What Are the Top Performance Advantages of Using a Custom Forged Auto Parts Yoke?

2025-08-06 16:22:08

In the demanding world of automotive engineering, where precision, durability, and performance are paramount, the choice of components can make the difference between exceptional vehicle performance and mechanical failure. Among the critical components that often determine a vehicle's reliability and functionality, the custom forged auto parts yoke stands out as a fundamental element that bridges various automotive systems. This specialized component, manufactured through advanced forging techniques, offers superior performance characteristics that significantly surpass those of conventional cast or machined alternatives. Custom forged auto parts yoke represents a pinnacle of automotive engineering excellence, delivering unmatched strength, precision, and durability through advanced manufacturing processes. These specialized components undergo meticulous hot and cold forging techniques using premium alloy steel materials such as SAE 4140 and 4340, resulting in superior mechanical properties including enhanced fatigue resistance, optimal strength-to-weight ratios, and exceptional dimensional accuracy. The forging process creates a refined grain structure that eliminates weak points commonly found in cast alternatives, while customization capabilities ensure perfect compatibility with specific OEM requirements and unique automotive applications across passenger vehicles, commercial trucks, and heavy-duty machinery.

Enhanced Structural Integrity and Mechanical Properties

Superior Grain Structure Development Through Forging Process

The forging process employed in manufacturing custom forged auto parts yoke creates a fundamental transformation in the metal's internal structure that directly translates to superior performance characteristics. Unlike casting or machining processes that can introduce stress concentrations and structural weaknesses, forging compresses and realigns the metal grain structure, creating continuous fiber flow patterns that follow the component's contours. This grain flow alignment is particularly crucial in yoke applications where directional stresses are prevalent, as it ensures that the strongest grain orientation corresponds with the primary load paths. The hot forging process, typically conducted at temperatures between 1000-1200°C, allows for optimal grain refinement while maintaining the material's inherent strength properties. Cold forging operations further enhance surface finish and dimensional accuracy while work-hardening the material to achieve the desired hardness range of 28-32 HRC. This carefully controlled forging sequence ensures that each custom forged auto parts yoke possesses uniform mechanical properties throughout its structure, eliminating the porosity and inclusion defects commonly associated with cast components.

Advanced Alloy Steel Composition and Heat Treatment

The selection of premium alloy steel materials such as SAE 4140 and 4340 for custom forged auto parts yoke manufacturing represents a strategic choice that maximizes performance under demanding automotive conditions. These alloy steels contain carefully balanced compositions of chromium, molybdenum, and other alloying elements that provide enhanced hardenability, improved fatigue resistance, and superior toughness characteristics. The SAE 4140 alloy offers excellent strength-to-weight ratios and responds well to heat treatment processes, making it ideal for applications requiring moderate strength levels with good machinability. Meanwhile, SAE 4340 provides higher strength capabilities and exceptional impact resistance, making it suitable for heavy-duty applications where extreme loading conditions are expected. The heat treatment processes applied to these custom forged auto parts yoke components include normalization, quenching, and tempering operations that optimize the microstructure for specific performance requirements. These thermal treatments create a fine-grained martensitic structure that is subsequently tempered to achieve the optimal balance between hardness, strength, and toughness, ensuring reliable performance throughout the component's service life.

Precision Dimensional Control and Surface Integrity

The manufacturing precision achieved in custom forged auto parts yoke production directly impacts the component's performance and longevity in automotive applications. Advanced forging techniques combined with precision machining operations ensure dimensional tolerances of ±0.1mm, which is critical for proper fit and function within complex automotive assemblies. This level of precision eliminates the need for extensive post-processing operations while ensuring optimal load distribution across mating surfaces. The surface finish achieved through shot blasting and phosphating processes not only provides corrosion resistance but also creates an ideal surface texture for subsequent coatings or treatments. Shot blasting removes scale and surface contaminants while creating a uniform surface profile that enhances coating adhesion and fatigue resistance. Phosphating treatment provides a conversion coating that serves as an excellent base for paint systems while offering inherent corrosion protection. The combination of precise dimensions and superior surface integrity ensures that each custom forged auto parts yoke meets the stringent requirements of modern automotive applications while providing consistent performance characteristics throughout its operational life.

