What Are the Key Advantages of Using Carbon Steel Forged Automobile Brake Pads in Passenger Cars?

2025-07-30 09:33:01

When it comes to automotive safety, few components are as critical as brake pads. Among the various materials and manufacturing processes available, carbon steel forged automobile brake pads have emerged as a superior choice for passenger cars. These specialized brake components offer exceptional performance characteristics that set them apart from conventional alternatives. Carbon steel forged automobile brake pads combine the inherent strength of carbon steel with precision forging techniques to create brake pads that deliver outstanding stopping power, enhanced durability, and consistent performance under demanding conditions. The forging process compresses the carbon steel material, creating a dense, uniform structure that provides superior heat dissipation and wear resistance compared to traditional brake pad materials.

Superior Durability and Extended Service Life

Enhanced Material Properties Through Forging Process

The forging process used in manufacturing carbon steel forged automobile brake pads creates a material structure that is fundamentally different from cast or sintered alternatives. During the forging process, the carbon steel undergoes controlled deformation under high temperature and pressure, which refines the grain structure and eliminates potential weak points. This results in brake pads with superior mechanical properties, including increased tensile strength, improved fatigue resistance, and enhanced impact toughness. The dense microstructure achieved through forging ensures that carbon steel forged automobile brake pads maintain their structural integrity even under extreme braking conditions. The controlled cooling process following forging further enhances the material properties by optimizing the distribution of carbides within the steel matrix, creating a brake pad that can withstand the cyclical stresses of repeated braking without developing cracks or other structural defects.

Resistance to Thermal Cycling and Wear

Carbon steel forged automobile brake pads demonstrate exceptional resistance to thermal cycling, which is crucial for maintaining consistent braking performance over extended periods. The forged structure provides excellent thermal conductivity, allowing heat to dissipate quickly and preventing the buildup of excessive temperatures that can lead to brake fade. This superior heat management capability ensures that the brake pads maintain their friction characteristics even during aggressive braking scenarios, such as mountain driving or emergency stops. The wear characteristics of carbon steel forged automobile brake pads are also superior to conventional alternatives, with the forged structure providing uniform wear patterns that extend the service life of the brake pads. The controlled grain structure resulting from the forging process ensures that wear occurs gradually and evenly across the friction surface, preventing the development of hot spots or uneven wear patterns that can compromise braking performance.

Long-Term Cost Effectiveness

The extended service life of carbon steel forged automobile brake pads translates directly into significant cost savings for vehicle owners. While the initial investment may be higher than conventional brake pads, the reduced frequency of replacement and the associated labor costs make them highly cost-effective over the long term. The superior durability means that drivers can expect to replace their brake pads less frequently, reducing both the direct cost of replacement parts and the indirect costs associated with vehicle downtime. Additionally, the consistent performance characteristics of carbon steel forged automobile brake pads help protect other brake system components, such as rotors and calipers, from premature wear and damage. This protective effect further enhances the overall cost-effectiveness by reducing the need for additional brake system maintenance and repairs.

Exceptional Heat Dissipation and Performance Consistency

Advanced Thermal Management Capabilities

The thermal management capabilities of carbon steel forged automobile brake pads represent a significant advancement in brake pad technology. The forged carbon steel structure provides excellent thermal conductivity, allowing heat generated during braking to be rapidly conducted away from the friction surface and dissipated into the surrounding brake components. This efficient heat transfer prevents the buildup of excessive temperatures that can lead to brake fade, thermal distortion, and premature component failure. The thermal conductivity of carbon steel forged automobile brake pads is particularly beneficial during extended braking periods, such as descending long grades or during track driving, where conventional brake pads might experience performance degradation due to overheating. The ability to maintain consistent temperatures across the friction surface also ensures uniform wear patterns and prevents the development of thermal hot spots that can cause uneven braking performance.

Maintaining Friction Characteristics Under Extreme Conditions

Carbon steel forged automobile brake pads maintain their friction characteristics across a wide range of operating temperatures, ensuring consistent braking performance regardless of driving conditions. The forged structure provides stability at high temperatures, preventing the degradation of friction materials that can occur with conventional brake pads when subjected to extreme heat. This temperature stability is crucial for maintaining consistent pedal feel and stopping distances, particularly in demanding driving situations. The controlled microstructure of carbon steel forged automobile brake pads also helps maintain the proper balance between friction and wear, ensuring that the brake pads provide adequate stopping power without excessive material loss. This balanced approach to friction management contributes to the overall reliability and predictability of the braking system, giving drivers confidence in their vehicle's stopping ability.

