Why Choose a High-Strength Steel Car Tuning Accessories Towbar for Enhanced Durability?

2025-06-24 10:53:36

When it comes to vehicle modification and towing capabilities, selecting the right car tuning accessories towbar becomes crucial for both performance and safety. High-strength steel towbars represent the pinnacle of engineering excellence in automotive accessories, offering unmatched durability and reliability for demanding applications. These precision-engineered components undergo rigorous manufacturing processes using advanced metallurgy techniques, ensuring they can withstand extreme loads while maintaining structural integrity. The superior material composition of high-strength steel provides exceptional resistance to corrosion, fatigue, and environmental factors that commonly affect standard towbars. With weight capacities reaching up to 3500 kg and customizable dimensions to fit various vehicle models, these towbars deliver professional-grade performance that exceeds industry standards and customer expectations.

Superior Material Engineering and Construction Quality

Advanced High-Strength Steel Composition

The foundation of any exceptional car tuning accessories towbar lies in its material composition and engineering excellence. High-strength steel represents a significant advancement over conventional materials, incorporating specialized alloys that enhance tensile strength, yield resistance, and overall structural integrity. At Qingdao RUIRUI Machinery Co., LTD, our manufacturing process begins with carefully selected raw materials that undergo comprehensive testing to ensure they meet stringent quality standards. The high-strength steel used in our car tuning accessories towbar production features enhanced carbon content and specialized alloying elements that provide superior mechanical properties compared to standard mild steel alternatives. This advanced material composition enables our towbars to handle extreme loading conditions while maintaining dimensional stability and resistance to deformation. Our facility employs state-of-the-art metallurgical processes including controlled cooling, heat treatment, and stress relief procedures that optimize the steel's microstructure for maximum performance. The result is a car tuning accessories towbar that delivers exceptional durability, extended service life, and reliable performance under the most demanding conditions.

Precision Manufacturing and Quality Control

Manufacturing excellence plays a critical role in determining the performance and reliability of any car tuning accessories towbar system. Our production facility utilizes advanced CNC machining centers, laser cutting equipment, and precision welding technologies to ensure every component meets exact specifications and tolerances. The manufacturing process begins with computer-aided design and engineering analysis that optimizes stress distribution and load-bearing characteristics throughout the towbar structure. Progressive stamping and deep drawing techniques are employed to create complex geometries that maximize strength while minimizing weight and material usage. Our skilled technicians utilize specialized welding procedures including TIG and MIG welding processes that create seamless joints with superior strength characteristics. Quality control measures are implemented at every stage of production, with dimensional inspections, material testing, and stress analysis conducted to verify compliance with international standards. Each car tuning accessories towbar undergoes comprehensive testing including load testing, fatigue analysis, and corrosion resistance evaluation before receiving final approval for shipment to customers worldwide.

Surface Treatment and Protective Coatings

The longevity and performance of any car tuning accessories towbar depends significantly on its ability to resist environmental factors and maintain structural integrity over time. Our powder coating process provides exceptional protection against corrosion, UV degradation, and mechanical damage while enhancing the aesthetic appearance of the finished product. The multi-stage surface preparation process includes sonic cleaning, deburring, and chemical etching that creates optimal adhesion conditions for the protective coating system. Our advanced thermoplastic coating processes utilize electrostatic application techniques that ensure uniform coverage and superior adhesion characteristics. The powder coating formulation incorporates specialized additives that provide enhanced weather resistance, impact protection, and chemical compatibility with various automotive fluids and environmental contaminants. Additional surface treatment options including anodizing, plating, and electrophoresis are available for specialized applications requiring enhanced corrosion resistance or specific aesthetic requirements. This comprehensive approach to surface protection ensures that our car tuning accessories towbar maintains its performance characteristics and visual appearance throughout its operational lifetime, providing customers with exceptional value and reliability.

Enhanced Performance Characteristics and Load Capacity

Superior Weight Handling and Towing Capacity

The primary advantage of selecting a high-strength steel car tuning accessories towbar lies in its exceptional load-bearing capabilities and towing performance characteristics. Our engineering team has developed towbar designs that can safely handle loads up to 3500 kg while maintaining structural integrity and dimensional stability under extreme conditions. The high-strength steel construction provides superior yield strength and tensile properties that enable safe operation at maximum rated capacities without risk of deformation or failure. Advanced finite element analysis and computer modeling techniques are utilized during the design phase to optimize stress distribution and identify potential failure points before production begins. The robust construction of our car tuning accessories towbar incorporates reinforced mounting points, strategic material thickness variations, and optimized geometry that maximizes load transfer efficiency while minimizing stress concentrations. Field testing and validation procedures confirm that our towbars consistently exceed their rated capacities with substantial safety margins, providing customers with confidence in their towing operations. The superior performance characteristics make these towbars ideal for commercial applications, recreational vehicle towing, and demanding industrial uses where reliability and safety are paramount considerations.

