What are the different types of hitch pins?

2025-03-03 14:46:25

Hitch pins are essential components in the towing and transportation industry, serving as crucial connecting elements that secure various attachments to vehicles and equipment. These small but mighty hardware pieces come in various designs and specifications, each tailored to fulfill specific functions across multiple applications. Understanding the different types of hitch pins available in the market can help you select the most appropriate option for your particular needs, ensuring safety, reliability, and efficiency in your operations.

Hitch pins are specialized fasteners designed to secure connections between towing vehicles and trailers or other attachments. These pins come in various configurations, including standard clevis pins, lynch pins, L-pins, snap pins, bridge pins, and specialized agricultural hitch pins. Each type offers specific benefits in terms of security, ease of use, and load capacity. The selection of the appropriate hitch pin depends on the specific application, required strength, and operating environment. Quality manufacturers like RUIRUI Machinery ensure these pins meet industry standards through precision manufacturing processes and high-grade materials, resulting in reliable connections that ensure safety in towing and attachment operations.

Common Types of Hitch Pins and Their Applications

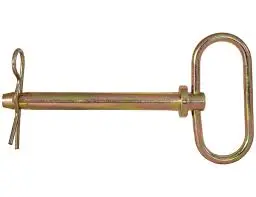

Standard Clevis Pins

Standard clevis pins represent one of the most recognizable and widely utilized hitch pin varieties in the market today. These pins feature a cylindrical shaft with a hole at one end for a cotter pin or clip to prevent accidental removal. RUIRUI Machinery's standard clevis hitch pins are manufactured using high-quality 4.8 carbon steel or 304 stainless steel, ensuring durability and resistance to harsh conditions. The advanced galvanized technology applied to carbon steel pins effectively prevents rust formation, while the stainless steel variants are particularly suitable for high-temperature or high-salinity environments where corrosion resistance is crucial. These pins serve as perfect cotter pin replacements and are necessary for trailer ball pins, push and pull pins, and keeper pins. With RUIRUI's commitment to precision manufacturing, each pin features a smooth surface without burrs, providing easy insertion and removal while maintaining a secure connection. These hitch pins are extensively used in towing applications, securing trailers and boats to vehicles, as well as in construction equipment where attachments need to be securely connected with minimal play.

Lynch Pins

Lynch pins represent a significant advancement in hitch pin technology, offering enhanced security features that make them ideal for applications where vibration and movement might cause standard pins to work loose. RUIRUI Machinery produces premium-quality lynch pins designed with a distinctive hairpin or U-shaped body and a spring-loaded locking mechanism that snaps through the clevis hole, creating a reliable retention system. These specialized hitch pins provide superior holding power and are manufactured using RUIRUI's advanced metal stamping capabilities, which include progressive stamping and deep drawing techniques. The company's expertise in materials processing allows them to offer these pins in various finishes including powder coating, plating, and electrophoresis, extending their service life even in challenging outdoor conditions. Lynch pins have become particularly valuable in agricultural applications, where they secure implements to tractors and other machinery that operate over rough terrain. Their ease of insertion and removal, combined with their self-retaining properties, makes them the preferred choice for farm equipment, engines, trucks, and lawn and garden equipment. RUIRUI's manufacturing process ensures each lynch pin meets stringent quality standards, with detailed quality files established from the beginning of production.

Snap Lock Pins

Snap lock pins, also known as quick-release pins, represent the pinnacle of convenience in the hitch pin family, offering tool-free operation while maintaining exceptional security. RUIRUI Machinery's snap lock hitch pins feature a spring-loaded ball bearing mechanism that locks the pin in place when inserted and releases with a simple pull of the ring or button. These sophisticated pins are produced through RUIRUI's comprehensive metal manufacturing processes, which include CNC machining for precision components and advanced surface treatments like anodizing and polishing for superior finish quality. Available in both carbon steel and stainless steel versions, these pins can be customized to meet specific size requirements, with MOQs starting at just 100 pieces. The snap lock design makes these hitch pins particularly valuable in recreational vehicles and marine applications, where frequent coupling and uncoupling occur. They serve as crucial components for securing tow bars, docking systems, and boat trailer attachments. The convenience of quick release combined with the security of positive locking makes these pins ideal for applications where time efficiency matters without compromising on connection integrity. RUIRUI's commitment to quality assurance, evidenced by their ISO certifications, ensures each snap lock pin delivers consistent performance in demanding environmental conditions.