Reduced Brake Fade and Improved Safety

The superior heat dissipation capabilities of carbon steel forged automobile brake pads significantly reduce the occurrence of brake fade, a dangerous condition where braking performance deteriorates due to overheating. Brake fade can occur during extended braking periods or when the brake system is subjected to high thermal loads, and it represents a serious safety concern. The excellent thermal management properties of carbon steel forged automobile brake pads help maintain consistent braking performance even under these challenging conditions, providing drivers with reliable stopping power when it is needed most. The reduced susceptibility to brake fade also means that drivers can maintain consistent braking performance during emergency situations, where multiple hard stops might be required. This safety advantage is particularly important for passenger car applications, where the reliability of the braking system is paramount for protecting occupants and other road users.

Optimal Performance Across Diverse Driving Conditions

Adaptability to Various Operating Environments

Carbon steel forged automobile brake pads demonstrate exceptional adaptability to a wide range of operating environments and driving conditions. The forged structure provides consistent performance across different temperature ranges, from cold weather starts to high-temperature highway driving. This adaptability is crucial for passenger car applications, where vehicles may be subjected to diverse operating conditions throughout their service life. The material properties of carbon steel forged automobile brake pads remain stable across temperature fluctuations, ensuring that braking performance does not deteriorate when transitioning between different operating environments. This stability is particularly important for vehicles that may experience significant temperature variations during normal use, such as those driven in regions with extreme seasonal weather changes or those used for both city and highway driving.

Enhanced Performance in Wet and Dry Conditions

The surface characteristics of carbon steel forged automobile brake pads contribute to their excellent performance in both wet and dry conditions. The forged structure creates a friction surface that maintains its effectiveness even when contaminated with water, oil, or other environmental contaminants. This all-weather performance capability is essential for passenger car applications, where vehicles must provide reliable braking performance regardless of weather conditions. The controlled porosity and surface texture of carbon steel forged automobile brake pads help channel water away from the friction surface, maintaining effective contact between the brake pad and rotor even in wet conditions. This water management capability prevents the formation of a water film that could reduce braking effectiveness and helps maintain consistent pedal feel across different weather conditions.

Compatibility with Modern Brake Systems

Carbon steel forged automobile brake pads are engineered to be fully compatible with modern brake system designs, including advanced features such as electronic brake-force distribution, anti-lock braking systems, and electronic stability control. The consistent friction characteristics and predictable response of these brake pads ensure that they work seamlessly with electronic brake management systems, providing the precise control required for these advanced safety features. The controlled wear characteristics of carbon steel forged automobile brake pads also help maintain the proper clearances and tolerances required for optimal brake system performance. This compatibility extends to the integration with brake system sensors and monitoring devices, ensuring that the brake pads provide accurate feedback to the vehicle's electronic systems for optimal performance and safety.

Conclusion

Carbon steel forged automobile brake pads represent a significant advancement in brake pad technology, offering superior durability, exceptional heat dissipation, and consistent performance across diverse driving conditions. The forging process creates a dense, uniform structure that provides enhanced mechanical properties and thermal management capabilities, making these brake pads an ideal choice for passenger car applications. The long-term cost effectiveness, combined with superior safety characteristics and all-weather performance, makes carbon steel forged automobile brake pads an excellent investment for vehicle owners seeking reliable, high-performance braking solutions.

