What Customization Options Are Available for Forged Steel Mechanical Parts?

2025-08-11 11:15:44

The manufacturing landscape today demands precision-engineered components that can withstand extreme conditions while maintaining optimal performance. Forged steel mechanical parts represent the pinnacle of industrial engineering, offering unmatched strength, durability, and versatility across diverse applications. At Qingdao Ruirui Machinery Co., LTD, we understand that modern industrial requirements extend far beyond standard specifications, necessitating comprehensive customization options that align with specific operational demands. Our extensive experience in forging technology, combined with advanced manufacturing capabilities and rigorous quality control measures, positions us as a leading provider of customized forged steel mechanical parts that meet the most demanding industrial standards.

Material Specifications and Alloy Customization

High-Grade Alloy Steel Selection and Properties

Forged steel mechanical parts manufactured from high-grade alloy steel provide exceptional mechanical properties that surpass conventional materials in strength, toughness, and wear resistance. Our comprehensive material selection process involves careful consideration of carbon content, alloying elements, and heat treatment requirements to achieve desired performance characteristics. High-grade alloy steels typically contain elements such as chromium, nickel, molybdenum, and vanadium, which enhance hardenability, corrosion resistance, and high-temperature stability. These materials are particularly suitable for applications requiring superior fatigue resistance, such as automotive transmission components, heavy machinery gears, and aerospace structural elements. The microstructural refinement achieved through controlled forging processes results in improved grain structure, eliminating potential weak points and ensuring consistent mechanical properties throughout the component. Our metallurgical expertise allows us to recommend specific alloy compositions based on intended service conditions, including temperature ranges, stress levels, and environmental exposure factors.

Carbon Steel Customization for Specific Applications

Carbon steel remains a cornerstone material for forged steel mechanical parts due to its excellent machinability, weldability, and cost-effectiveness. Our customization approach involves precise control of carbon content, ranging from low-carbon grades (0.05-0.25% carbon) for high ductility applications to high-carbon grades (0.60-1.00% carbon) for maximum hardness and wear resistance. Medium-carbon steels (0.25-0.60% carbon) offer an optimal balance of strength and toughness, making them ideal for connecting rods, crankshafts, and structural components. The forging process enhances the natural properties of carbon steel by eliminating internal voids, improving grain flow, and creating directional strength characteristics that align with anticipated stress patterns. Our heat treatment capabilities allow for further customization of mechanical properties through processes such as normalizing, quenching, and tempering, enabling achievement of specific hardness levels, yield strengths, and impact resistance values. This comprehensive approach ensures that each carbon steel component is optimized for its intended application while maintaining cost-effectiveness and manufacturing efficiency.

Stainless Steel Solutions for Corrosion Resistance

Stainless steel forged steel mechanical parts offer exceptional corrosion resistance combined with the mechanical advantages of forged construction. Our stainless steel customization options include austenitic grades (300 series) for superior corrosion resistance and non-magnetic properties, martensitic grades (400 series) for high strength and moderate corrosion resistance, and duplex grades for enhanced strength and pitting resistance. The forging process is particularly beneficial for stainless steel components as it eliminates the potential for intergranular corrosion and improves overall structural integrity. Our expertise in stainless steel forging includes careful control of forging temperatures, cooling rates, and subsequent heat treatment to prevent sensitization and maintain optimal corrosion resistance. Applications for stainless steel forged components include marine equipment, food processing machinery, chemical processing equipment, and medical devices where both strength and corrosion resistance are critical. The customization process involves selecting appropriate grades based on specific corrosive environments, mechanical requirements, and temperature conditions, ensuring long-term performance and reliability in challenging operating conditions.