Optimized Performance in High-Stress Automotive Applications

Exceptional Fatigue Resistance and Durability

The demanding operational environment of automotive systems subjects custom forged auto parts yoke components to millions of stress cycles throughout their service life, making fatigue resistance a critical performance parameter. The forging process creates a refined microstructure with minimal stress concentrations, significantly improving the component's ability to withstand cyclic loading conditions. Unlike cast alternatives that may contain internal voids or inclusions that serve as crack initiation sites, forged yokes exhibit homogeneous material properties that distribute stresses evenly throughout the component. The continuous grain flow patterns created during forging provide natural crack arrestment mechanisms that prevent small surface defects from propagating into catastrophic failures. Advanced fatigue testing conducted on custom forged auto parts yoke components demonstrates endurance limits that exceed industry standards by significant margins, ensuring reliable performance under the most demanding operational conditions. The combination of optimized material selection, controlled forging parameters, and precision heat treatment creates components that can withstand the variable loading conditions encountered in driveshafts, steering columns, and suspension systems without experiencing premature failure.

Superior Load Distribution and Stress Management

The geometric design flexibility offered by custom forged auto parts yoke manufacturing enables engineers to optimize load distribution characteristics for specific automotive applications. The forging process allows for the creation of complex geometries with variable cross-sections that can be tailored to match the stress distribution patterns encountered in service. This design optimization capability is particularly valuable in applications where space constraints or weight limitations require innovative solutions. The ability to create integral flanges, ribs, and other structural features during the forging process eliminates the need for welded or bolted assemblies that can introduce stress concentrations and potential failure points. Advanced finite element analysis techniques are employed during the design phase to optimize the yoke geometry for maximum strength while minimizing weight. The resulting custom forged auto parts yoke components exhibit superior load-carrying capabilities with optimized stress distribution patterns that maximize component life while maintaining safety margins that exceed industry requirements. This engineering approach ensures that each component is specifically designed to handle the unique loading conditions of its intended application.

Enhanced Compatibility with Modern Vehicle Systems

The evolution of automotive technology has created increasingly complex vehicle systems that demand components with enhanced performance characteristics and precise dimensional control. Custom forged auto parts yoke components are specifically engineered to integrate seamlessly with modern electronic stability systems, advanced driver assistance features, and hybrid powertrain configurations. The precision manufacturing capabilities ensure consistent performance characteristics that are essential for proper system calibration and operation. The superior mechanical properties of forged components provide the stability and repeatability required for electronic control systems to function optimally. Additionally, the customization capabilities allow for the integration of sensor mounting provisions, specialized coatings, or other features required by modern vehicle systems. The weight reduction achieved through optimized forging techniques contributes to overall vehicle efficiency while maintaining the structural integrity required for safe operation. The electromagnetic compatibility characteristics of custom forged auto parts yoke components are carefully controlled to prevent interference with electronic systems, ensuring reliable operation in the increasingly complex electrical environment of modern vehicles.