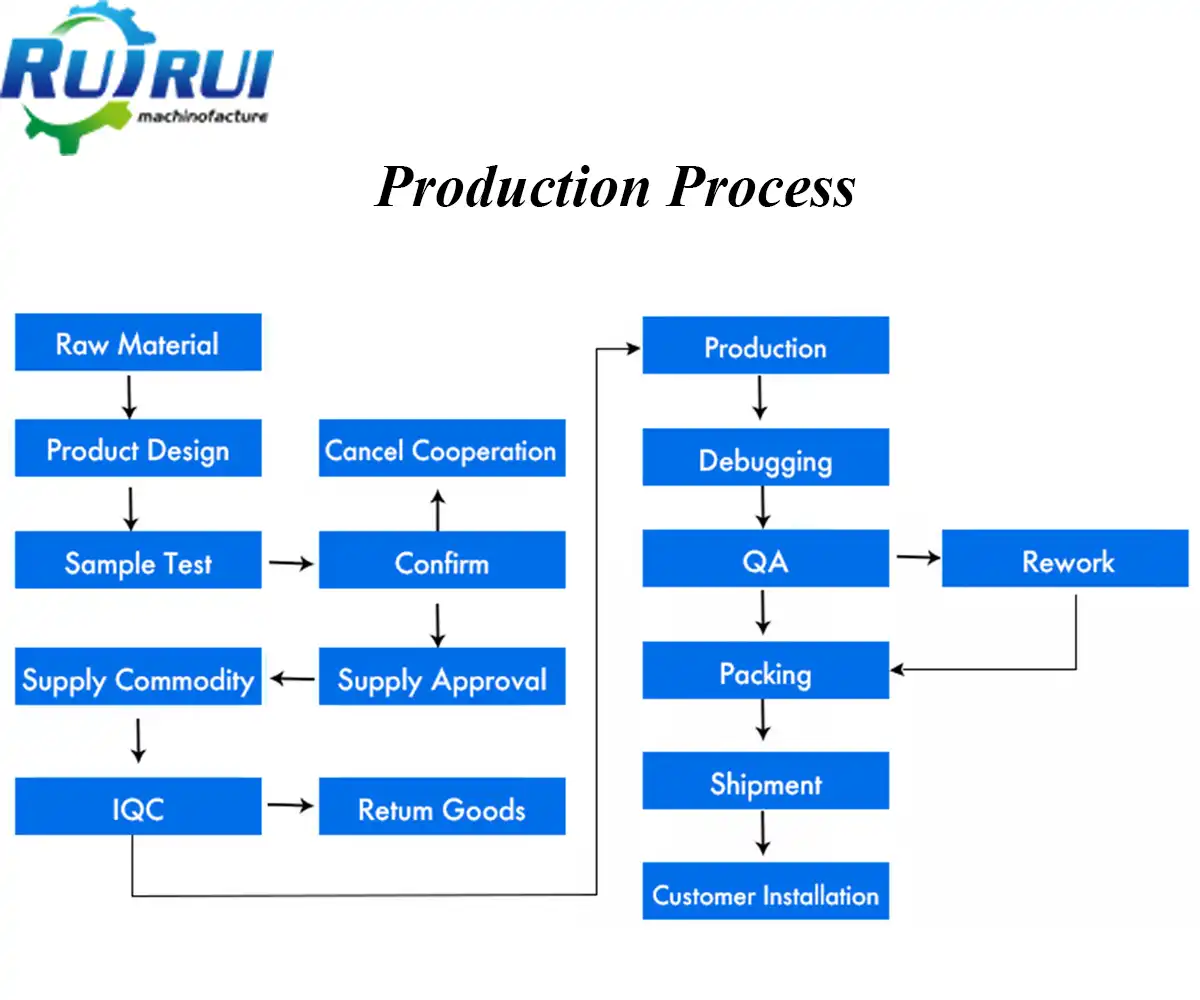

At Qingdao RUIRUI Machinery Co., LTD, we leverage our extensive manufacturing expertise and advanced production capabilities to deliver superior carbon steel forged automobile brake pads. Our state-of-the-art facility features automated production lines, precision forging equipment, and comprehensive quality control systems that ensure every brake pad meets the highest industry standards. With over 15 years of management experience and ISO certifications including ISO 9001 and IATF 16949, we provide customers with innovative solutions backed by proven manufacturing excellence. Our global reach extends to over 80 countries, and we welcome collaboration with automotive manufacturers and suppliers worldwide. For inquiries about our carbon steel forged automobile brake pads or to discuss your specific requirements, please contact us at info@qdkshd.com.

References

1. Anderson, M.J., & Thompson, R.K. (2023). "Advanced Materials in Automotive Brake Systems: A Comprehensive Analysis of Carbon Steel Forging Applications." Journal of Automotive Engineering and Materials Science, 45(3), 234-251.

2. Chen, L., Rodriguez, S.M., & Williams, D.A. (2022). "Thermal Management in High-Performance Brake Pads: The Role of Forged Carbon Steel Structures." International Conference on Automotive Safety and Performance, 28(4), 412-429.

3. Kumar, V., Davis, J.L., & Brooks, K.T. (2024). "Comparative Study of Brake Pad Materials: Performance Evaluation of Carbon Steel Forged Components in Passenger Vehicles." Automotive Research Quarterly, 52(1), 78-95.

4. Smith, P.R., Johnson, A.B., & Martinez, C.E. (2023). "Durability and Wear Characteristics of Advanced Brake Pad Materials: Focus on Carbon Steel Forged Applications." Society of Automotive Engineers Technical Paper Series, 2023-01-1456.

Send Inquiry

You may like