Specialty Hitch Pins for Heavy-Duty Applications

Bridge Pins

Bridge pins represent the heavy-duty category of hitch pins, specifically engineered to withstand extreme loads and stresses encountered in industrial and construction environments. RUIRUI Machinery designs and manufactures these robust hitch pins using their specialized metal stamping processes and premium materials selection. Their bridge pins are typically crafted from high-grade carbon steel or stainless steel, with diameter options customized to the specific application requirements. The company's advanced manufacturing capabilities, including laser cutting, welding, and CNC processing, ensure precise dimensional accuracy and structural integrity in every pin produced. These heavy-duty hitch pins feature reinforced shafts and specialized retention mechanisms designed to prevent loosening even under severe vibration and shock loads. RUIRUI's bridge pins undergo rigorous quality control procedures, with inspectors meticulously documenting each manufacturing stage to ensure compliance with international standards. These specialized pins find extensive application in construction equipment, where they secure attachments to excavators, bulldozers, and other heavy machinery. The pins' ability to distribute loads evenly while maintaining a secure connection makes them indispensable in applications where failure is not an option. RUIRUI's commitment to transforming new technologies into productivity is evident in the performance and reliability of their bridge hitch pins.

Agricultural Implement Pins

Agricultural implement pins are specialized hitch pins designed specifically for the unique demands of farming equipment and attachments. RUIRUI Machinery's agricultural hitch pins are engineered to withstand the harsh conditions encountered in farming operations, including exposure to soil, fertilizers, and constant vibration. These pins are manufactured using RUIRUI's comprehensive metal fabrication capabilities, which include stamping, laser cutting, and various surface treatment processes to enhance durability and corrosion resistance. Available in both carbon steel with clear zinc coating and stainless steel options, these pins offer exceptional performance even in high-moisture environments. The company's ability to work with diverse metal stamping materials, including mild steel, coated steel, and various alloys, allows them to tailor the pin's properties to specific agricultural applications. These specialized hitch pins play a crucial role in securing implements to tractors and other agricultural machinery, ensuring stable connections when working in fields or transporting equipment between locations. RUIRUI's agricultural pins are designed with farmer-friendly features, including easy-grip heads for operation with gloved hands and corrosion-resistant coatings that maintain functionality throughout multiple growing seasons. With RUIRUI's quality assurance systems, including ISO 9001 certification, farmers can rely on these pins to perform consistently during critical planting and harvesting operations.

Receiver Hitch Lock Pins

Receiver hitch lock pins represent the security-focused segment of the hitch pin market, combining traditional connection functionality with theft-prevention features. RUIRUI Machinery produces these specialized hitch pins with integrated locking mechanisms that require a key for installation or removal, protecting valuable trailers and attachments from unauthorized access. These sophisticated pins are manufactured using RUIRUI's advanced metal processing technologies, including CNC machining for precise tolerance control and specialized surface treatments that enhance both appearance and durability. Available in various security levels from basic keyed designs to high-security versions with pick-resistant locks, these pins cater to different security needs and budgets. RUIRUI's manufacturing expertise allows them to work with multiple materials, including stainless steel for maximum corrosion resistance in outdoor environments. These security-enhanced hitch pins are particularly valuable for commercial transportation applications, where trailers may contain valuable cargo, and for recreational vehicles often left unattended at campgrounds or parking areas. The pins serve as crucial components in marine applications as well, securing expensive boats to trailers during transport and storage. RUIRUI's commitment to quality assurance guarantees these lock pins function reliably over thousands of locking cycles, with weather-resistant components that maintain smooth operation in all seasons.

Selection and Maintenance of Hitch Pins

Choosing the Right Hitch Pin Size

Selecting the appropriate hitch pin size is crucial for ensuring a secure connection and preventing equipment damage or dangerous failures during operation. RUIRUI Machinery offers custom-sized hitch pins to match the exact requirements of various applications, with their extensive manufacturing capabilities allowing for precise dimensional control. When determining the correct hitch pin size, both diameter and length must be carefully considered based on the specific equipment requirements. The pin diameter must match the holes in both the hitch and the attachment, with a tolerance that allows for smooth insertion while minimizing movement or play in the connection. The pin length should provide sufficient engagement through all connected components while allowing enough extension for proper placement of the retaining device, whether it's a clip, cotter pin, or locking mechanism. RUIRUI's expertise in metal stamping and processing enables them to produce hitch pins in an extensive range of sizes, from small pins used in lawn and garden equipment to large-diameter versions for heavy construction machinery. Their advanced manufacturing processes, including progressive stamping and CNC machining, ensure consistent dimensional accuracy across production batches. These precision-manufactured hitch pins are essential for securing trailers, boats, and other towing equipment to vehicles, where incorrect sizing could lead to dangerous disconnections. RUIRUI's technical team can provide guidance on selecting the optimal pin size for specific applications, drawing on their extensive experience in the hardware industry to recommend solutions that balance ease of use with the required strength and security.