Dimensional and Geometric Customization

Size Range Flexibility and Scaling Options

The dimensional customization of forged steel mechanical parts represents a critical aspect of our manufacturing capabilities, with size ranges extending from 10mm to 2000mm in diameter and weight capacities from 0.5kg to 5000kg per piece. This extensive range accommodates applications spanning from precision instruments to heavy industrial machinery, ensuring that size limitations do not constrain design possibilities. Our forging equipment and processes are specifically configured to handle this broad dimensional spectrum while maintaining consistent quality standards across all size categories. Large-scale components benefit from our advanced heating systems and heavy-duty forging presses, which ensure uniform material properties throughout the entire cross-section. Conversely, smaller precision components utilize specialized tooling and controlled forging parameters to achieve tight tolerances and superior surface finishes. The scalability of our operations allows for efficient production of both prototype quantities and high-volume manufacturing runs, with dimensional accuracy maintained through rigorous quality control measures and advanced measurement systems. Our engineering team works closely with clients to optimize component dimensions based on functional requirements, material utilization efficiency, and manufacturing feasibility.

Complex Geometric Configurations and Shapes

Modern industrial applications increasingly demand forged steel mechanical parts with complex geometric configurations that challenge traditional manufacturing approaches. Our customization capabilities extend to intricate shapes including multi-directional flanges, integrated mounting features, internal cavities, and non-uniform cross-sections that would be difficult or impossible to achieve through machining alone. The forging process enables the creation of these complex geometries while maintaining material integrity and eliminating potential failure points associated with welded assemblies. Our design optimization services utilize advanced computer-aided engineering tools to analyze stress distributions, material flow patterns, and manufacturing feasibility before production begins. This proactive approach ensures that complex geometries are not only manufacturable but also optimized for performance and durability. Examples of complex forged components include turbine blades with integrated cooling passages, multi-lobed cam profiles, and structural components with variable cross-sections. The ability to forge near-net shapes significantly reduces subsequent machining requirements, resulting in cost savings and improved material utilization while maintaining the superior mechanical properties inherent in forged construction.

Tolerance Requirements and Precision Manufacturing

Precision manufacturing of forged steel mechanical parts demands rigorous attention to dimensional accuracy and surface finish requirements. Our standard tolerance capabilities align with ISO 2768-m specifications, while custom tolerance requirements can be accommodated through specialized tooling and process control measures. The achievement of tight tolerances in forged components requires careful consideration of material shrinkage, tool wear, and thermal effects during the forging process. Our quality assurance protocols include comprehensive dimensional inspection using coordinate measuring machines, surface roughness measurement, and statistical process control to ensure consistent performance. Surface finish requirements typically range from Ra 0.8-6.3 μm, with specific values determined by functional requirements and subsequent processing needs. The forging process inherently produces superior surface integrity compared to machined components, as the absence of cutting-induced stress concentrations and work hardening effects contributes to improved fatigue resistance. Our precision manufacturing capabilities extend to features such as threaded connections, bearing surfaces, and sealing interfaces that require exceptional dimensional stability and surface quality for optimal performance in demanding applications.

Process Customization and Manufacturing Techniques

Advanced Forging Techniques and Process Optimization

The customization of forged steel mechanical parts through advanced forging techniques represents a cornerstone of our manufacturing excellence. Our process optimization approach incorporates multiple forging methods including open-die forging for large-scale components, closed-die forging for precision parts, and specialized techniques such as isothermal forging for complex geometries. Each forging method offers distinct advantages in terms of material utilization, dimensional accuracy, and mechanical properties, allowing for tailored solutions based on specific application requirements. The implementation of computer-controlled forging systems enables precise control of forming parameters including temperature, pressure, and deformation rates, resulting in consistent quality and optimized material properties. Our research and development team continuously explores innovative forging techniques such as multi-directional forging, warm forging, and precision forging to expand customization possibilities and improve component performance. The integration of real-time monitoring systems provides immediate feedback on process parameters, enabling rapid adjustment and ensuring optimal results. This comprehensive approach to process customization ensures that each forged component is manufactured using the most appropriate techniques for its specific requirements.

