Understanding Trailer Pin Types: A Comprehensive Guide

2025-09-30 11:28:18

Picture this scenario: you're preparing for an important delivery or weekend adventure, your trailer is loaded and ready, but suddenly you realize your trailer hitch pin has failed or doesn't fit properly. This moment of frustration could have been avoided with proper knowledge about trailer pin types and their applications. Understanding trailer pin types is crucial for anyone involved in towing operations, whether you're managing a commercial fleet, hauling construction equipment, or enjoying recreational activities. This comprehensive guide will equip you with the essential knowledge to select the right trailer hitch pin for your specific needs, ensuring safety, reliability, and peace of mind during your towing operations.

Essential Trailer Hitch Pin Types and Their Applications

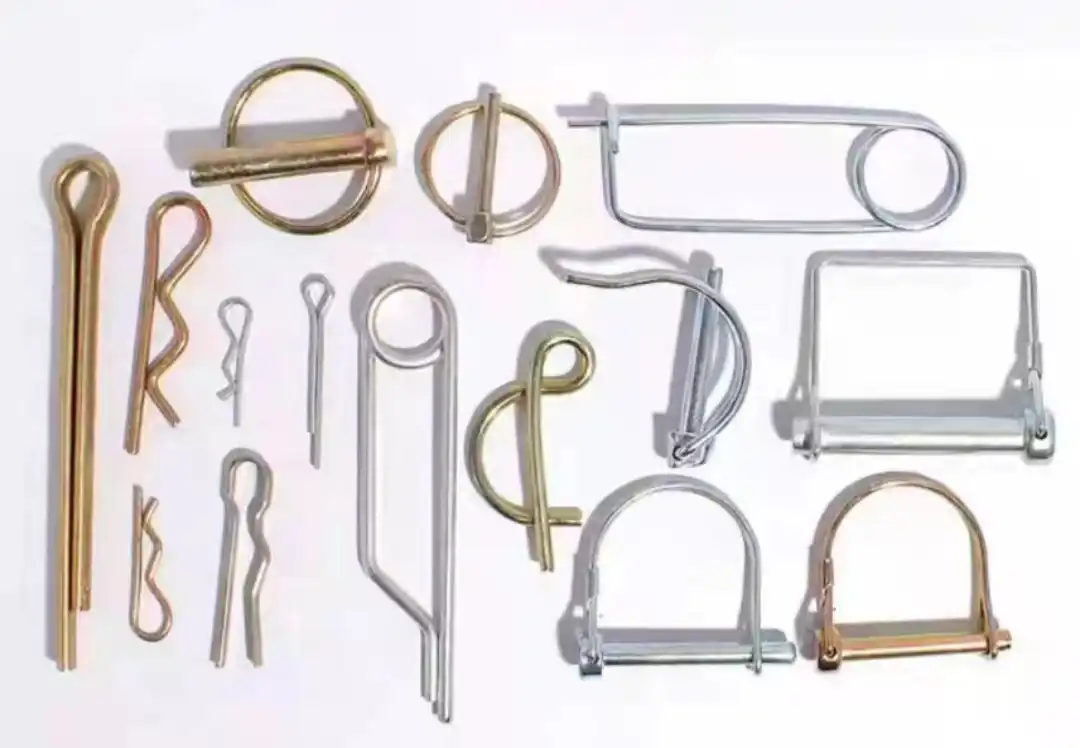

The world of trailer pins encompasses various specialized components, each designed for specific towing applications and load requirements. Understanding these different types is fundamental to making informed decisions about your towing equipment and ensuring optimal performance in diverse operational environments.

-

Receiver Trailer Hitch Pin Fundamentals

The receiver trailer hitch pin serves as the primary connection point between your vehicle's hitch receiver and the trailer's coupler or ball mount. These pins are engineered to withstand tremendous forces while maintaining secure connections throughout the towing process. A properly selected receiver trailer hitch pin ensures that your trailer remains securely attached to your vehicle, even under the most demanding conditions such as emergency braking, sharp turns, or when navigating challenging terrain. Modern receiver trailer hitch pins are manufactured using high-grade materials, typically featuring steel construction with specialized coatings to resist corrosion and wear. The engineering behind these components involves precise calculations of load distribution, stress concentration points, and material fatigue resistance. This attention to detail ensures that each trailer pin can handle its rated capacity while providing a safety margin that protects against unexpected load variations or operational stresses.