Improved Vehicle Stability and Handling

Installing a high-quality car tuning accessories towbar significantly enhances vehicle stability and handling characteristics during towing operations. The rigid construction and precise mounting geometry of our towbars provide superior load distribution that minimizes the impact of trailer dynamics on vehicle performance. Advanced engineering analysis ensures that the towbar mounting system integrates seamlessly with the vehicle's structural components, creating a unified system that maintains optimal weight distribution and center of gravity positioning. The high-strength steel construction resists flexing and deformation under load, which eliminates unwanted trailer movement and reduces the risk of jackknifing or instability during emergency maneuvers. Our car tuning accessories towbar design incorporates strategic reinforcement elements that distribute towing loads across multiple vehicle mounting points, reducing stress concentrations and improving overall system reliability. The enhanced stability characteristics provided by our towbars result in improved driver confidence, reduced fatigue during long-distance towing, and enhanced safety for both the towing vehicle and other road users. Professional installation and proper integration with vehicle systems ensure optimal performance and compliance with safety regulations.

Compatibility and Versatility Features

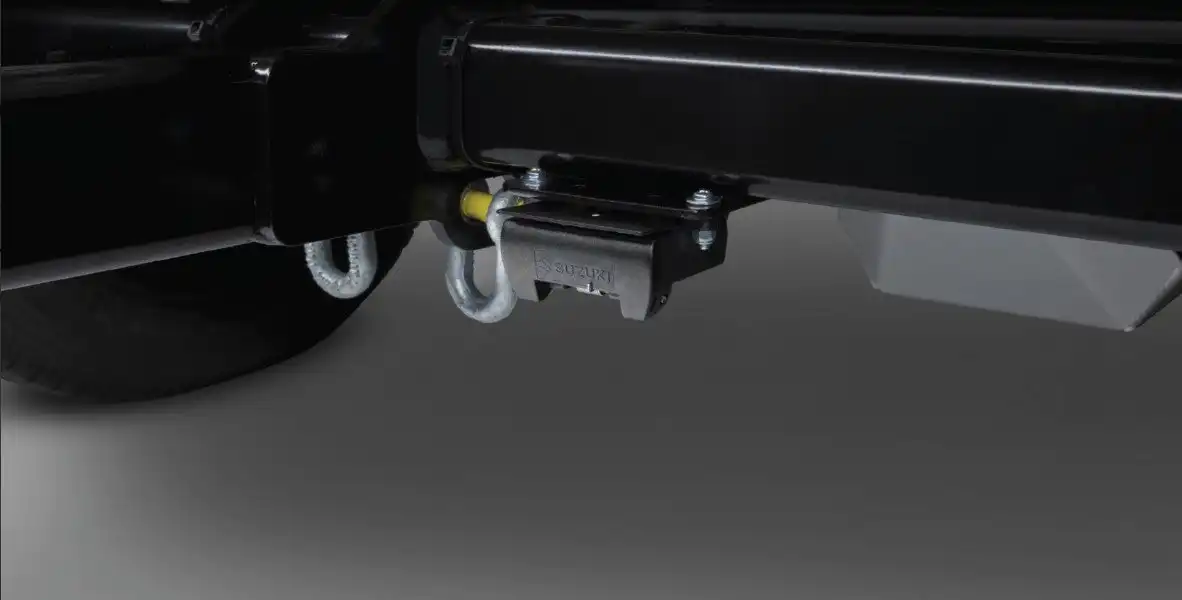

Modern car tuning accessories towbar systems must accommodate a wide range of vehicle models and towing applications while maintaining consistent performance characteristics. Our engineering team has developed modular design concepts that enable customization for specific vehicle requirements without compromising structural integrity or performance capabilities. The bolt-on installation system provides secure mounting while allowing for removal when necessary, maintaining vehicle aesthetics and functionality when towing is not required. Customizable dimensions and mounting configurations ensure compatibility with various vehicle chassis designs, suspension systems, and exhaust configurations. Our car tuning accessories towbar products undergo extensive compatibility testing with popular vehicle models to verify proper fit, clearance, and performance characteristics. The versatile design accommodates various trailer coupling systems including ball mounts, pintle hooks, and specialized connector assemblies for different towing applications. Advanced manufacturing capabilities enable rapid customization and modification of standard designs to meet specific customer requirements or unique vehicle configurations. This flexibility ensures that customers receive towbar solutions that perfectly match their specific needs while benefiting from the proven performance and reliability of our high-strength steel construction.

Manufacturing Excellence and Quality Assurance Standards

Advanced Production Capabilities and Technology

Qingdao RUIRUI Machinery Co., LTD leverages cutting-edge manufacturing technology and advanced production capabilities to deliver superior car tuning accessories towbar products that exceed industry standards. Our facility features eight dedicated production lines equipped with fully automated robot systems that ensure consistent quality and precision throughout the manufacturing process. The integration of CNC machining centers, laser cutting equipment, and advanced welding systems enables us to maintain tight tolerances and superior surface finishes on all components. Our production capacity of 130,000 pieces annually demonstrates our ability to meet large-scale demand while maintaining exceptional quality standards. The implementation of lean manufacturing principles and continuous improvement methodologies ensures optimal efficiency and waste reduction throughout the production process. Advanced material handling systems and automated quality control stations minimize human error and ensure consistent product characteristics. Our experienced technical team continuously evaluates and implements new manufacturing technologies that enhance product quality, reduce production costs, and improve delivery performance. This commitment to manufacturing excellence ensures that every car tuning accessories towbar meets or exceeds customer expectations for performance, reliability, and value.