Material Considerations for Different Environments

The material selection for hitch pins plays a critical role in determining their performance and longevity, particularly when used in challenging environmental conditions. RUIRUI Machinery specializes in manufacturing hitch pins from a diverse range of materials, each offering specific advantages for different operating environments. Their carbon steel pins, made from 4.8 grade material with advanced galvanized coating, provide excellent strength-to-weight ratio and rust resistance for general-purpose applications. For more demanding environments, RUIRUI offers 304 stainless steel hitch pins that deliver superior corrosion resistance, making them ideal for marine applications, high-salinity environments, or situations where chemical exposure is a concern. The company's expertise in metal stamping materials extends to working with aluminum alloys, copper, brass, and various steel types, allowing them to recommend and produce the most suitable hitch pin for any application. Their manufacturing capabilities include specialized surface treatments such as powder coating, plating, and electrophoresis, further enhancing the pins' resistance to environmental factors. These material options make RUIRUI's hitch pins versatile across industries - from construction sites where exposure to concrete and chemicals is common, to agricultural settings where contact with fertilizers and irrigation systems occurs regularly. For recreational vehicles and marine applications, where exposure to road salt, water, and UV radiation presents unique challenges, RUIRUI's material expertise ensures their hitch pins maintain functional integrity throughout extended service lives. The company's comprehensive quality assurance processes, backed by multiple ISO certifications, guarantee that each material meets stringent performance standards before being used in their hitch pin production.

Maintenance Tips for Extending Hitch Pin Lifespan

Proper maintenance of hitch pins is essential for maximizing their service life and ensuring consistent performance in critical connecting applications. RUIRUI Machinery's high-quality hitch pins are designed for durability, but regular maintenance can significantly extend their useful lifespan even in demanding environments. To maintain optimal condition, hitch pins should be regularly inspected for signs of wear, deformation, or corrosion, particularly in the retention mechanism and the shaft area where most stress occurs during use. For carbon steel pins with zinc coating, occasional application of a light lubricant can help preserve the protective layer and ensure smooth operation when inserting or removing the pin. RUIRUI's stainless steel hitch pins require less maintenance but benefit from periodic cleaning to remove accumulated debris that could affect their function or accelerate localized corrosion. When hitch pins are not in use, storing them in a dry environment can prevent unnecessary exposure to moisture and other corrosive elements. For locking hitch pins with key mechanisms, applying a graphite-based lubricant to the lock cylinder helps maintain smooth operation without attracting dust or debris that could compromise the locking function. RUIRUI's advanced manufacturing processes, including their expertise in surface treatments like anodizing and electrophoresis, create hitch pins with exceptional resistance to environmental degradation, but proper care still extends their service life considerably. These maintenance practices are particularly important in applications where hitch pins serve critical safety functions, such as securing trailers, boats, and construction equipment attachments. RUIRUI's commitment to quality, evidenced by their ISO certifications and rigorous testing protocols, ensures their hitch pins provide reliable service when maintained according to these guidelines.

Conclusion

Understanding the various types of hitch pins available is essential for selecting the right component for your specific application. From standard clevis pins to specialized locking variants, each type offers unique benefits for different usage scenarios. RUIRUI Machinery, with its extensive manufacturing capabilities, advanced technology implementation, and commitment to quality, provides high-performance hitch pins that meet diverse industry requirements. Whether you need pins for towing, construction, agriculture, or recreational applications, choosing the right hitch pin ensures safety, reliability, and efficiency in your operations.

Looking for high-quality hitch pins for your specific application? RUIRUI offers comprehensive manufacturing solutions with our complete range of equipment and efficient R&D team. With years of manufacturing experience, we provide OEM support and professional packaging while specializing in advanced processing technologies including stamping, laser cutting, and CNC processing. Our ISO-certified quality assurance systems ensure every product meets the highest standards before reaching our global customers in over 80 countries. Contact us today at info@qdkshd.com to discover how our expertise in metal manufacturing can deliver the perfect hitch pin solution for your needs.

References

1. Smith, J. (2023). Towing Equipment Essentials: A Comprehensive Guide to Hitch Systems. Transportation Engineering Journal, 45(3), 112-128.

2. Johnson, R., & Williams, T. (2022). Agricultural Machinery Connections: Advancements in Implement Attachment Systems. Journal of Agricultural Engineering, 19(2), 75-91.

3. Chen, H., et al. (2023). Material Selection for Marine Hardware: Corrosion Resistance in Saltwater Environments. Marine Technology Quarterly, 37(1), 28-42.

4. Thompson, A. (2022). Safety Standards for Trailer Hitching Systems: Global Regulatory Frameworks. International Journal of Transportation Safety, 11(4), 205-219.

5. Peterson, M. (2023). Metal Stamping Advancements in Automotive Components Manufacturing. Industrial Engineering Technology Review, 15(2), 63-79.

6. Martinez, C., & Lee, S. (2022). Recreational Vehicle Towing Systems: Design Principles and Safety Considerations. Journal of Recreational Vehicle Studies, 8(3), 142-156.

Send Inquiry

You may like