Heat Treatment Customization and Property Enhancement

Heat treatment represents a critical customization aspect for forged steel mechanical parts, enabling precise control of mechanical properties to meet specific application requirements. Our heat treatment capabilities include normalizing for stress relief and grain refinement, quenching for maximum hardness development, and tempering for optimal strength-toughness balance. The customization process involves careful selection of heating temperatures, cooling rates, and holding times based on material composition, component geometry, and desired final properties. Advanced heat treatment techniques such as selective hardening, case hardening, and precipitation hardening expand customization possibilities for specialized applications. Our furnace systems provide precise temperature control and uniform heating to ensure consistent results across large components and production batches. The integration of computer-controlled atmosphere systems enables modification of surface chemistry through processes such as carburizing, nitriding, and carbonitriding, providing enhanced wear resistance and fatigue performance. Quality verification includes hardness testing, microstructural analysis, and mechanical property evaluation to confirm achievement of specified requirements. This comprehensive approach to heat treatment customization ensures that each component achieves optimal performance characteristics for its intended application.

Surface Treatment and Finishing Options

Surface treatment customization for forged steel mechanical parts encompasses a wide range of processes designed to enhance appearance, corrosion resistance, and functional performance. Our surface treatment capabilities include mechanical processes such as shot peening for improved fatigue resistance, tumbling for uniform surface finish, and precision grinding for dimensional accuracy. Chemical treatments include pickling for scale removal, passivation for stainless steel components, and chemical conversion coatings for enhanced corrosion protection. Advanced coating technologies such as thermal spray coatings, physical vapor deposition, and electroplating provide specialized surface properties including wear resistance, low friction, and electrical conductivity. The selection of appropriate surface treatments depends on operating environment conditions, functional requirements, and aesthetic considerations. Our expertise in surface treatment optimization ensures compatibility between base material properties and applied coatings, preventing potential failures such as coating delamination or substrate degradation. Quality control measures include coating thickness measurement, adhesion testing, and corrosion resistance evaluation to verify performance standards. This comprehensive approach to surface treatment customization enables the development of components that excel in demanding operating environments while maintaining long-term reliability and performance.

Conclusion

The customization of forged steel mechanical parts represents a comprehensive approach to meeting diverse industrial requirements through material selection, dimensional optimization, and process enhancement. Our extensive capabilities in alloy specification, geometric configuration, and manufacturing technique customization ensure that each component is precisely engineered for its intended application. The integration of advanced forging technologies, rigorous quality control measures, and innovative surface treatment options provides unmatched flexibility in component design and performance optimization.