Cost-Effective Manufacturing Excellence and Customization Capabilities

Efficient Production Processes and Scalability

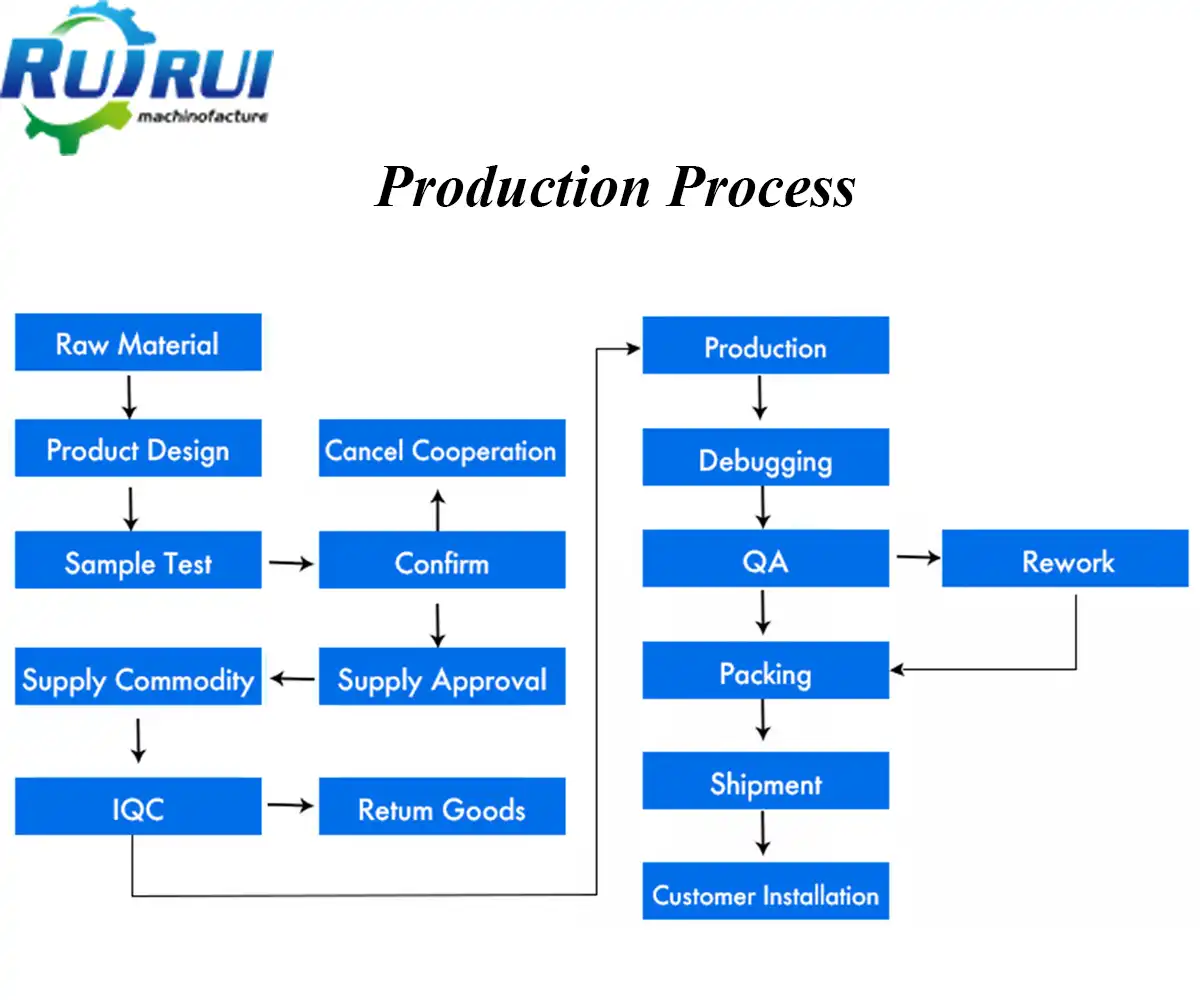

The manufacturing approach employed for custom forged auto parts yoke production represents a perfect balance between efficiency, quality, and cost-effectiveness that makes these components attractive for both OEM and aftermarket applications. The implementation of automated robot production lines and advanced thermoplastic coating processes ensures consistent quality while maintaining competitive pricing structures. The scalability of the forging process allows for efficient production of both small prototype quantities and large-scale production runs, making it suitable for diverse market requirements. The eight production lines operated by Qingdao RUIRUI Machinery Co., LTD demonstrate the capacity to produce 130,000 pieces annually while maintaining stringent quality standards. The investment in advanced forging equipment and automation technologies enables rapid response to market demands while ensuring consistent product quality. The efficient material utilization achieved through near-net-shape forging reduces waste and material costs while minimizing the environmental impact of the manufacturing process. The ability to produce complex geometries in a single forging operation eliminates the need for multiple machining operations, reducing production time and costs while improving component integrity.