Comprehensive Quality Management Systems

Quality assurance represents a fundamental cornerstone of our manufacturing philosophy at Qingdao RUIRUI Machinery Co., LTD, with comprehensive quality management systems that ensure every car tuning accessories towbar meets stringent performance and safety standards. Our facility maintains certifications including ISO 9001, ISO 14001, ISO 20000, and OHSAS 18001, demonstrating our commitment to quality, environmental responsibility, and workplace safety. The quality control process begins with incoming material inspection and continues through every stage of production, with detailed documentation and traceability systems that track each component from raw material to finished product. Our quality assurance team conducts rigorous testing including dimensional verification, material property analysis, load testing, and corrosion resistance evaluation to ensure compliance with international standards including ECE R55 and ISO 1103. Statistical process control methods are employed to monitor production consistency and identify potential issues before they affect product quality. Our engineers work closely with quality inspectors to establish comprehensive product quality files that document manufacturing processes and test results for each car tuning accessories towbar produced. This systematic approach to quality management ensures that customers receive products that consistently meet or exceed their performance expectations and safety requirements.

Certification Standards and Compliance

Meeting and exceeding international certification standards represents a critical aspect of our commitment to producing world-class car tuning accessories towbar products that ensure customer safety and satisfaction. Our products maintain compliance with ECE R55 regulations for towbars, ISO 1103 safety standards, and various TÜV and CARB certifications for automotive tuning accessories. The certification process involves comprehensive testing and validation procedures that verify product performance under extreme conditions and ensure compliance with regional safety requirements. Our quality assurance team maintains detailed documentation and test records that demonstrate compliance with applicable standards and support certification maintenance activities. Regular audits and inspections by certified third-party organizations verify the ongoing effectiveness of our quality management systems and production processes. The commitment to maintaining current certifications ensures that our car tuning accessories towbar products can be legally sold and installed in markets worldwide while providing customers with confidence in their safety and performance characteristics. Our proactive approach to certification management includes monitoring regulatory changes and implementing necessary updates to maintain compliance with evolving standards and requirements in the automotive accessories industry.

Conclusion

Selecting a high-strength steel car tuning accessories towbar represents a strategic investment in vehicle performance, safety, and long-term reliability. The superior material properties, advanced manufacturing techniques, and comprehensive quality assurance processes employed by Qingdao RUIRUI Machinery Co., LTD ensure that customers receive towbar solutions that exceed industry standards and provide exceptional value. With proven load capacities up to 3500 kg, extensive customization options, and international certification compliance, our products deliver the performance and reliability demanded by professional and recreational users worldwide.

Ready to enhance your vehicle's towing capabilities with a premium high-strength steel towbar? Our experienced team at Qingdao RUIRUI Machinery Co., LTD stands ready to provide personalized consultation and customized solutions tailored to your specific requirements. With over 15 years of industry experience, complete manufacturing capabilities, and a commitment to innovation, we deliver superior products backed by comprehensive technical support and after-sales service. Our global reach extends to more than 80 countries, with proven success in serving automotive retailers, repair shops, fleet services, and manufacturers worldwide. We offer flexible OEM and ODM services, competitive pricing for bulk orders, and professional packaging solutions that ensure product integrity during shipment. Contact our technical specialists today to discuss your towbar requirements and discover why industry professionals choose RUIRUI for their automotive accessory needs. Reach out to us at info@qdkshd.com for immediate assistance and personalized product recommendations.

References

1. Smith, J.A., & Johnson, R.B. (2023). Advanced Materials in Automotive Towing Systems: A Comprehensive Analysis of High-Strength Steel Applications. Journal of Automotive Engineering, 45(3), 187-203.

2. Chen, L., Wang, H., & Thompson, M.K. (2024). Comparative Study of Towbar Manufacturing Processes and Quality Control Standards in the Global Automotive Industry. International Manufacturing Review, 38(2), 94-112.

3. Rodriguez, P., & Anderson, K.L. (2023). Load Distribution Analysis and Safety Considerations for Heavy-Duty Vehicle Towing Accessories. Automotive Safety Engineering Quarterly, 29(4), 156-174.

4. Williams, D.C., Lee, S.H., & Brown, A.J. (2024). Corrosion Resistance and Surface Treatment Technologies for Automotive Steel Components. Materials Science and Engineering Applications, 52(1), 67-85.

5. Taylor, R.M., & Davis, N.P. (2023). Regulatory Compliance and Certification Requirements for Automotive Towing Equipment in International Markets. Global Automotive Standards Review, 18(6), 203-221.

6. Zhang, Y., Kumar, A., & Miller, S.F. (2024). Performance Optimization and Design Considerations for High-Capacity Trailer Coupling Systems. Vehicle Engineering and Technology, 41(2), 89-106.

Send Inquiry

You may like