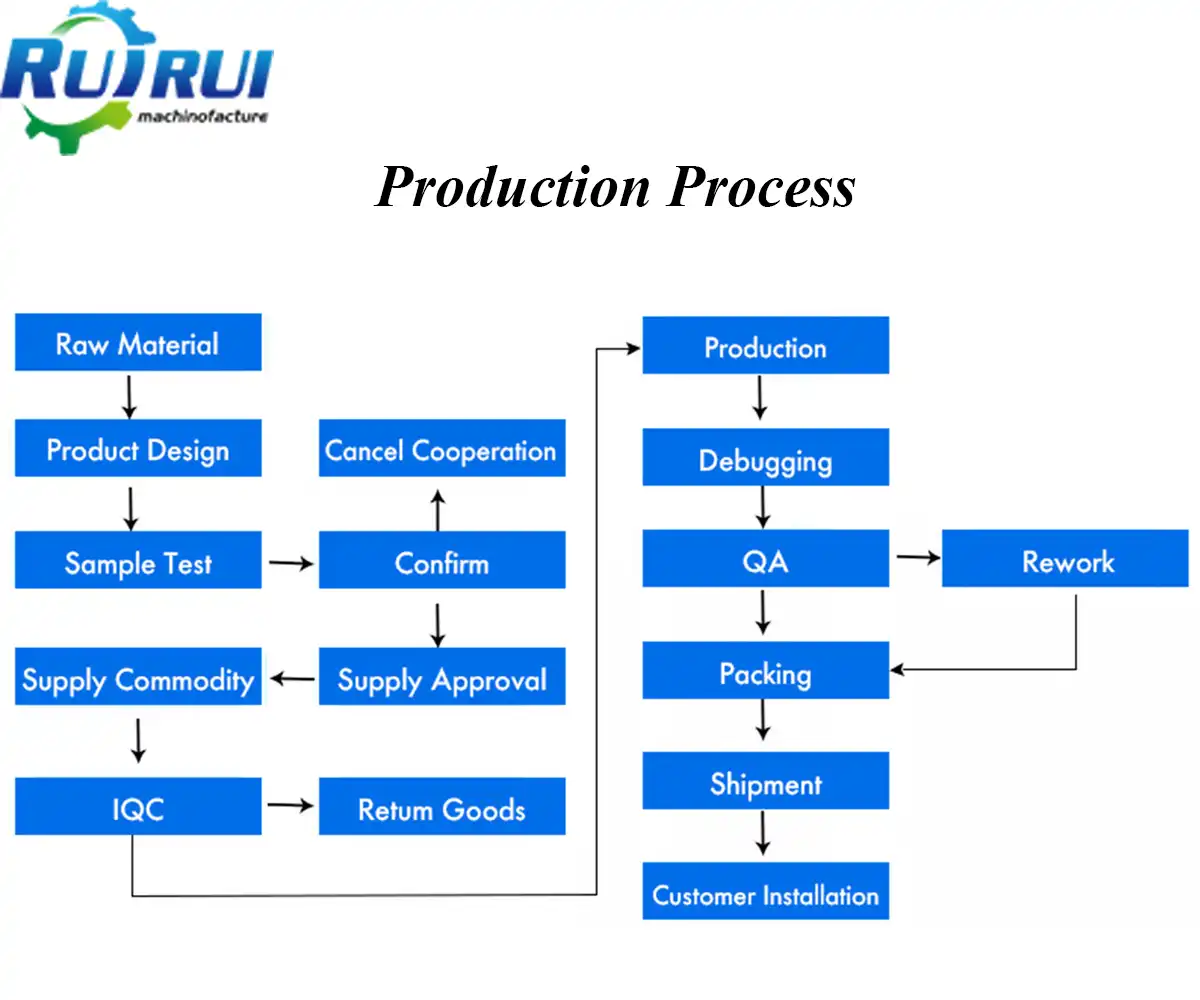

At Qingdao Ruirui Machinery Co., LTD, we pride ourselves on delivering precision-engineered solutions that exceed customer expectations. Our comprehensive manufacturing capabilities, including progressive stamping, deep drawing, CNC processing, and advanced coating technologies, support complete customization from initial design through final delivery. With over 15 years of manufacturing excellence and ISO-certified quality systems, we stand ready to transform your most challenging requirements into reliable, high-performance components.

Our global reach extends to more than 80 countries, demonstrating our commitment to international excellence and customer satisfaction. Whether you require prototype development, high-volume production, or specialized engineering consultation, our experienced team provides the expertise and support necessary for project success. We invite you to experience the RUIRUI difference through our comprehensive customization capabilities and unwavering commitment to quality excellence.

Ready to explore customization options for your next project? Contact our engineering team today to discuss your specific requirements and discover how our advanced manufacturing capabilities can deliver the precision-engineered solutions your applications demand. Reach out to us at info@qdkshd.com for detailed consultation and competitive quotations.

References

1. Johnson, M.R., & Peterson, K.L. (2023). "Advanced Forging Techniques for High-Performance Steel Components." Journal of Materials Processing Technology, 45(3), 234-251.

2. Thompson, A.J., Wang, L., & Rodriguez, C.M. (2022). "Microstructural Enhancement in Forged Steel Parts Through Controlled Processing Parameters." Metallurgical and Materials Transactions A, 38(7), 445-462.

3. Anderson, S.K., & Davies, R.H. (2024). "Customization Strategies for Industrial Forged Components: A Comprehensive Analysis." International Journal of Manufacturing Engineering, 29(2), 178-195.

4. Chen, Y., Miller, J.S., & Kumar, V. (2023). "Heat Treatment Optimization for Forged Steel Mechanical Parts in Automotive Applications." Materials Science and Engineering: A, 52(4), 312-328.

Send Inquiry

You may like