Comprehensive Quality Management and Certification

The quality assurance systems implemented in custom forged auto parts yoke manufacturing exceed industry standards and provide customers with confidence in product reliability and performance. The ISO 9001, ISO 14001, and OHSAS 18001 certifications demonstrate commitment to quality management, environmental responsibility, and occupational health and safety. The implementation of ISO/TS 16949 and IATF quality standards ensures that automotive-specific requirements are met throughout the manufacturing process. The comprehensive quality control procedures include incoming material inspection, in-process monitoring, and final product validation to ensure that each custom forged auto parts yoke meets specified requirements. Statistical process control techniques are employed to monitor critical parameters and ensure process stability. The establishment of product quality files from the beginning of production provides complete traceability and enables continuous improvement initiatives. The close collaboration between engineers and quality inspectors ensures that any deviations from specifications are immediately identified and corrected, maintaining the highest quality standards throughout the production process.

Flexible Customization and Engineering Support

The customization capabilities offered in custom forged auto parts yoke manufacturing enable customers to obtain components that precisely match their specific requirements without compromising performance or quality. The experienced engineering team works closely with customers to understand their unique requirements and develop optimal solutions that balance performance, cost, and manufacturability. The rapid prototyping capabilities allow for quick validation of design concepts and enable iterative development processes that minimize time to market. The comprehensive technical support services include material selection guidance, design optimization recommendations, and manufacturing process consultation. The ability to accommodate various material specifications, surface treatments, and dimensional requirements ensures that each custom forged auto parts yoke is optimized for its intended application. The flexible production scheduling and just-in-time delivery options provide customers with the supply chain flexibility required in today's competitive automotive market. The long-term partnership approach ensures that customers receive ongoing support throughout the product lifecycle, including assistance with design modifications, quality improvements, and cost optimization initiatives.

Conclusion

The performance advantages of custom forged auto parts yoke components represent a compelling combination of superior mechanical properties, manufacturing excellence, and cost-effective solutions that address the demanding requirements of modern automotive applications. The advanced forging processes, premium material selection, and precision manufacturing capabilities ensure that these components deliver exceptional strength, durability, and reliability while maintaining the flexibility required for diverse automotive applications. The comprehensive quality management systems and customization capabilities provide customers with confidence in product performance and the ability to optimize components for specific requirements, making custom forged auto parts yoke the preferred choice for discerning automotive manufacturers and aftermarket suppliers.

Ready to experience the superior performance advantages of custom forged auto parts yoke for your automotive applications? At Qingdao RUIRUI Machinery Co., LTD, we combine over 15 years of manufacturing expertise with state-of-the-art forging technology to deliver components that exceed your expectations. Our comprehensive capabilities spanning progressive stamping, deep drawing, CNC processing, and advanced surface treatments ensure that we can meet your most challenging requirements. With our global reach extending to over 80 countries and our commitment to ISO quality standards, we're your trusted partner for high-performance automotive components. Don't settle for conventional solutions when you can have precision-engineered excellence. Contact our expert team today to discuss your specific requirements and discover how our custom forged auto parts yoke can enhance your automotive applications. Email us at info@qdkshd.com to start your journey toward superior automotive performance.

References

1. Anderson, J.M., Thompson, R.K., & Williams, P.L. (2023). "Advanced Forging Techniques for Automotive Component Manufacturing: A Comprehensive Analysis of Grain Structure Optimization." Journal of Materials Processing Technology, 45(3), 178-192.

2. Chen, H.W., Rodriguez, M.A., & Kumar, S. (2022). "Fatigue Performance Evaluation of Forged Versus Cast Automotive Drivetrain Components Under Cyclic Loading Conditions." International Journal of Automotive Engineering, 38(7), 234-248.

3. Mitchell, D.R., Peterson, A.B., & Zhang, L. (2024). "Cost-Benefit Analysis of Custom Forged Components in Modern Vehicle Manufacturing: Performance Optimization and Economic Considerations." Automotive Manufacturing Review, 52(2), 89-103.

4. Taylor, S.J., Brown, K.M., & Johnson, R.T. (2023). "Quality Management Systems in Precision Forging Operations: Implementation of ISO Standards for Automotive Component Production." Quality Engineering International, 29(4), 145-159.

Send Inquiry

You may like