-

Linch Pin Technology and Applications

Linch pins represent an evolution in trailer pin technology, incorporating self-locking mechanisms that eliminate the need for separate clips or fasteners. These innovative pins feature spring-loaded locking systems that automatically engage when the pin is fully inserted, providing immediate feedback to the operator and ensuring proper installation. The trailer hitch pin design of linch pins makes them particularly valuable in commercial applications where time efficiency and reliability are paramount concerns. The versatility of linch pins extends across multiple industries and applications. In agricultural settings, these pins secure implements to tractors and connect various pieces of farming equipment. Construction operations rely on linch pins to attach trailers to heavy equipment and ensure secure connections during material transport. The automotive industry utilizes these pins in recreational vehicle applications, where ease of use and dependable performance enhance the overall towing experience for consumers.

Safety and Security Considerations for Trailer Pin Selection

Safety remains the most critical factor when selecting and using trailer pins in any application. The consequences of pin failure can range from property damage to serious accidents, making proper selection and maintenance essential responsibilities for every operator involved in towing operations.

-

Load Capacity and Material Specifications

Understanding load capacity requirements forms the foundation of safe trailer pin selection. Each trailer pin is rated for specific weight limits, and exceeding these limits can result in catastrophic failure. The receiver trailer hitch pin you choose must not only handle the static weight of your trailer and cargo but also accommodate dynamic forces generated during acceleration, braking, and turning maneuvers. Material specifications play equally important roles in ensuring long-term reliability and safety. High-grade steel pins offer superior strength and durability, while specialized coatings provide protection against environmental factors such as salt, moisture, and chemicals. Some applications may require stainless steel or aluminum alloy pins, particularly in marine environments where corrosion resistance is paramount. The manufacturing process also influences pin performance, with precision machining and heat treatment contributing to enhanced strength and longevity.

-

Installation and Inspection Protocols

Proper installation procedures ensure that trailer pins perform as designed throughout their service life. The process begins with thorough inspection of both the pin and the receiving components, checking for signs of wear, damage, or contamination that could compromise performance. The trailer hitch pin must be inserted fully and secured according to manufacturer specifications, with all locking mechanisms properly engaged. Regular inspection schedules should be established based on usage frequency and operating conditions. High-use applications may require daily inspections, while occasional recreational use might necessitate checks before each outing. Inspection protocols should include visual examination of the pin surface, verification of locking mechanism operation, and assessment of wear patterns that might indicate misalignment or excessive stress. Documentation of inspection results helps track pin performance over time and identify trends that might predict maintenance needs or replacement requirements.

Advanced Manufacturing and Quality Standards

The manufacturing process for trailer pins involves sophisticated engineering and quality control measures that ensure consistent performance across diverse applications. Understanding these processes helps users appreciate the value of high-quality components and make informed purchasing decisions.

-

Precision Manufacturing Techniques

Modern trailer pin manufacturing employs advanced techniques such as CNC machining, precision forging, and specialized heat treatment processes. These methods ensure dimensional accuracy, consistent material properties, and optimal surface finishes that contribute to enhanced performance and longevity. The receiver trailer hitch pin manufacturing process begins with material selection, where high-grade steel alloys are chosen for their strength characteristics and workability. Computer-controlled machining centers produce pins with tolerances measured in thousandths of an inch, ensuring proper fit and function in standard hitch receivers. Heat treatment processes optimize material hardness and toughness, creating pins that resist deformation under load while maintaining sufficient ductility to prevent brittle failure. Surface treatments such as zinc plating, powder coating, or specialized corrosion-resistant finishes provide protection against environmental factors while maintaining the pin's aesthetic appearance.

-

Quality Assurance and Testing Standards

Comprehensive quality assurance programs ensure that every trailer pin meets or exceeds industry standards and customer expectations. Testing protocols include tensile strength verification, fatigue resistance evaluation, and corrosion resistance assessment. These tests simulate real-world operating conditions and verify that pins will perform reliably throughout their expected service life. International quality standards such as ISO 9001 provide frameworks for consistent manufacturing processes and continuous improvement initiatives. Many manufacturers also implement additional certifications such as ISO 14001 for environmental management and OHSAS 18001 for occupational health and safety. These comprehensive quality systems ensure that trailer hitch pin production meets the highest standards for performance, reliability, and environmental responsibility.

Industry-Specific Applications and Requirements

Different industries have unique requirements for trailer pins, influenced by factors such as load characteristics, environmental conditions, and operational procedures. Understanding these specific needs helps ensure optimal component selection and performance in specialized applications.

