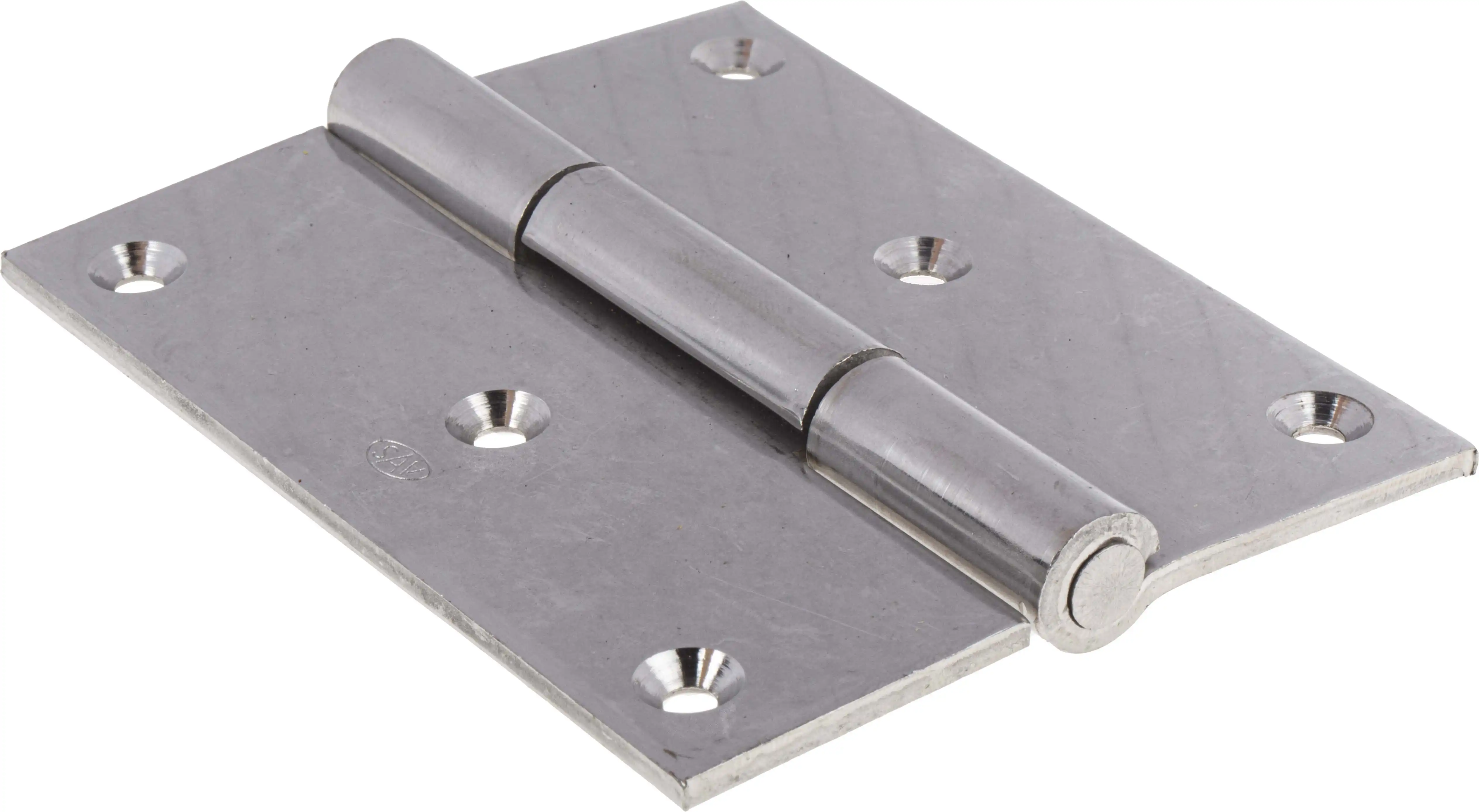

Are you struggling to find custom-machined metal hinges that deliver precision, durability, and cost-effectiveness for your manufacturing operations? Modern production environments demand advanced hinge solutions that go beyond standard components to meet increasingly complex technical specifications and demanding application requirements. This comprehensive guide explores the latest trends shaping the custom-machined metal hinge industry and how businesses can leverage innovative solutions to stay competitive.

Evolution of Custom-Machined Metal Hinge Technology

The manufacturing landscape has undergone significant transformation as industries shift toward more specialized and sophisticated hinge solutions. Custom-machined metal hinges have evolved from simple mechanical connectors into precision-engineered components that support critical applications across aerospace, industrial machinery, medical devices, and specialized equipment sectors. This evolution reflects broader industry trends toward automation, quality enhancement, and supply chain reliability.

-

Advanced Machining Capabilities Driving Innovation

Modern manufacturers leverage state-of-the-art CNC machining, laser cutting, and precision stamping technologies to produce custom-machined metal hinges with exceptional accuracy. Qingdao RUIRUI Machinery Co., LTD stands at the forefront of this technological advancement, operating eight specialized production lines with fully automated robot systems. Their commitment to transforming emerging technologies into practical manufacturing solutions ensures that each custom-machined metal hinge meets the most demanding performance standards. The company's progressive stamping capabilities, combined with advanced polishing, deburring, and electrophoresis processes, deliver hinges that exceed industry expectations for strength, finish quality, and component longevity.

-

Material Selection and Performance Optimization

Material science continues to advance, providing manufacturers with expanded options for creating custom-machined metal hinges suited to specific environmental conditions. Stainless steel hinges offer corrosion resistance for marine and coastal applications, while aluminum alloys provide lightweight solutions for aerospace components. Cold-rolled steel delivers exceptional strength for industrial machinery, while brass and copper variants serve specialized electrical and decorative applications. RUIRUI's expertise in metal stamping encompasses diverse material categories including mild steel, coated steel, aluminum alloys, and titanium, ensuring that each metal hinge receives appropriate treatment through advanced processing technologies tailored to material-specific requirements.

Industry Applications and Market Demand for Metal Hinge Solutions

The demand for sophisticated custom-machined metal hinges extends across multiple industrial sectors, each with unique performance requirements and operational constraints. Heavy-duty industrial applications demand hinges capable of withstanding extreme loads and environmental stresses, while precision equipment requires components that maintain consistent performance over extended operational cycles. Aerospace applications demand hinges engineered to precise weight specifications while maintaining structural integrity under critical stress conditions.

-

Aerospace and Defense Specifications

Aerospace manufacturers require custom-machined metal hinges engineered to military specifications with precision-drilled holes designed for unparalleled structural integrity. These hinges achieve exceptional strength-to-weight ratios, making them essential for landing gear doors, control surfaces, and access panel applications where component reliability directly impacts flight safety. The machining processes must deliver nanometer-level precision alongside material consistency that supports repeat performance across thousands of operational cycles.

-

Industrial and Machinery Applications

Heavy machinery and industrial equipment manufacturers depend on custom-machined metal hinges that withstand constant operational stress and environmental exposure. These applications frequently require load capacities ranging from several thousand pounds for standard operations to extreme specifications for specialized heavy-duty equipment. Weld-on hinges, pin-type connections, and specialty fabrications allow engineers to design equipment configurations optimized for specific industrial processes while maintaining long-term reliability and minimal maintenance requirements.

Manufacturing Excellence and Quality Assurance Standards

Manufacturers of custom-machined metal hinges must maintain rigorous quality control protocols ensuring consistent component performance and durability throughout production cycles. ISO 9001, ISO 14001, and ISO 20000 certifications establish frameworks for quality management, environmental responsibility, and operational efficiency that protect manufacturing operations and customer satisfaction. Qingdao RUIRUI Machinery has achieved these international certifications alongside OHSAS 18001 occupational health and safety standards, demonstrating organizational commitment to excellence across all operational dimensions.