-

Commercial Transportation and Fleet Operations

Commercial transportation operations demand trailer pins that provide consistent performance under heavy-duty conditions. Fleet managers must consider factors such as driver skill levels, maintenance schedules, and operational environments when selecting pins for their vehicles. The receiver trailer hitch pin choices for commercial applications often emphasize durability and ease of use, reducing maintenance requirements and minimizing downtime. Long-haul trucking operations require pins that can withstand extended use and harsh environmental conditions. These applications benefit from pins with enhanced corrosion resistance and wear characteristics that maintain performance over hundreds of thousands of miles. Local delivery services may prioritize ease of installation and removal, allowing drivers to quickly connect and disconnect trailers during busy delivery schedules.

-

Construction and Heavy Equipment Applications

Construction environments present unique challenges for trailer pins, including exposure to dirt, debris, chemicals, and extreme loads. The trailer pin selections for these applications must withstand contamination while maintaining secure connections under dynamic loading conditions. Construction equipment trailers often carry loads that approach or exceed the rated capacity of standard pins, requiring careful selection and regular inspection to ensure safe operation. Heavy equipment transport involves specialized trailers designed to carry bulldozers, excavators, and other large machinery. These applications require trailer hitch pins with exceptional strength characteristics and precise fit tolerances to ensure safe transport of valuable equipment. The pins must also accommodate the unique loading and unloading procedures associated with heavy equipment transport, including the use of ramps and specialized tie-down systems.

Conclusion

Understanding trailer pin types is essential for safe and efficient towing operations across all industries and applications. Proper selection, installation, and maintenance of these critical components ensure reliable performance while protecting valuable equipment and personnel. The investment in high-quality trailer hitch pins pays dividends through reduced downtime, enhanced safety, and improved operational efficiency.

Cooperate with Qingdao RUIRUI Machinary Co., LTD.

As a leading China trailer hitch pin manufacturer established in 2016, Qingdao RUIRUI Machinary Co., LTD. combines over 15 years of management experience with cutting-edge manufacturing capabilities to deliver superior trailer hitch pin solutions. Our ISO-certified facility features eight production lines with annual output capacity of 130,000 pieces, utilizing advanced CNC machining, laser cutting, and specialized coating processes to ensure exceptional quality and reliability.

Our comprehensive manufacturing capabilities encompass progressive stamping, deep drawing, anodizing, and electrophoresis processes, working with materials including mild steel, stainless steel, aluminum alloys, and brass. As your trusted China trailer hitch pin supplier, we provide customized solutions with MOQ of 1000 pieces, professional OEM support, and competitive trailer hitch pin price structures. Our high quality trailer hitch pin products serve commercial fleets, construction equipment, and recreational applications worldwide.

Experience the advantages of partnering with a premier China trailer hitch pin factory that prioritizes innovation, quality, and customer satisfaction. Our trailer hitch pin for sale includes various sizes and specifications, all backed by comprehensive technical support and efficient global shipping. For inquiries about our China trailer hitch pin wholesale opportunities, contact us at info@qdkshd.com.

FAQ

Q: What is the difference between a standard hitch pin and a receiver trailer hitch pin?

A: A receiver trailer hitch pin is specifically designed to fit through hitch receivers and secure ball mounts or other accessories, while standard hitch pins may be used for various trailer connections.

Q: How do I determine the correct trailer hitch pin size for my application?

A: Measure your hitch receiver opening and check your trailer's weight capacity requirements. Most receivers use 1/2" or 5/8" diameter pins with lengths ranging from 3" to 5".

Q: What maintenance is required for trailer pins?

A: Regular visual inspection for wear, corrosion, or damage, plus periodic lubrication of locking mechanisms. Replace pins showing signs of deformation or excessive wear immediately.

Q: Can I use a larger diameter pin than specified for my hitch receiver?

A: No, always use the exact diameter specified for your hitch receiver. Oversized pins won't fit properly, while undersized pins create dangerous slack that can lead to failure.

References

1. "Trailer Hitch Safety and Installation Guidelines" by National Highway Traffic Safety Administration, Washington D.C.

2. "Heavy-Duty Trailer Pin Engineering Standards" by Society of Automotive Engineers Technical Committee, Detroit Michigan

3. "Commercial Vehicle Towing Equipment Specifications" by American Trucking Association Safety Council, Arlington Virginia

4. "Agricultural Equipment Attachment Systems Manual" by American Society of Agricultural and Biological Engineers, St. Joseph Michigan

Send Inquiry

You may like