-

Secondary Processing and Surface Treatment

The secondary processing stage distinguishes premium metal hinge manufacturers from commodity producers. Advanced techniques including sonic cleaning, powder coating, plating, anodizing, and electrophoresis impart protective properties while enhancing aesthetic appeal and functional performance. These processes extend component lifespan, improve corrosion resistance, and can provide specialized electrical properties required for particular applications. RUIRUI's mastery of these secondary processes ensures that each custom-machined metal hinge emerges with superior surface quality, consistent finish characteristics, and enhanced durability suited to demanding operational environments.

-

Utility Model Patents and Design Innovation

Leading manufacturers invest significantly in research and development to create innovative hinge designs addressing specific industry challenges and emerging market requirements. Patent protection for utility models and design innovations provides competitive advantages while demonstrating organizational commitment to continuous improvement. RUIRUI's portfolio of utility model patents and design patents reflects the company's dedication to advancing metal hinge technology through systematic innovation and engineering excellence.

Supply Chain Reliability and Production Capacity

Modern manufacturing enterprises require hinge suppliers offering dependable delivery schedules, consistent quality, and sufficient production capacity to support scaling operations. Manufacturers with multiple production lines and automated systems can fulfill diverse orders ranging from specialized single-component requirements to large-volume commercial shipments. RUIRUI's annual production capacity of 130,000 pieces across eight production lines demonstrates manufacturing capability supporting both specialized requirements and high-volume commercial applications.

-

Global Distribution and Market Reach

Established hinge manufacturers serve diverse global markets, exporting finished products to more than eighty countries across Europe, North America, South America, Asia, and Australia. This international reach reflects quality recognition and supply chain reliability that supports multinational manufacturers and distributed supply chains. OEM support capabilities enable collaboration with original equipment manufacturers developing specialized applications requiring tailored component specifications and production support throughout product development cycles.

-

Customization and Product Design Services

One-size-fits-all approaches fail to address the diversity of requirements across manufacturing sectors and specialized applications. Professional metal hinge manufacturers offer comprehensive customization services including size modifications, material selection optimization, and specialized coating or surface treatment applications. Technical support teams collaborate with engineering departments to ensure component specifications align with application requirements while maintaining cost effectiveness and delivery reliability. RUIRUI's commitment to customization extends from initial concept development through production support, enabling customers to translate design requirements into production-ready components meeting performance, cost, and delivery objectives.

Conclusion

The custom-machined metal hinge industry continues evolving toward greater precision, material sophistication, and application-specific optimization. Manufacturing enterprises benefit from partnering with experienced, technology-forward providers offering comprehensive capabilities spanning material selection, advanced machining processes, quality assurance protocols, and responsive customer support.

Cooperate with Qingdao RUIRUI Machinery Co., LTD.

Partner with a China custom-machined metal hinge factory offering comprehensive manufacturing expertise, advanced production capabilities, and responsive customer support. As a trusted China custom-machined metal hinge supplier and leading China custom-machined metal hinge manufacturer, RUIRUI delivers high-quality custom-machined metal hinges for sale with competitive custom-machined metal hinge pricing. Contact our team today for wholesale opportunities and bulk custom-machined metal hinge orders. Reach out to info@qdkshd.com to explore how our solutions address your manufacturing requirements and support operational excellence.

References

1. Title: "Innovations in Metal Stamping and CNC Precision Manufacturing for Aerospace Applications"

Author: Engineering Innovation Institute, Journal of Advanced Manufacturing Technology, 2024

2. Title: "Custom Hinge Design and Fabrication Standards in Industrial Equipment Manufacturing"

Author: Dr. Michael Chen, International Journal of Metal Fabrication and Assembly, 2023

3. Title: "Quality Management Systems in Metal Component Manufacturing: ISO Standards and Industry Best Practices"

Author: Manufacturing Standards Institute, Global Quality Management Review, 2024

4. Title: "Surface Treatment Processes and Corrosion Resistance in Specialized Metal Hinge Applications"

Author: Prof. Robert Williams, Materials Science and Engineering Quarterly, 2023

Send Inquiry

You may like